Slic3r

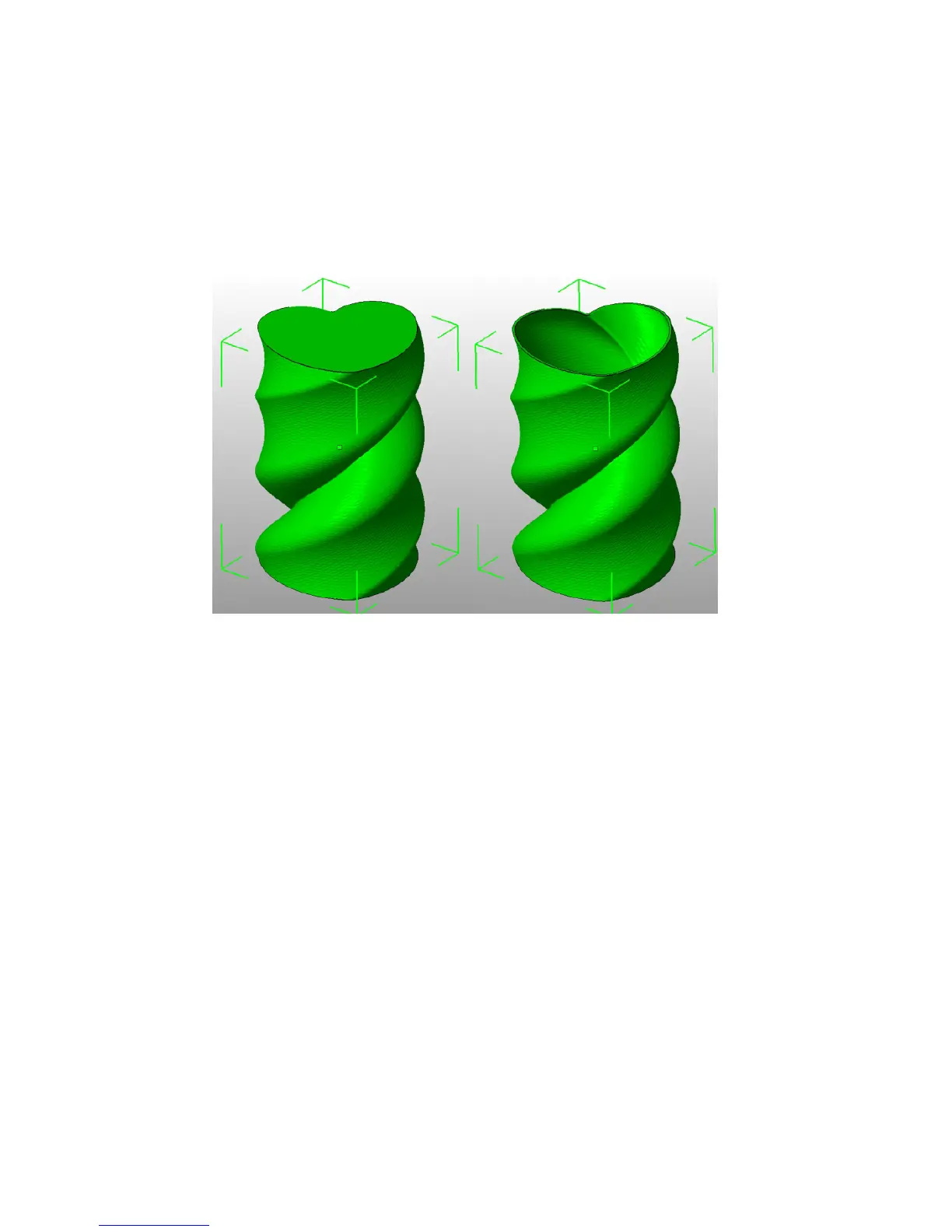

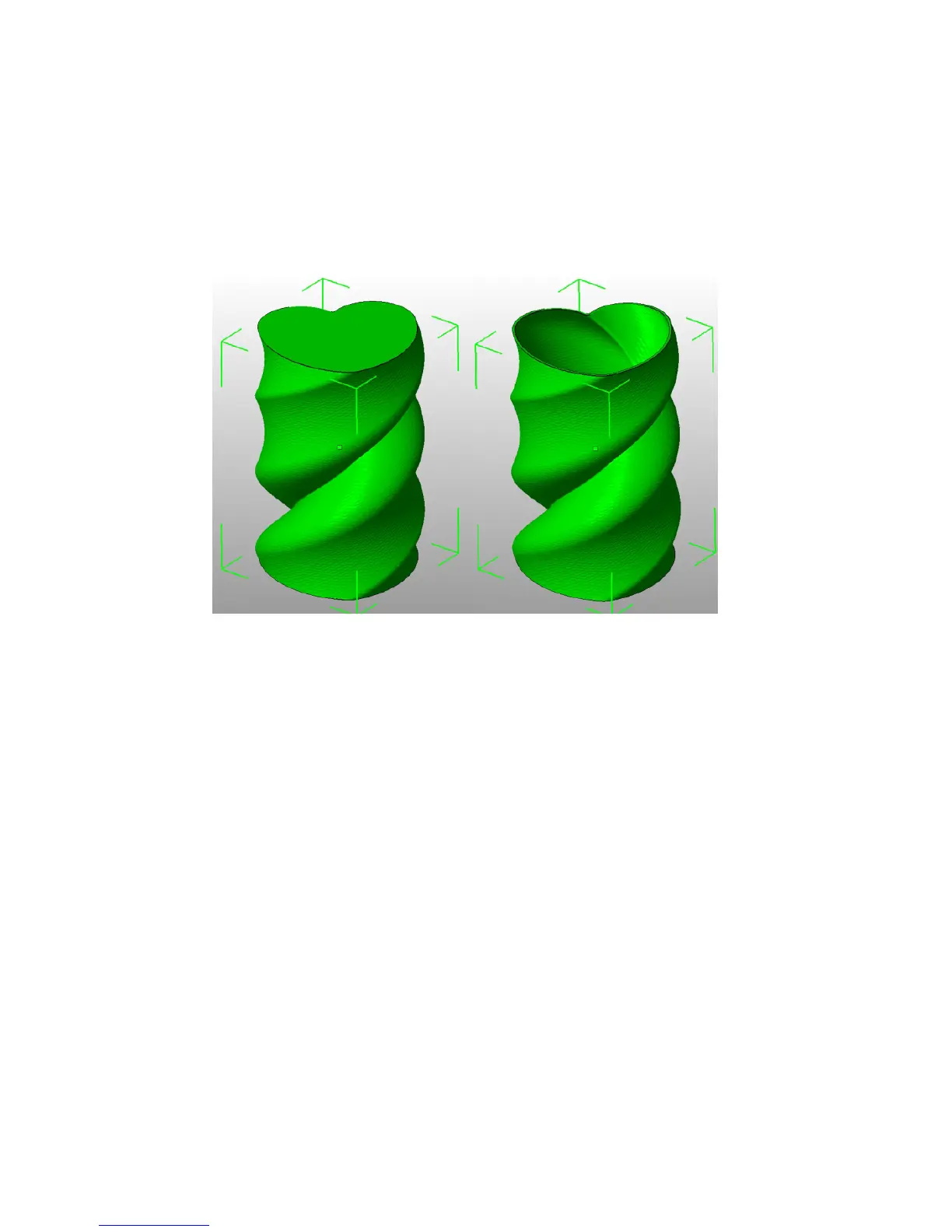

Another tip to consider: Setting the top solid layer to zero, and setting

the infill also to zero, will result in a hollow receptacle, ideal for turning

models into vases

13

for example. Here manipulating the settings within

Slic3r can be used to generate different kinds of prints, and not only be

used to control surface accuracy.

Figure 2.16: Creating a vase from a solid model.

Infill. Fill density is defined on a scale of between 0 and 1, where 1 is

100% and 0.4 would be 40%. For the majority of cases it makes no sense to

100% fill the model with plastic, this would be a waste of material and take

a long time. Instead, most models can be filled with less material which is

then sandwiched between layers filled at 100% (see Solid layers above).

A density value of 0.4 is enough to give almost all models good

mechanical strength. A value of 0.2 is usually the minimum required to

support flat ceilings.

Slic3r offers several fill patterns which will be discussed in more depth

in subsection 2.5 - Infill Choices. Choosing a Fill pattern will depend

on the kind of model, the desired structural strength, print speed, and

personal taste. The more exotic fill methods are usually too slow and

unnecessarily complex for most use cases, and so most of the time the infill

13

http://slic3r.org/blog/tip-printing-vases

74

Loading...

Loading...