214683 99 Revision A

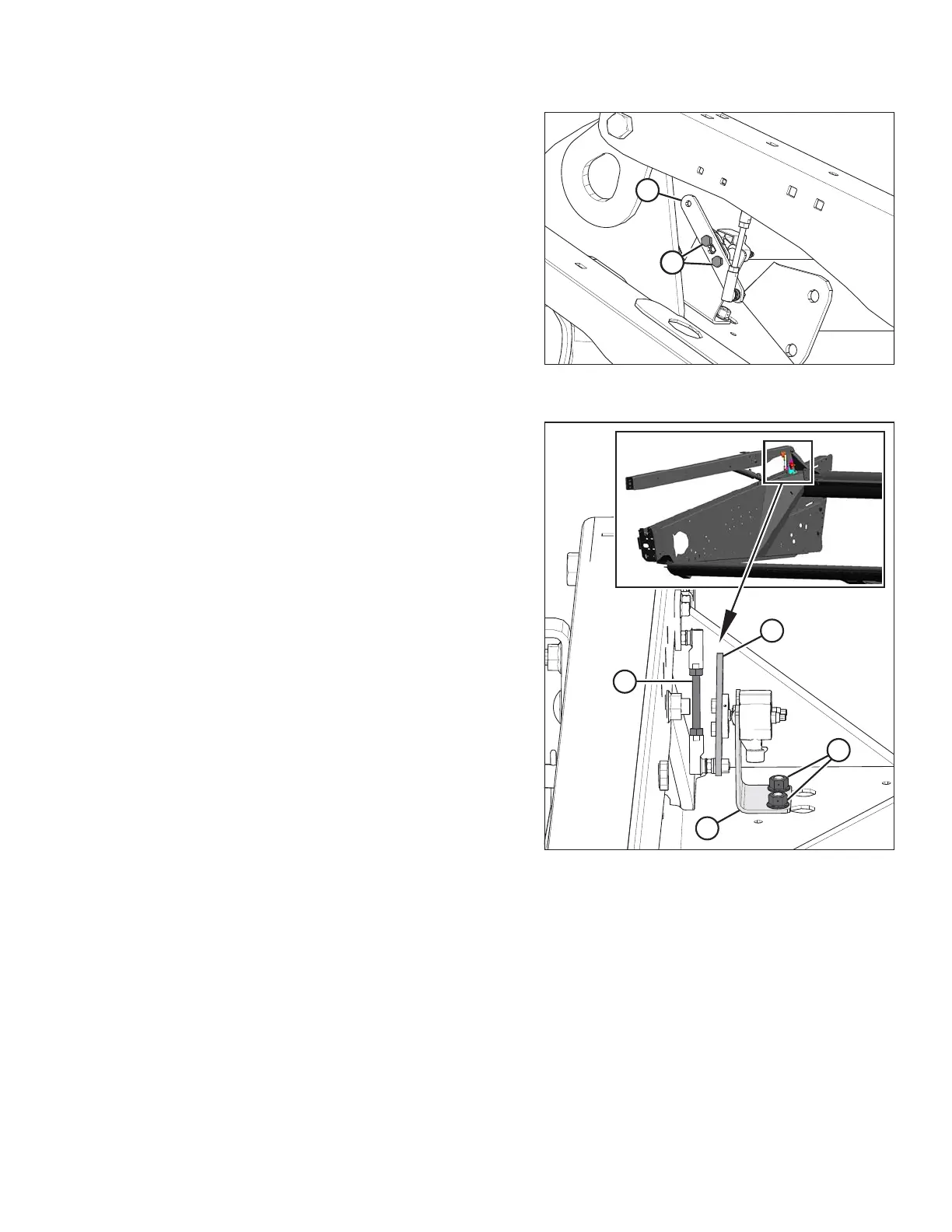

Figure 3.104: Reel Height Sensor – Right

Reel Arm

7. Connect sensor arm (B) using retain hex head bolts (A).

Torque head bolts (A) to 4 Nm (35 lbf·in.).

8. Connect the sensor to the harness.

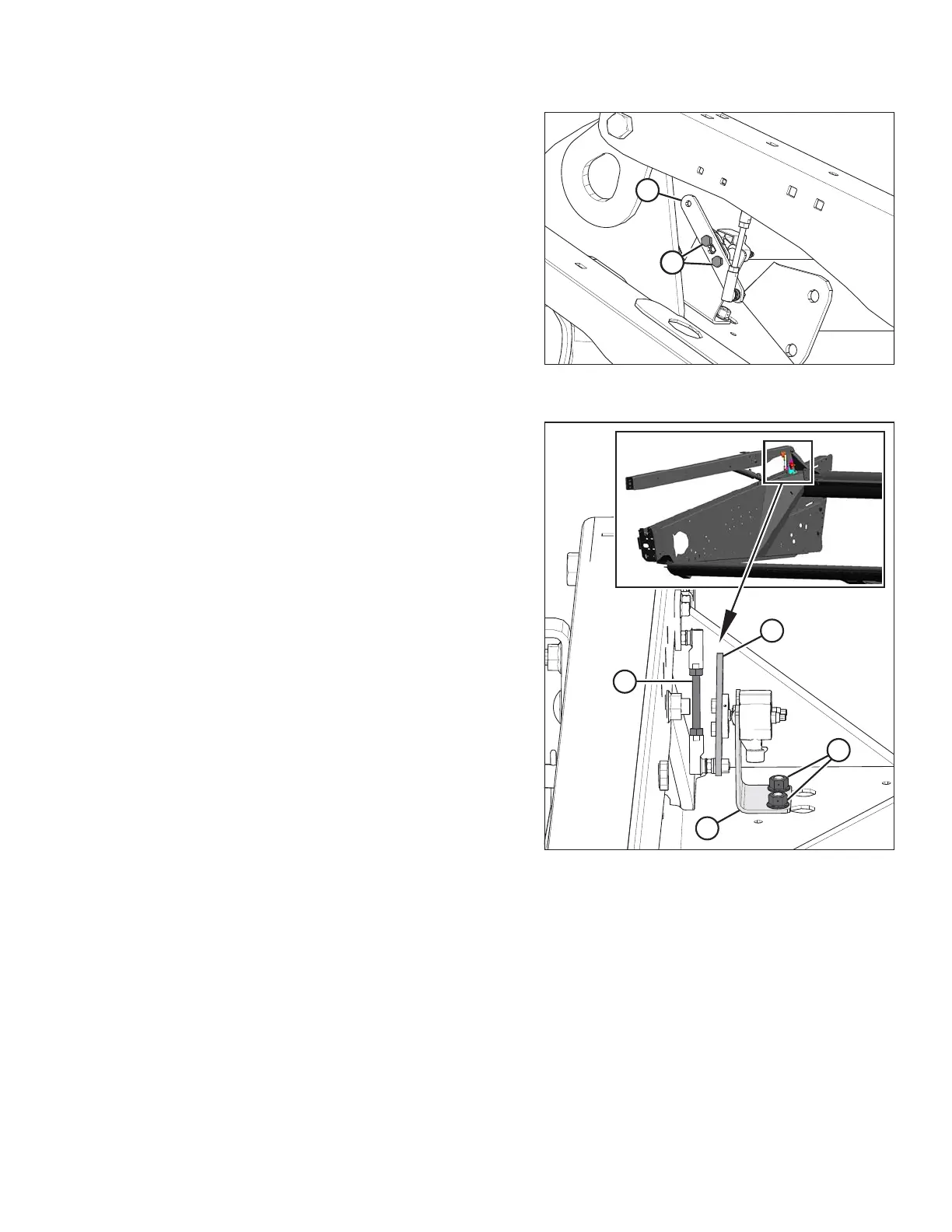

Figure 3.105: Reel Height Sensor – Right Reel

Arm (Front View)

9. Check that sensor arm and the threaded rod are

parallel. If not, loosen two center lock flange nuts (A),

and adjust sensor mounting bracket (B) until the

threaded rod (C) is parallel with the sensor arm (D).

Tighten center lock flange nuts.

10. Check the sensor voltage range. Refer to Checking and

Adjusting Reel Height Sensor, page 96.

3.7.11 Reel Fore-Aft Position

Reel fore-aft position is a critical factor for achieving the best results in adverse conditions. The factory-set reel

position suits normal conditions, but the fore-aft position can be adjusted as required using the controls inside the

cab.

The reel on non-European-configured headers can be moved approximately 227 mm (9 in.) farther aft by

repositioning the fore-aft cylinders on the header’s reel arms to accommodate certain crop conditions. Refer to

Repositioning Fore-Aft Cylinders on Non-European-Configured Headers, page 101.

OPERATION

Loading...

Loading...