214683 327 Revision A

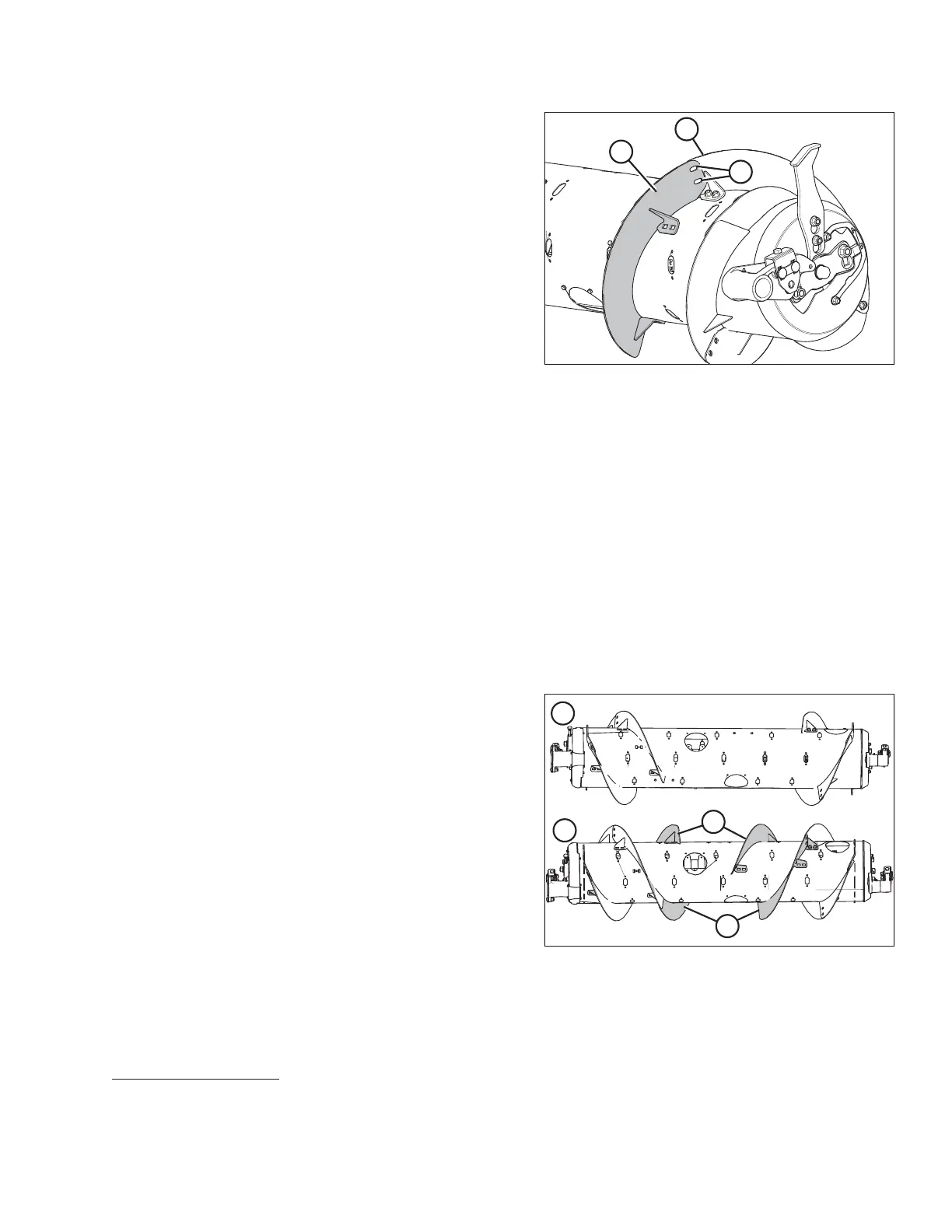

Figure 4.41: Right Side of Auger

26. Place bolt-on flighting (A) outboard of the other

flighting (B) on the right side of the auger as shown.

27. Temporarily secure bolt-on flighting (A) with two button

head bolts and nuts at location (C).

28. Repeat Steps 20, page 326 to for both pieces of

flighting on the right side of the auger.

29. Install flighting slot plugs (MD #213084) in the flighting

mounting locations and secure with M6 bolts and

tee nuts.

30. Torque all nuts and bolts to 47 Nm (35 lbf·ft) to eliminate

deflection on flighting, then retorque them to 58–64 Nm

(43–47 lbf·ft).

NOTE:

The flighting should fit tightly against the auger tube; however, gaps are not uncommon. Crop material may collect

in these gaps, but this should not affect performance. If desired, use silicone sealant to fill these gaps.

31. Add or remove auger fingers to optimize feeding for your combine and crop conditions. Refer to Installing Feed

Auger Fingers, page 431 or Removing Feed Auger Fingers, page 429.

32. If not adding or removing auger fingers, reinstall all access covers and secure with bolts. Coat bolts with

medium-strength threadlocker (Loctite

®

243 or equivalent) and torque to 8.5 Nm (75 lbf∙ in).

4.1.9 Converting from Narrow Configuration to Ultra Narrow Configuration

Two kits of either MD #287032 or B6400

50

and some hole-drilling are required to convert to this configuration. Extra

hardware is included in these kits. Be sure to use the correct hardware at the correct location to prevent damage

and to maximize performance.

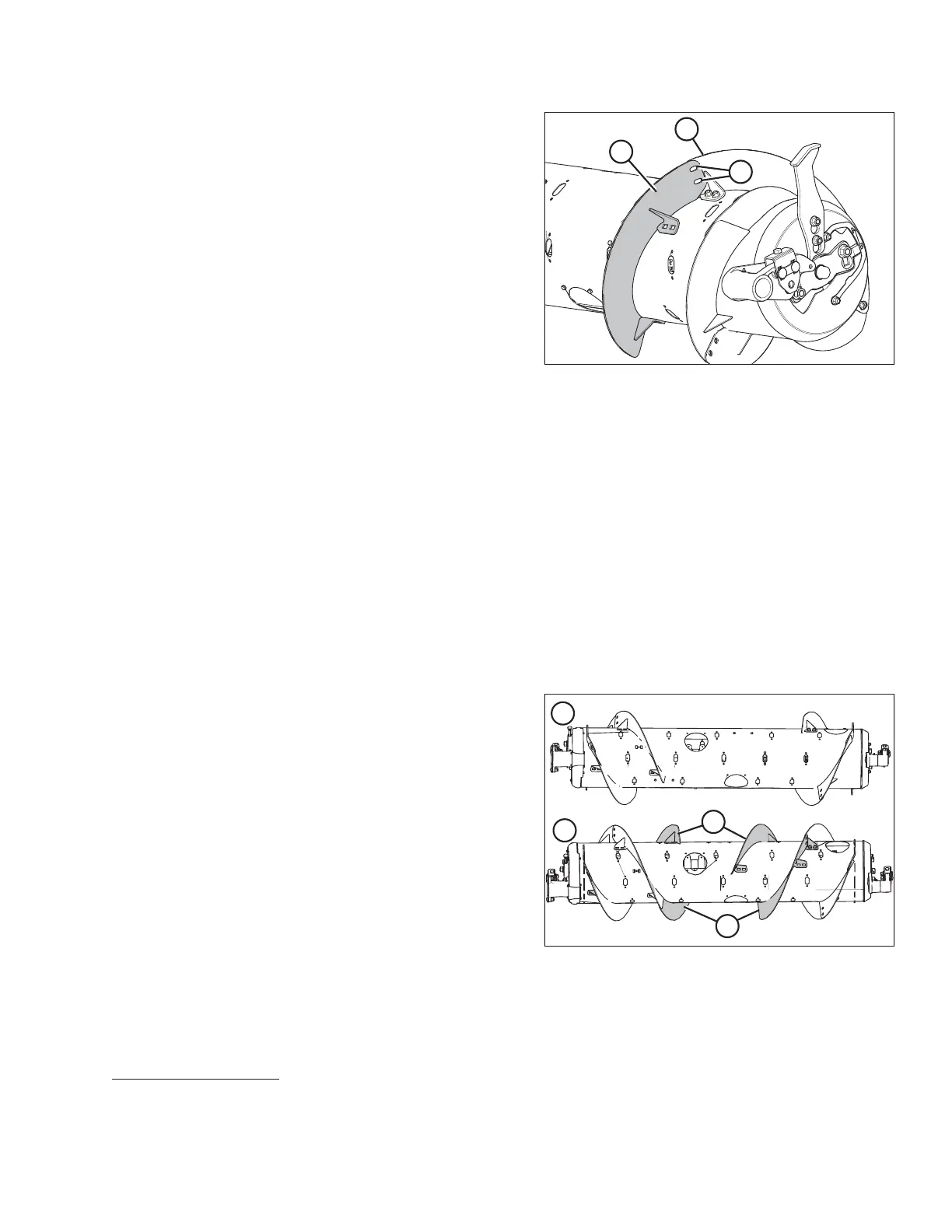

Figure 4.42: Auger Configurations (Rear View)

1 - Narrow Configuration 2 - Ultra Narrow Configuration

NOTE:

Additional holes on the auger are needed before these

flightings (A) can be installed.

HEADER ATTACHMENT/DETACHMENT

50. MD #287032 is available only through MacDon Parts. B6400 is available only through Whole Goods. Both kits

contain wear-resistant flightings.

Loading...

Loading...