214683 179 Revision A

Adjusting the Header Raise/Lower Rate (Gleaner R65/R66/R75/R76 and Pre-2016 S Series)

NOTE:

Changes may have been made to the combine controls or display since this document was published. Refer to the

combine operator’s manual for updates.

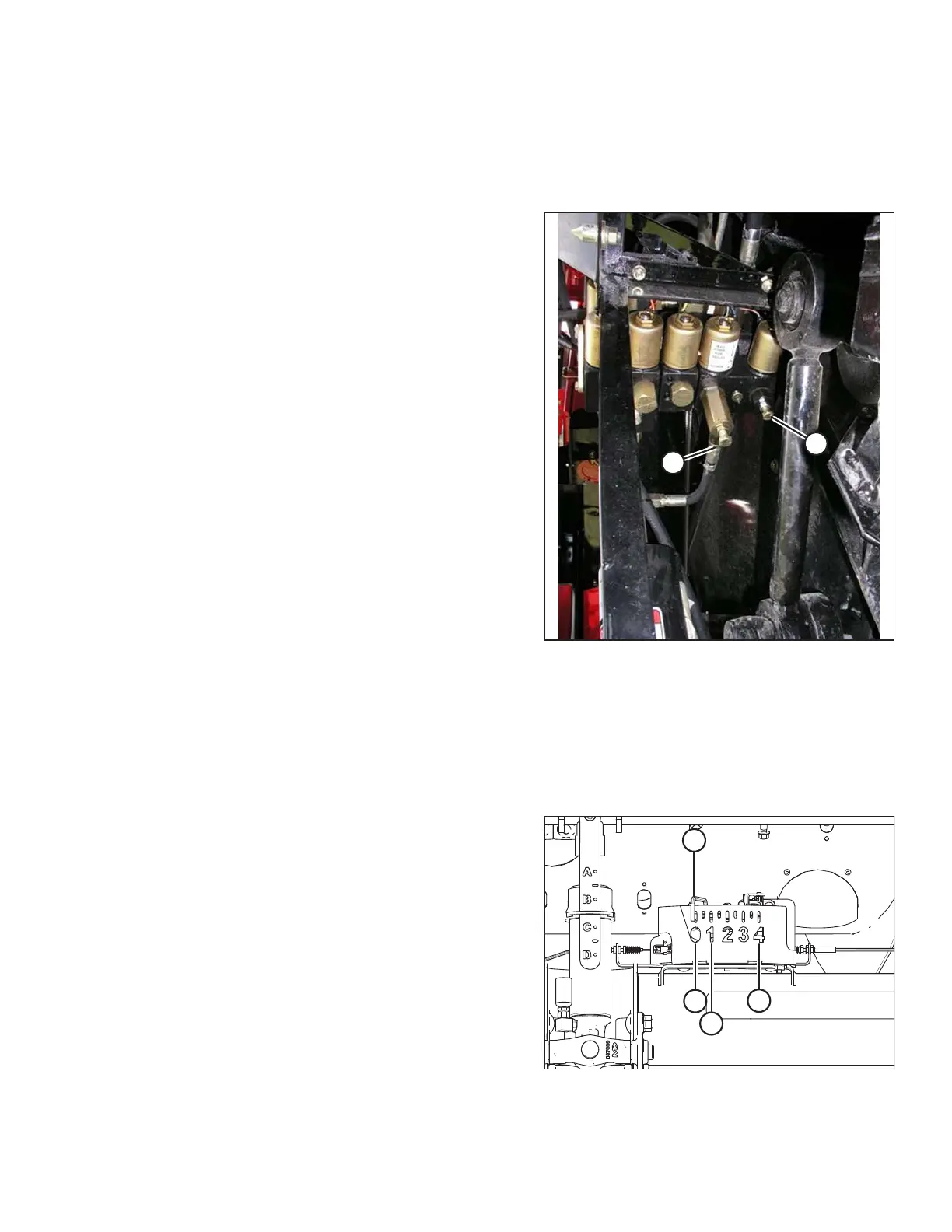

Figure 3.273: Header Raise and Lower

Adjustable Restrictors

The auto header height control (AHHC) system’s stability is

affected by hydraulic flow rates. Ensure that the header

raise (A) and header lower (B) adjustable restrictors in the

hydraulic manifold are adjusted so that it takes

approximately 6 seconds to raise the header from ground

level to maximum height (hydraulic cylinders fully

extended), and approximately 6 seconds to lower the

header from maximum height to ground level.

If there is too much header movement (for example,

hunting) when the header is on the ground, adjust the lower

rate to a slower rate of drop: 7 or 8 seconds.

NOTE:

Make this adjustment with the hydraulic system at normal

operating temperature (54.4°C [130°F]) and the engine

running at full throttle.

Adjusting Ground Pressure (Gleaner R65/R66/R75/R76 and Pre-2016 S Series)

NOTE:

Changes may have been made to the combine controls or display since this document was published. Refer to the

combine operator’s manual for updates.

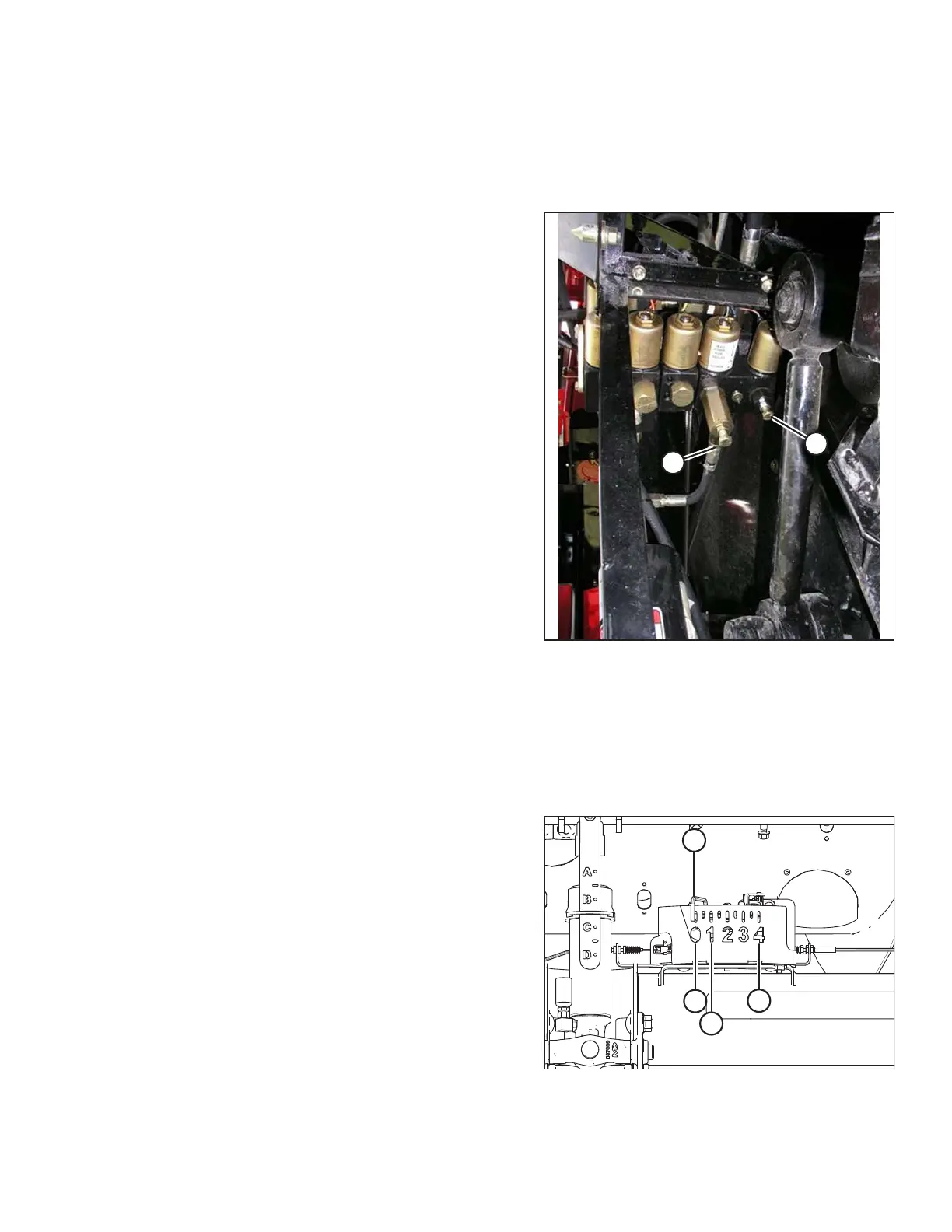

Figure 3.274: Float Indicator Box

NOTE:

The indicator (A) should be at position 0 (B) with the header

152 mm (6 in.) off the ground. If not, the float sensor output

voltage should be checked. Refer to Step 4, page 128.

When the header is on the ground, the indicator should be

at position 1 (C) for low ground pressure, and at position

4 (D) for high ground pressure. Crop and soil conditions

determine the amount of float to use. The ideal setting is as

light as possible without header bouncing or missing crop.

Operating with heavy settings prematurely wears the

cutterbar wearplates.

OPERATION

Loading...

Loading...