214683 465 Revision A

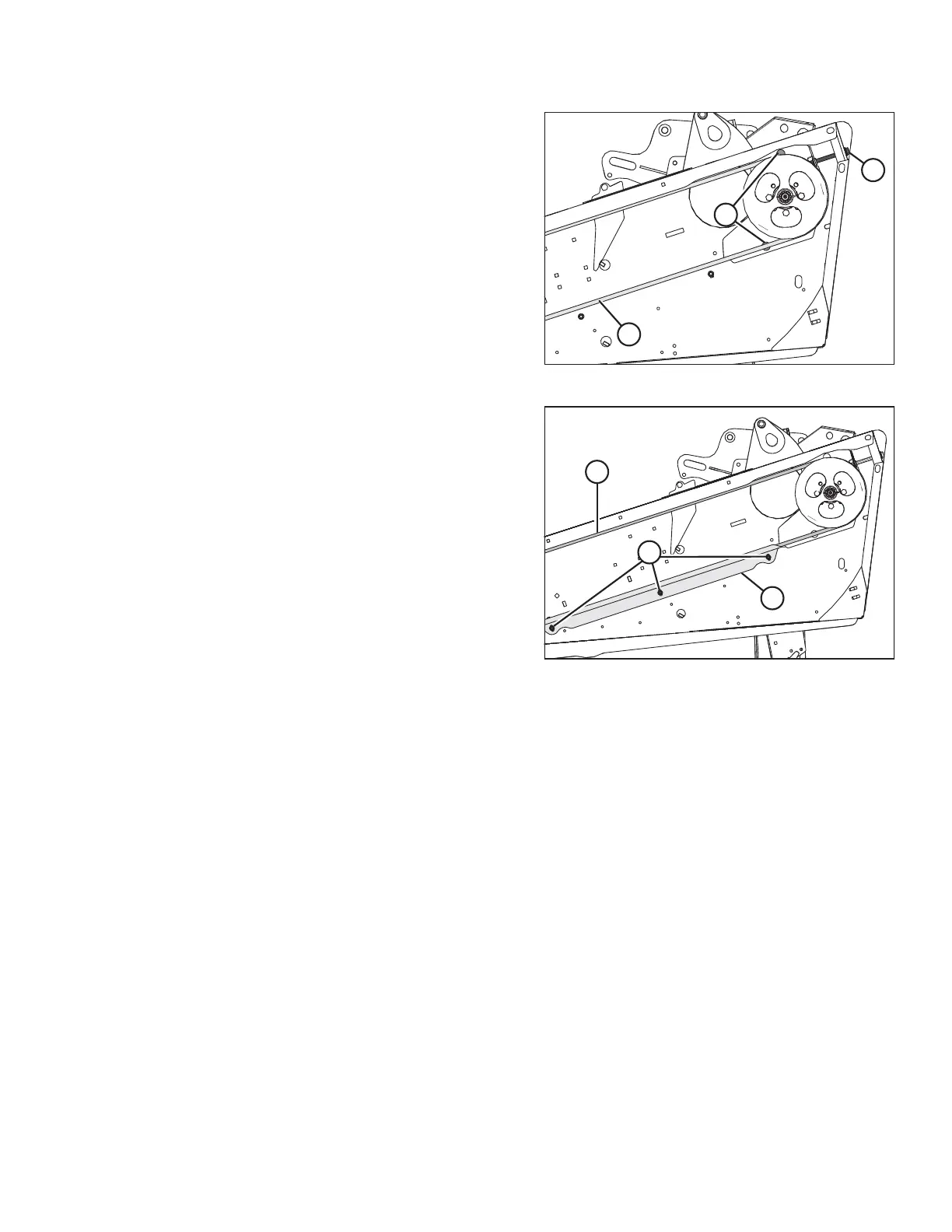

Figure 5.138: Knife Drive

NOTE:

Belt guide removed for illustration purposes.

3. Loosen the two bolts (A) securing the motor assembly

to the header endsheet.

4. Check drive belt tension. A properly tensioned drive

belt (C) should deflect 24–28 mm (15/16–1-1/8 in.)

when 133 N (30 lbf) of force is applied at the midspan. If

the belt needs to be tensioned, turn the adjuster bolt (B)

clockwise to move the drive motor until proper tension

is set.

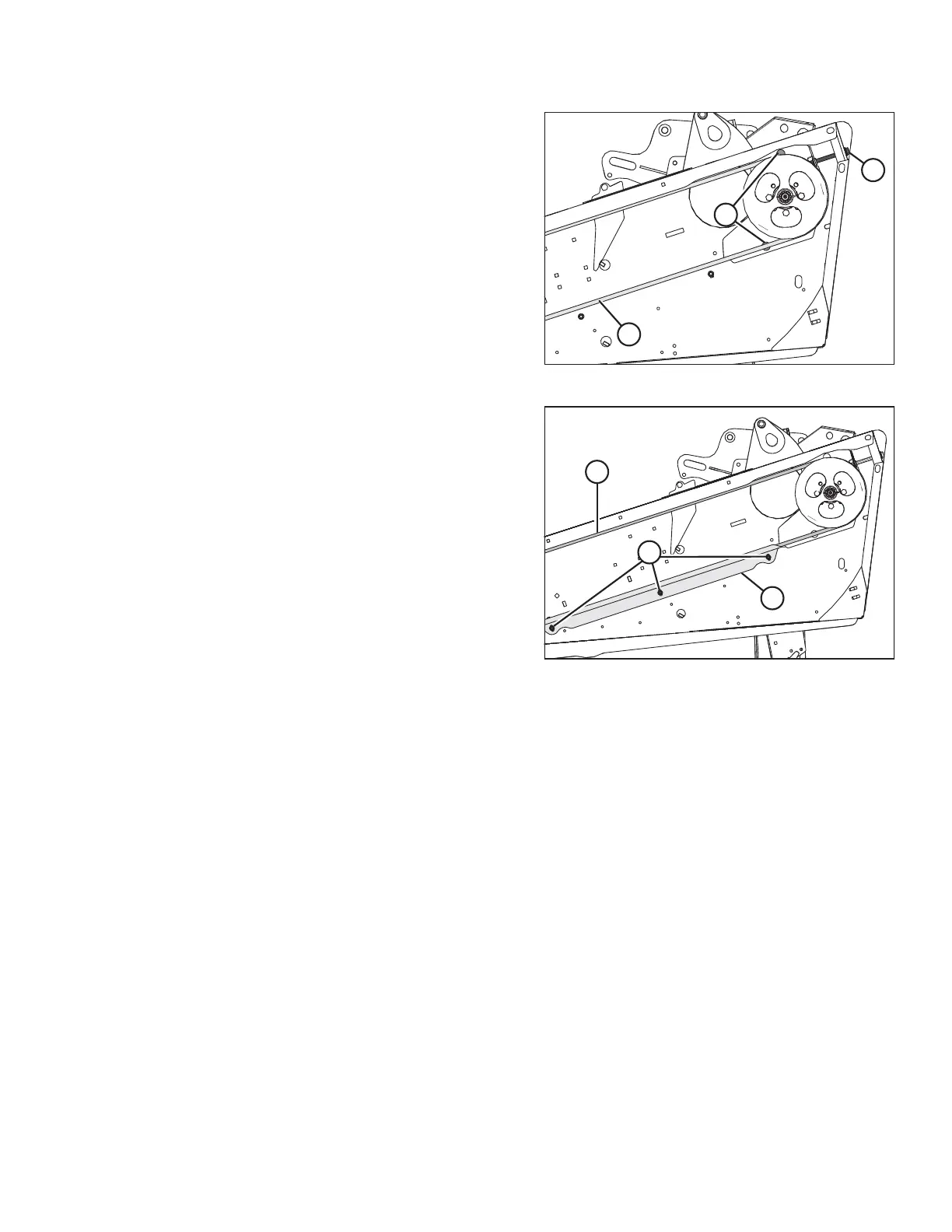

Figure 5.139: Knife Drive

5. Ensure the clearance between belt (A) and belt

guide (B) is 1 mm (1/16 in.).

6. Loosen the three bolts (C), and adjust the position of

guide (B) as required.

7. Tighten the three bolts (C).

8. Close the endshield. Refer to Closing Endshields, page

34.

NOTE:

Readjust the tension of a new belt after a short run-in

period (about 5 hours).

9. Double-knife headers only: Repeat procedure on the

other side of the header.

MAINTENANCE AND SERVICING

Loading...

Loading...