6.1 PROFINET communication

99

NSOLL_A: set speed A(16Bit), N2.

Servo parameter P310 is used as the reference variable, and the speed instruction value

corresponding to N2 normalized data sent by PLC is used as the speed instruction of the servo

driver. See Section 6.1.4 for details.

NSOLL_B: set speed B(32Bit), N4.

Servo parameter P310 is used as the benchmark variable, and the speed instruction value

corresponding to N4 type normalized data sent by PLC is used as the speed instruction of the

servo driver. See Section 6.1.4 for details.

STW2: Control word 2, U16.

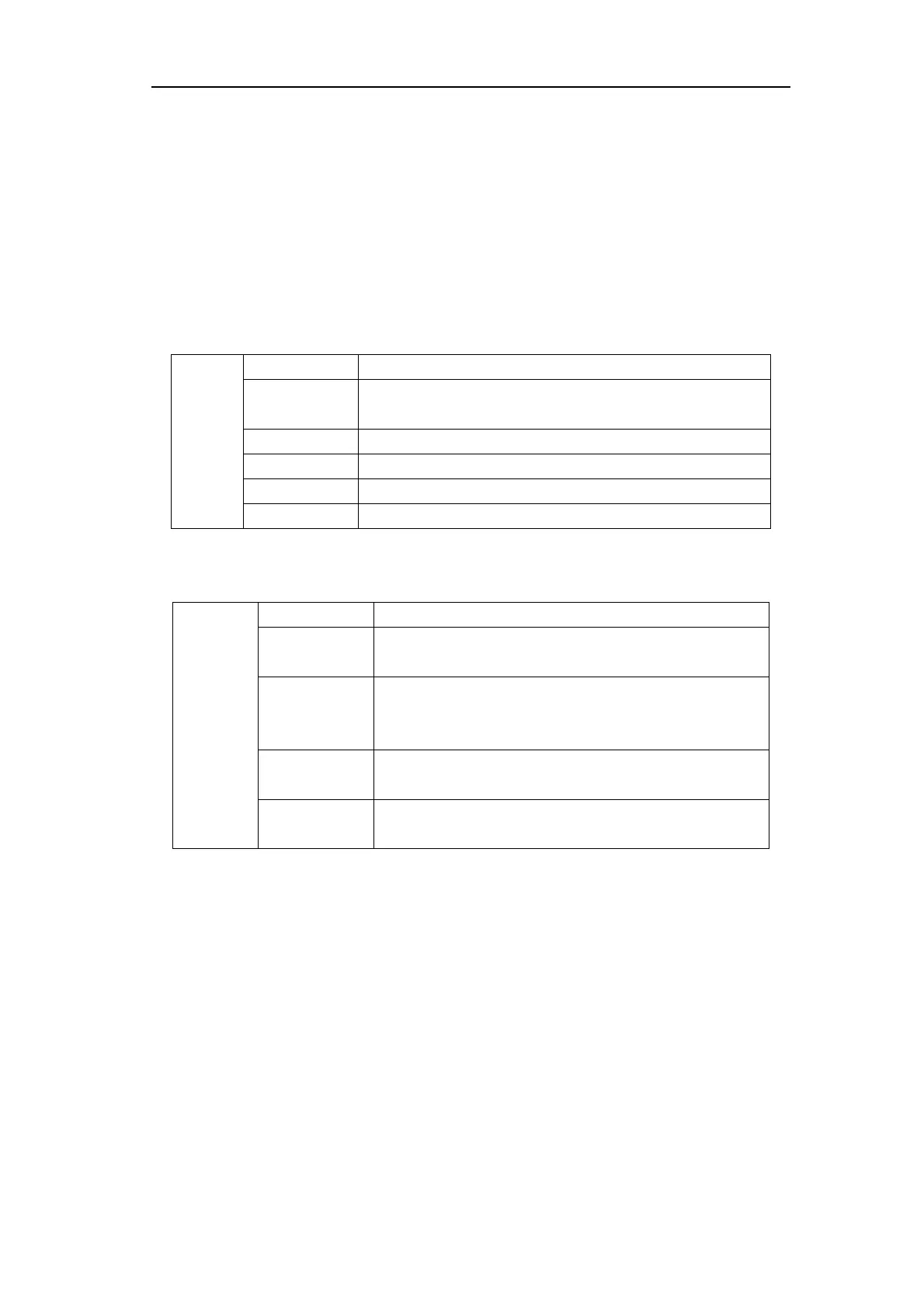

STW2

Signal Describe

STW2.0~

STW2.11

Reserved

STW2.12 Main life symbol, Bit0

STW2.13 Main life symbol, Bit1

STW2.14 Main life symbol, Bit2

STW2.15 Main life symbol, Bit3

G1_STW: Encoder 1 control word, U16.

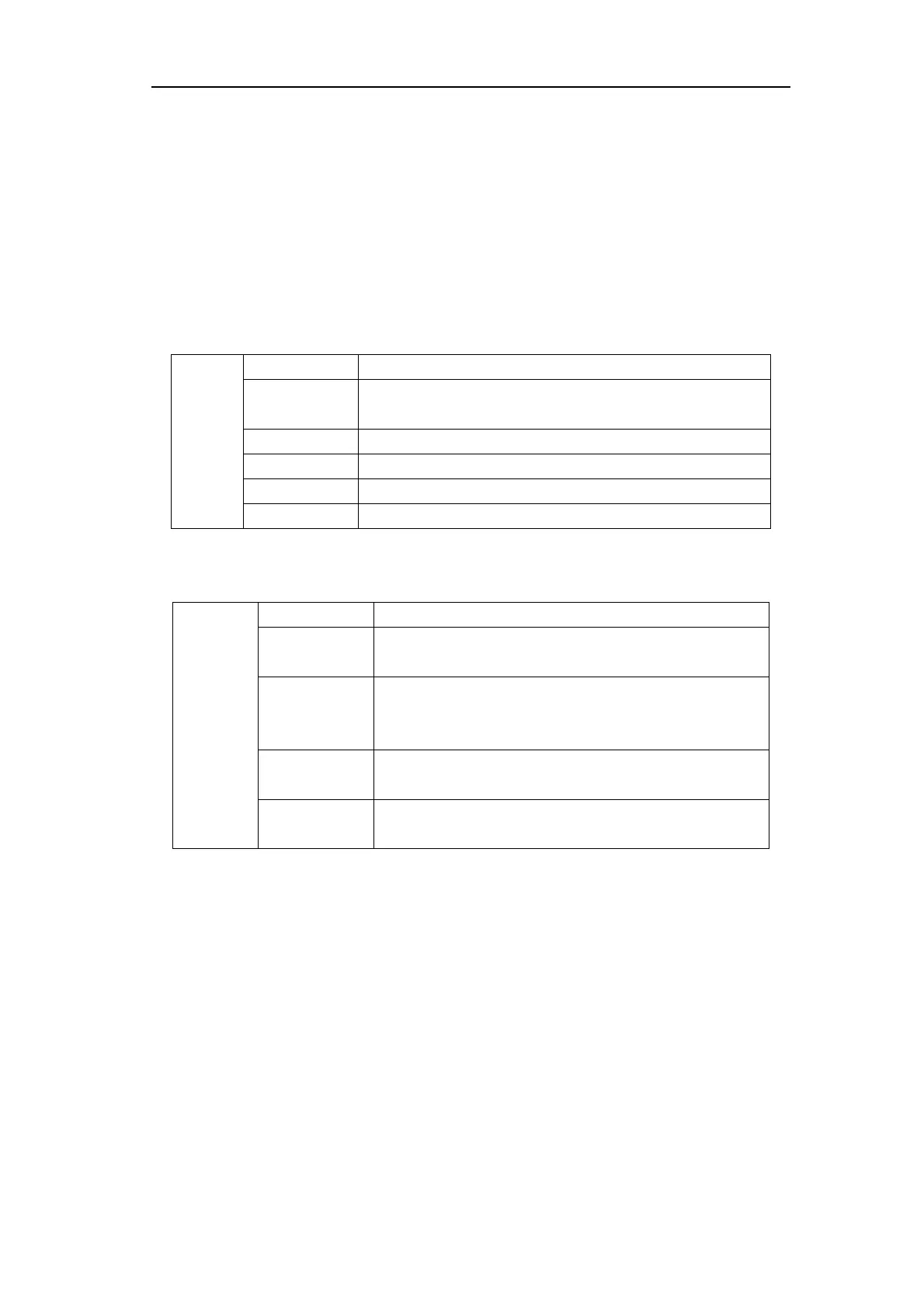

G1_STW

Signal Describe

G1_STW.0~

G1_STW.11

Reserved

G1_STW.13

1: Request the additional cycle cycle transmission for the

absolute position in Gx_XIST2.

0: No request.

G1_STW.14

1: Requests the resident shaft encoder.

0: No request.

G1_STW.15

1: Encoder fault confirmation (0→1 hop).

0: Indicates nonsense.

MOMRED: Torque reduction set point, N2.

Servo parameter P312 is used as the reference variable. The torque reduction instruction

corresponding to N2 type normalized data sent by PLC takes effect after recalculating the

positive and negative torque limit value inside the servo. For details, see Section 6.1.4.

XERR: DSC position deviation, I32.

KPC: DSC position control gain, I32.

Loading...

Loading...