5-3

Turn on the gas and reconnect dryer to

power. Run the dryer in a heat cycle. Read

the manometer with the burner ON, (check

for gas leaks).

When the gas is on, the amount of water

column present is equal to the total amount

of deflection shown in the manometer.

Once the test is completed, make sure the

tapered fitting is removed from the gas

valve and the plug is repositioned into the

gas valve and resealed with pipe seal.

Check for gas leaks again with a soap or

bubble solution. DO NOT USE OPEN

FLAME TO CHECK FOR GAS LEAKS.

IF HIGH WATER COLUMN PRESSURE IS

DETECTED: the gas flame can damage

the flame spreader on the burner. (This can

be caused by the wrong orifice, improper air

mixture or high gas pressure. If pressure

is higher than expected, contact the local

gas utilities company to check the outside

regulator.

8.

9.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

How to Use:

Unplug dryer of disconnect power.

Shut off gas supply to the dryer.

Remove front panel.

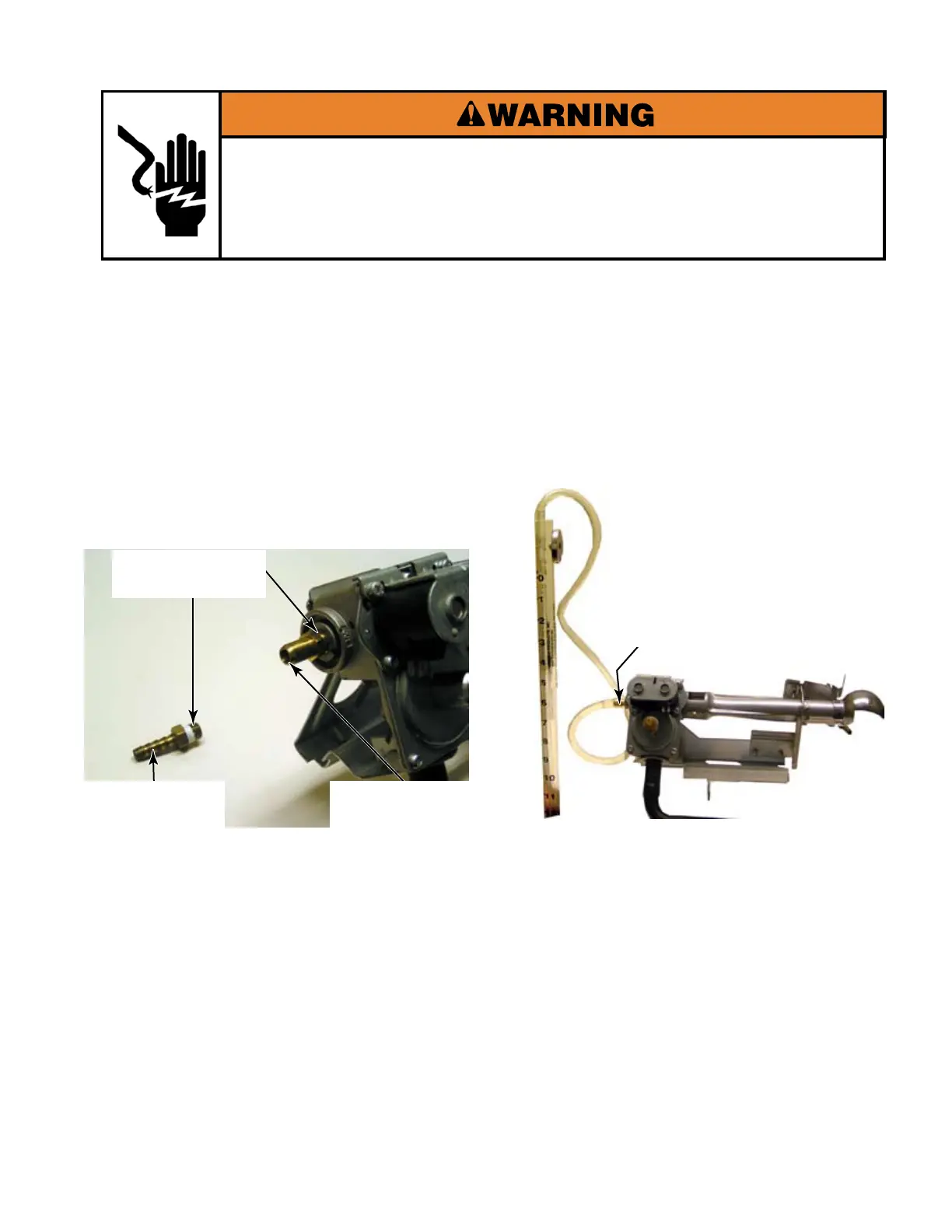

Install a 1/4” tapered fitting at the gas valve

pressure tap. Use thread seal tape or

compound on fitting.

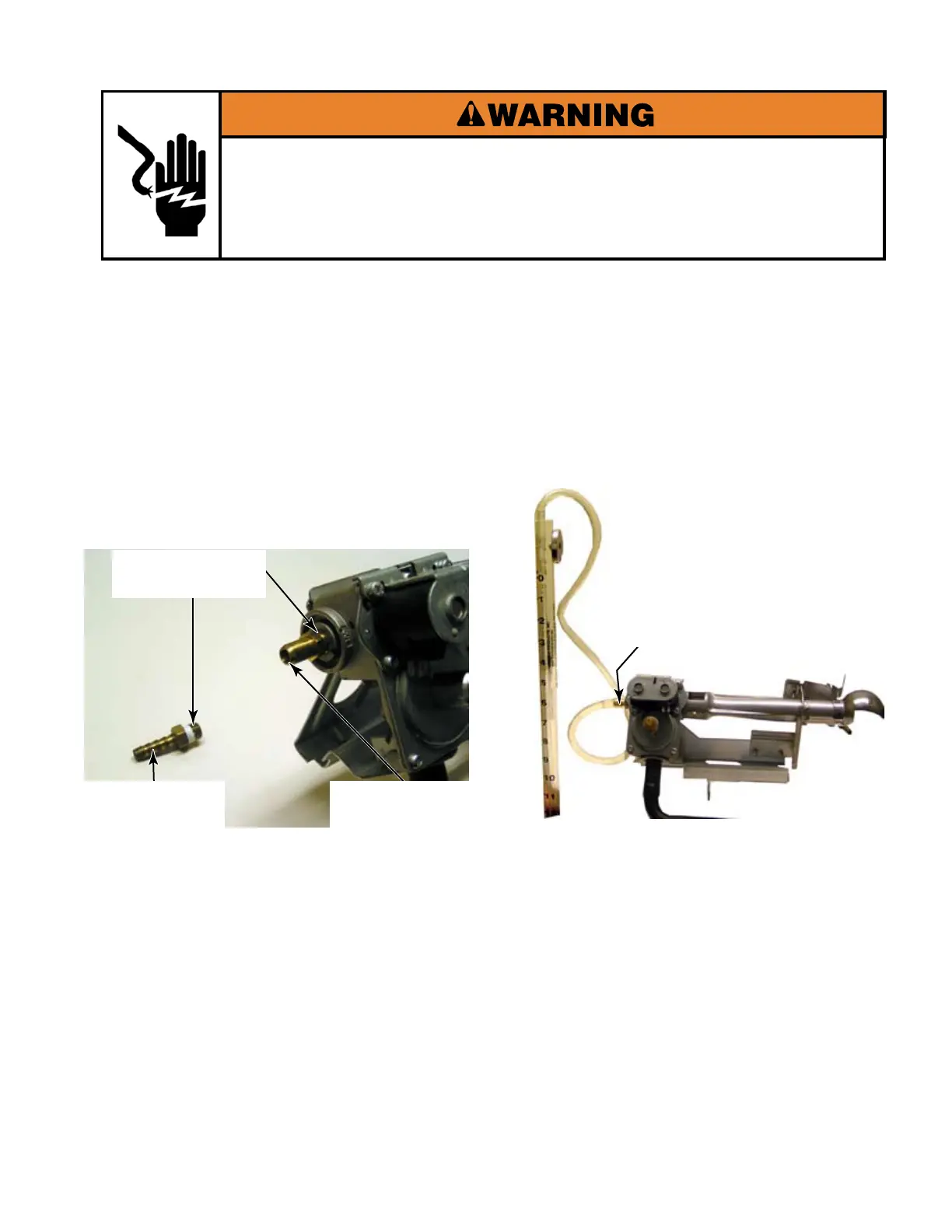

Fill the manometer tube with water until

each side equalizes at “0” water column.

Push the end of the manometer hose onto

the pressure tap located on the gas valve.

Connect hose to one end of the manometer.

1.

2.

3.

4.

5.

6.

7.

1/4” Tapered

Fitting

Smooth

Pressure Tap

Pressure

Tap

Barbed

Pressure Tap

Loading...

Loading...