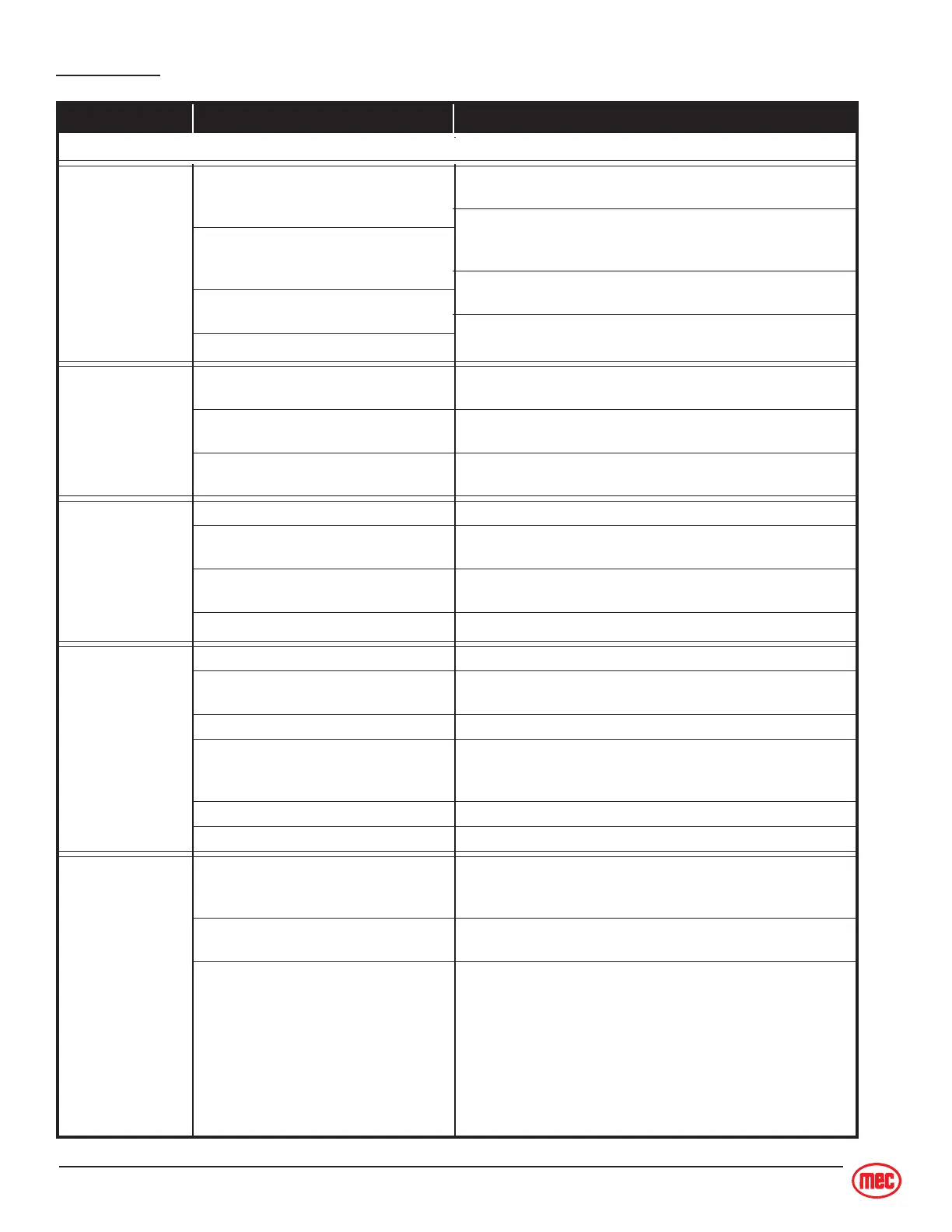

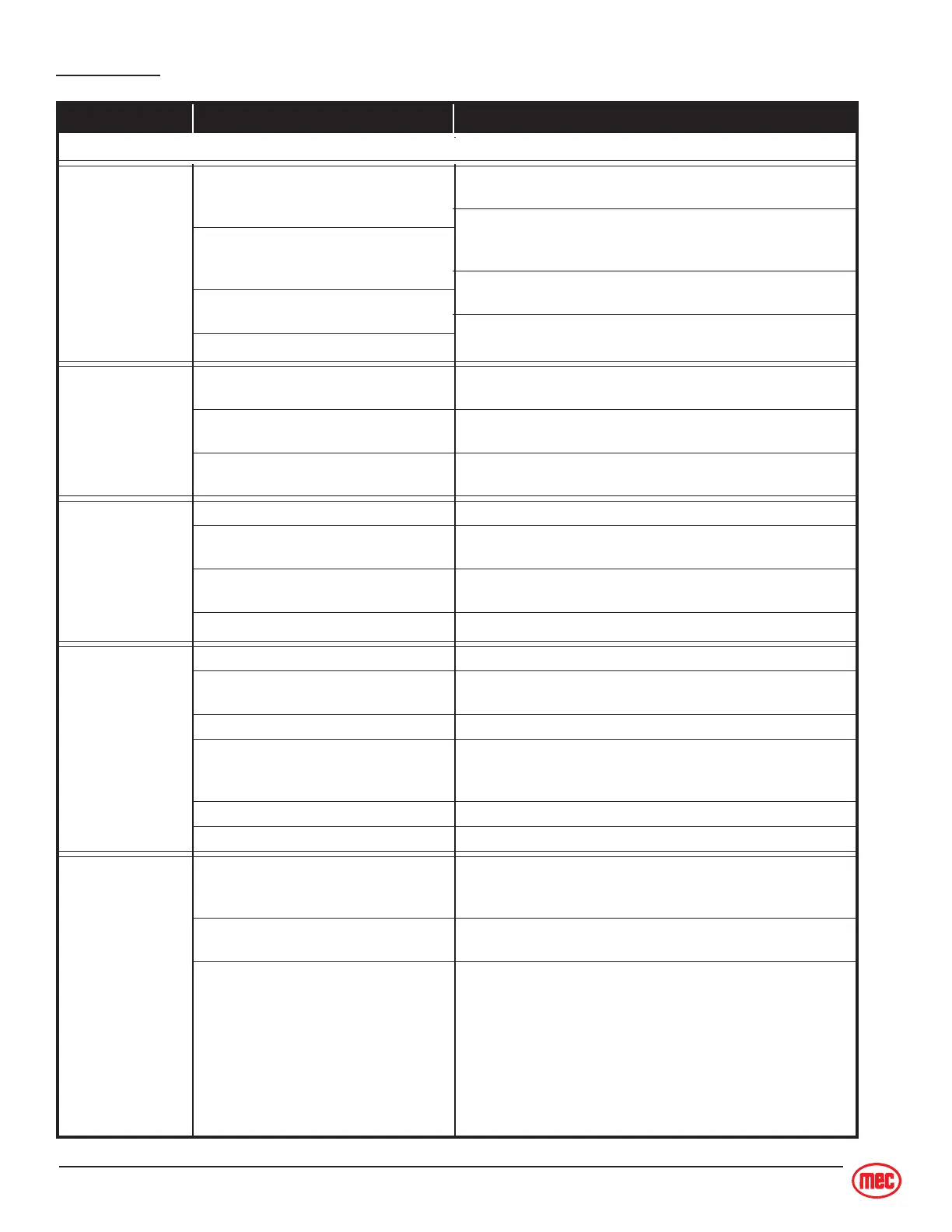

PROBLEM REMEDY/SOLUTIONPOSSIBLE CAUSE

October 2008 "3072ES / 3772ES / 3772ES HD" Service & Parts Manual

Page 4-32

Drive

No drive function 1 or more outriggers deployed partially or

fully

(outrigger equipped models only)

Outrigger switch/s inoperative

Drive valve not shifting

Drive system shut down or interrupted

Check for GREEN LED on upper control box

Operate outrigger retract switch until electric automatically turns off

Check enable light on platform control box

Check outrigger switches located on top of each outrigger jack

Check switch inputs using EZ-Cal (EZ-Cal ID# 2d7 – 2d10)

Check connections at valve

Check drive valve for contamination

Check HELP and MODE message on EZ-Cal

No drive elevated

Slow drive with

Platform stowed

Drive in one direction

only

continued…

Unit out of level

Low battery Voltage

System Interuption

Alarm will sound

Lower and reposition the machine.

Check battery voltage with multi-meter or EZ-Cal.

Clean, service, charge batteries.

Check HELP and MODE message on EZ-Cal

High torque enabled

Limit switch not functioning

Malfunctioning rear wheel bypass valve

Wheel motors not functioning correctly

Check Speed/Torque switch on platform controls

Check limit switch located on left rear of base

Check limit switch input with EZ-Cal (EZ-Cal ID# 2d5)

Located on rear wheels only

Check by replacing valves.

Inspect wheel motors for excessive bypass.

Poor gradability

performance

High or mid speed enabled

Batteries discharged

Wheel motors not functioning correctly

Malfunctioning rear wheel bypass valve

Malfunctioning series parallel valves

Worn hydraulic pump

Check Speed/Torque switch on platform controls

Check battery voltage with multi-meter or EZ-Cal.

Clean, service, charge batteries.

Inspect wheel motors for excessive bypass.

Located on rear wheels only

Check electrical by disconnecting valves.

Check function by replacing valves.

Located on top of main hydraulic manifold

Check with flow meter or replace pump.

Drive valve SVD1 not energized in one

direction

Counterbalance valve CBV1 or CBV2 not

functioning correctly

No output from GP400

Check 12 volts to appropriate coil

Check coil

Check valve function

Swap counterbalance valves to see if functioning direction changes.

Scan using EZ-Cal and troubleshooting charts

EZ-Cal chart ID# 4f-7 – FWD or 2f-9 – Reverse

TROUBLE

Table

continued

Loading...

Loading...