233

CHAPTER 5 DEVICES

5

5.2 Internal User Devices

5.2.6 Annunciator (F)

5.2.6 Annunciator (F)

The annunciator (F) is an internal relay which can be effectively used in fault detection programs for user-created

system. Whenever an annunciator is turned on, SM62 turns on and the anuunciator number is stored in SD62 to

SD79. By monitoring SD62 to SD79, the system can be checked for error and failure.

When F5 is turned on, the corresponding annunciator number is output to the outside.

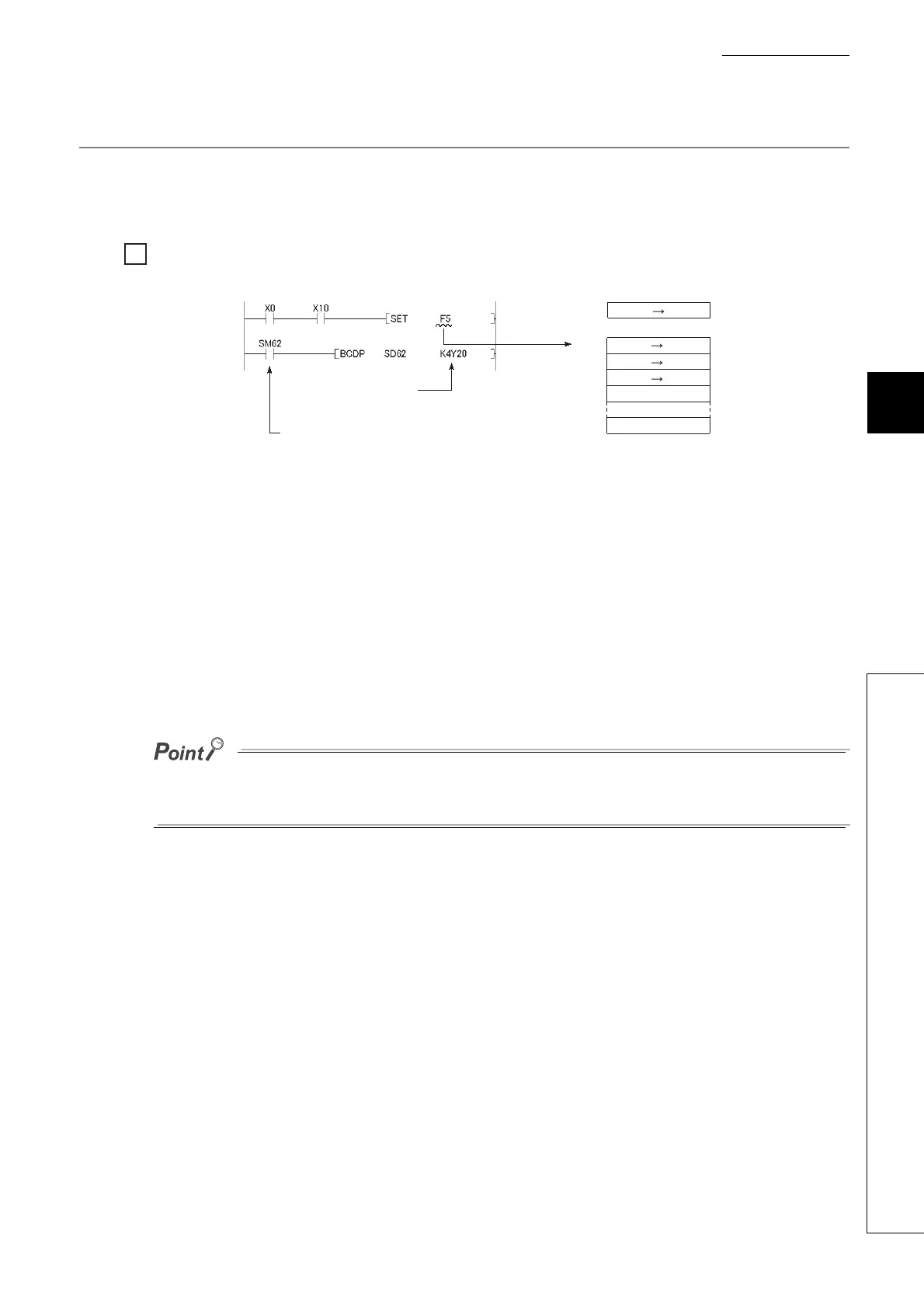

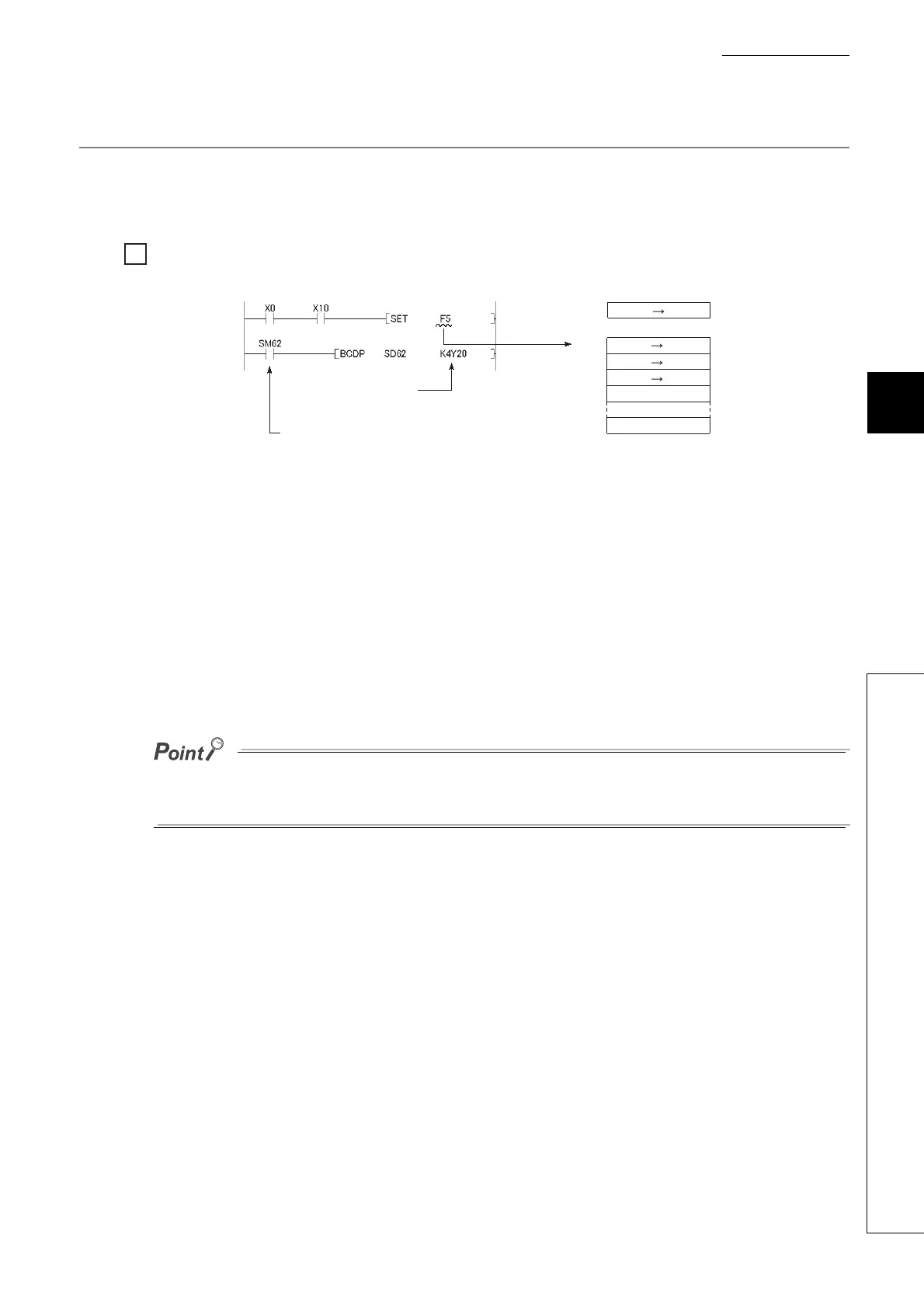

(1) Turning on the annunciator

Use either of the following instructions.

(a) SET F instruction

Annunciator turns on only on the leading edge of an input condition. Even if the input condition turns off, the

annunciator is held on. Using many annunciator numbers can shorten scan time more than using the OUT F

instruction.

(b) OUT F instruction

Since the processing is performed for every scan, the scan time is longer than the case of using the SET F

instruction.

If the annunciator is turned on with any instruction other than SET F and OUT F (for example, the MOV instruction), the

same operation as the internal relay (M) is performed. The ON information is not stored in SM62, and annunciator numbers

are not stored in SD62 and SD64 to SD79.

Ex.

Ex.

SM62

SD62

SD63

SD64

SD65

SD79

0

0

[Fault detection program]

Outputs number of

the annunciator that turned on.

Annunciator ON detection

OFF ON

0 5

0 1

0 5

Loading...

Loading...