272

5.9.2 Common pointer

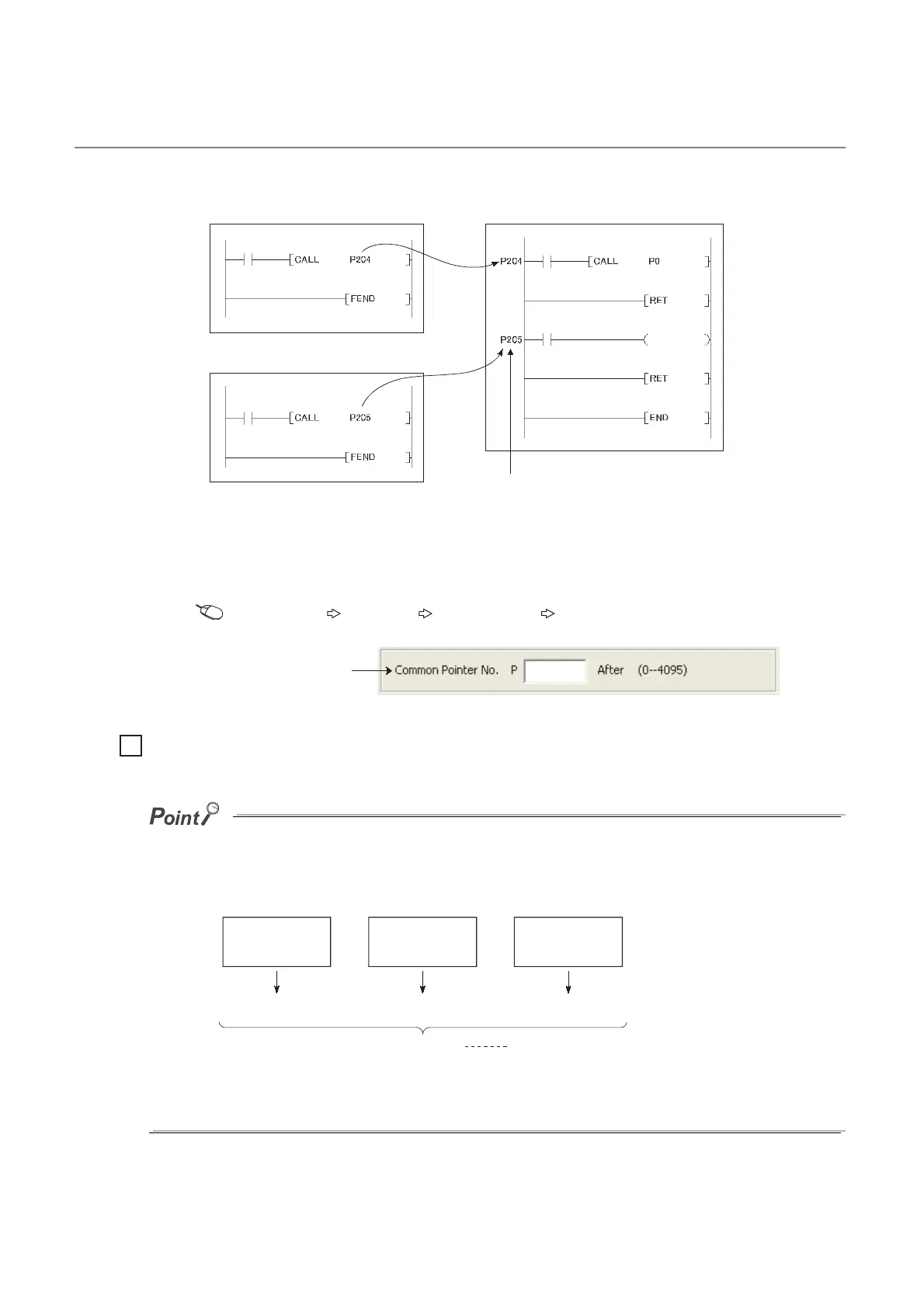

The common pointer is used to call subroutine programs from all programs that are being executed.

To set the common pointer range, enter the start number of the common pointer. The common pointer range is from

the specified pointer number to P4095. However, the pointer number that can be entered here is a number greater

than the total points used for the local pointer.

Project window [Parameter] [PLC Parameter] [PLC System]

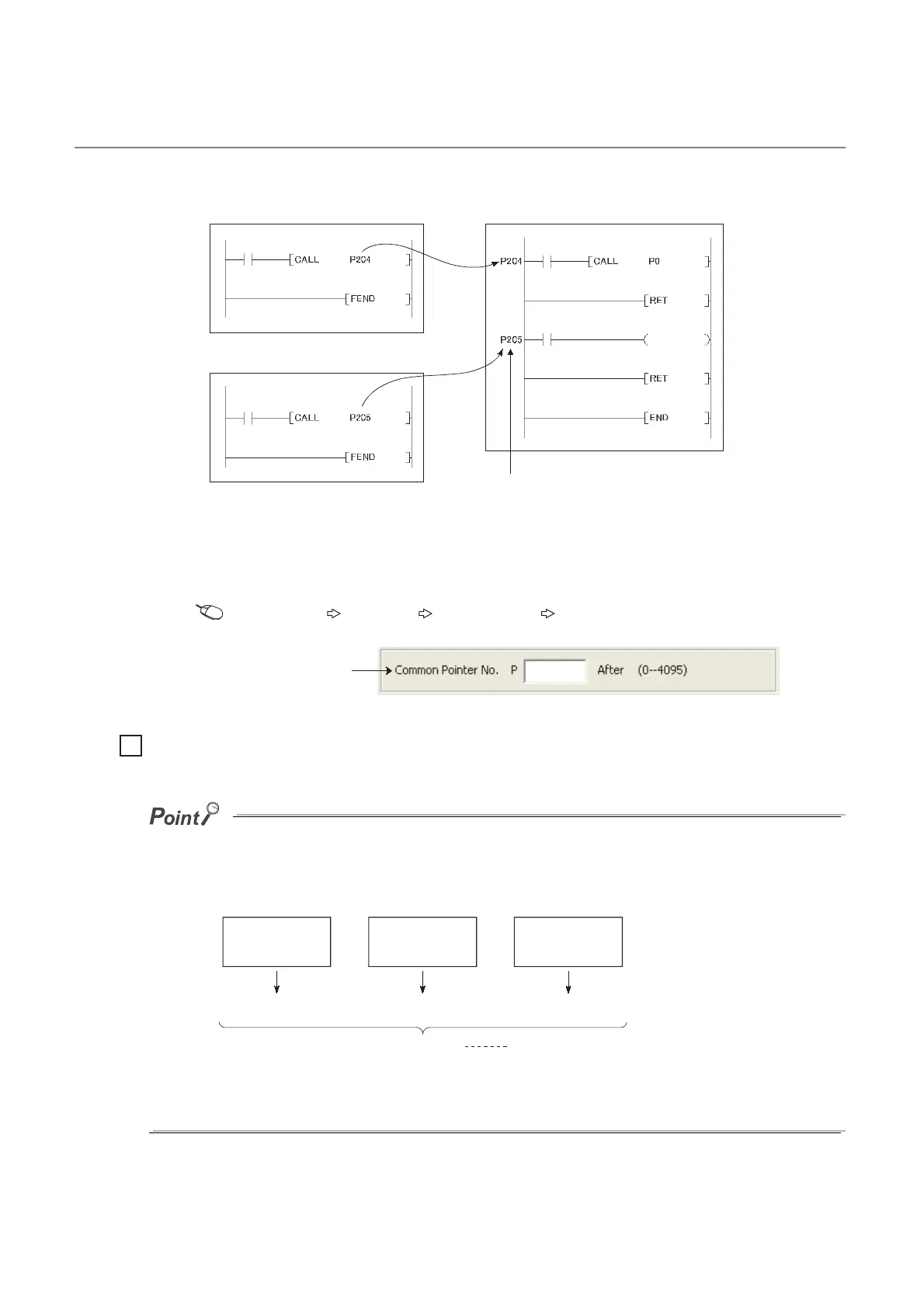

If a total of 400 points are used in three programs (100 points in each of Program A and Program B, and 200

points in Program C), for example, P400 and higher numbers can be set for the common pointer.

● The same pointer number cannot be used as a label. If used, "CAN'T SET(P)" (error code: 4021) occurs.

● If the total number of the local pointer points used in several programs exceeds the start number of the common pointer,

a "CAN'T SET (P)" (error code: 4020) occurs.

● The jump instructions are not capable of executing a jump to the common pointer in other programs. Use the common

pointer with subroutine call instructions only.

Program A Program C

Program B

Label

Set the start number for

the common pointer.

Ex.

Ex.

100 points of P0 to

P99 occupied

100 points of P0 to

P99 occupied

200 points of P0 to

P199 occupied

Program A Program B Program C

Total of 400 points

are used.

Using P0 to P99 Using P0 to P99 Using P0 to P199

P400 and higher numbers can be

used for the common pointer.

Loading...

Loading...