108

3.13.2 Remote PAUSE

This operation externally changes the operating status of the CPU module to PAUSE, keeping the CPU module switch

in the RUN position.

PAUSE status is a status where program operations in the CPU module are stopped, holding the status (on or off) of all

outputs (Y).

This operation is useful, especially during the process control, to hold the on status of outputs (Y) even after the

operating status of the CPU module is switched from RUN to STOP.

(1) Executing method

There are three methods for performing the remote PAUSE operation.

• Using a PAUSE contact

• Using a programming tool

• By an external device using the MC protocol

(a) Using a PAUSE contact

Set a PAUSE contact.

Project window [Parameter] [PLC Parameter] [PLC System]

When setting a PAUSE contact, set a RUN contact as well. (Setting of only a PAUSE contact is not allowed.)

Set a device used as a contact.

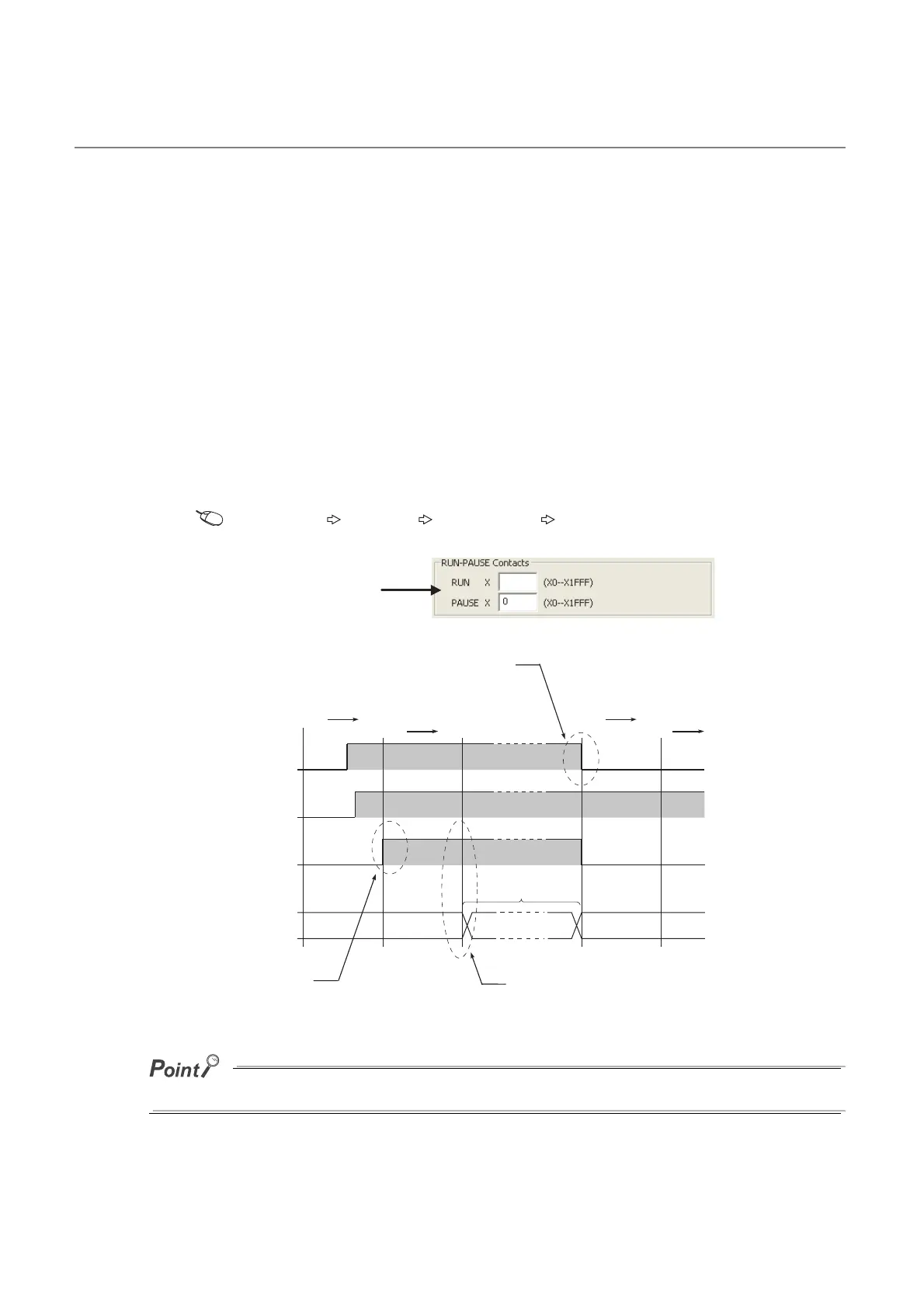

OFF

ON

0 END

PAUSE status

0 END

0

0

END END

PAUSE enable coil (SM206)

OFF

ON

PAUSE contact (SM204)

OFF

ON

RUN/PAUSE status

RUN

RUN

PAUSE

Turns on at execution of the END

processing in the scan where set

PAUSE contact and SM206 turn on.

The CPU module enters the PAUSE status and

stops operation when an operation is processed up

to the END instruction in the scan next to the one

where the PAUSE contact turns on.

Turning off the PAUSE contact or SM206 will

exit the PAUSE status and restart program

operation from step 0.

Set PAUSE contact

Loading...

Loading...