258

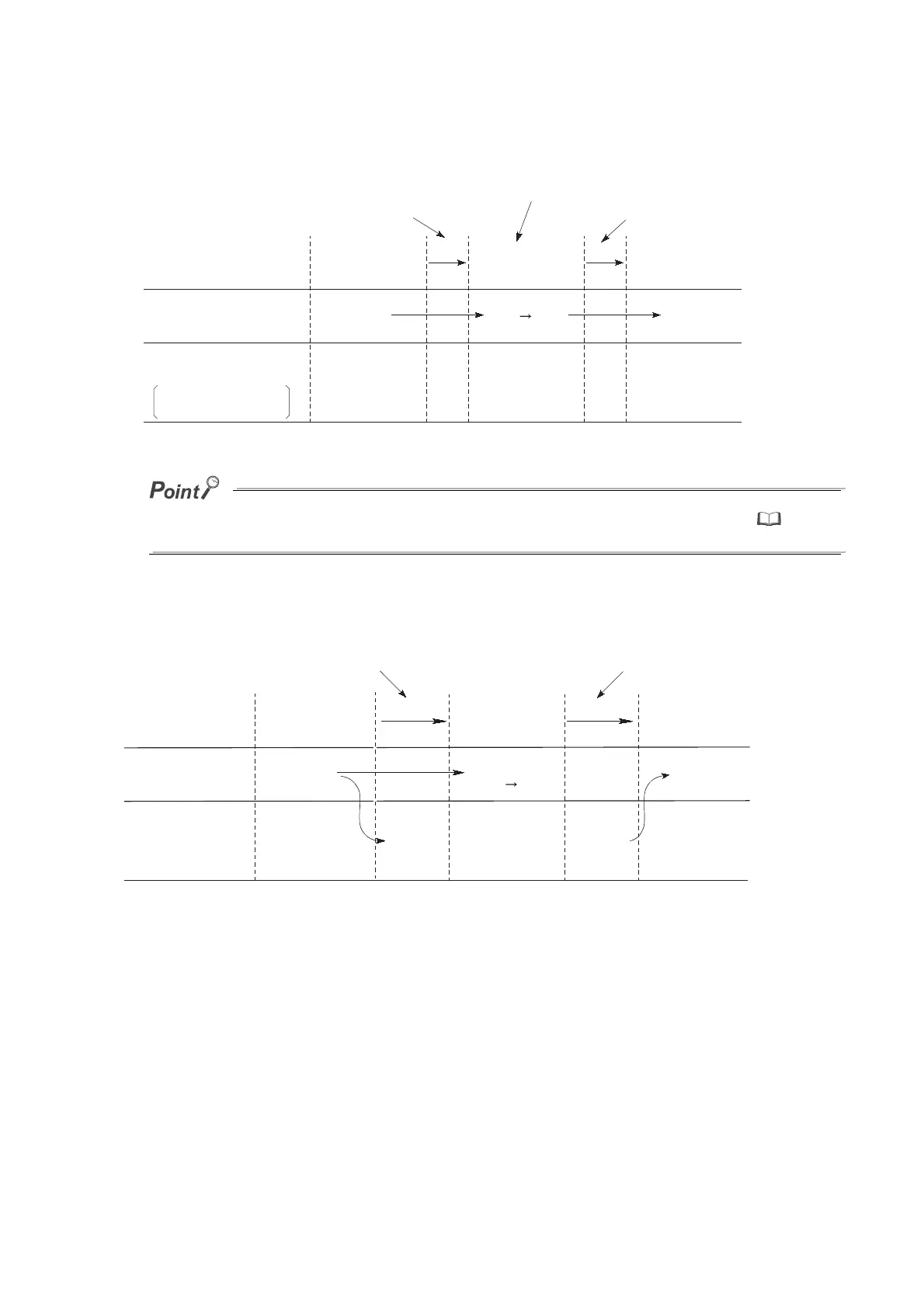

(b) When "High Speed Execution" is selected

*1 The Z0 value is changed to 3 in the interrupt program.

When writing data to the index register, use the ZPUSH or ZPOP instruction to save and restore the data. ( MELSEC-

Q/L Programming Manual (Common Instruction))

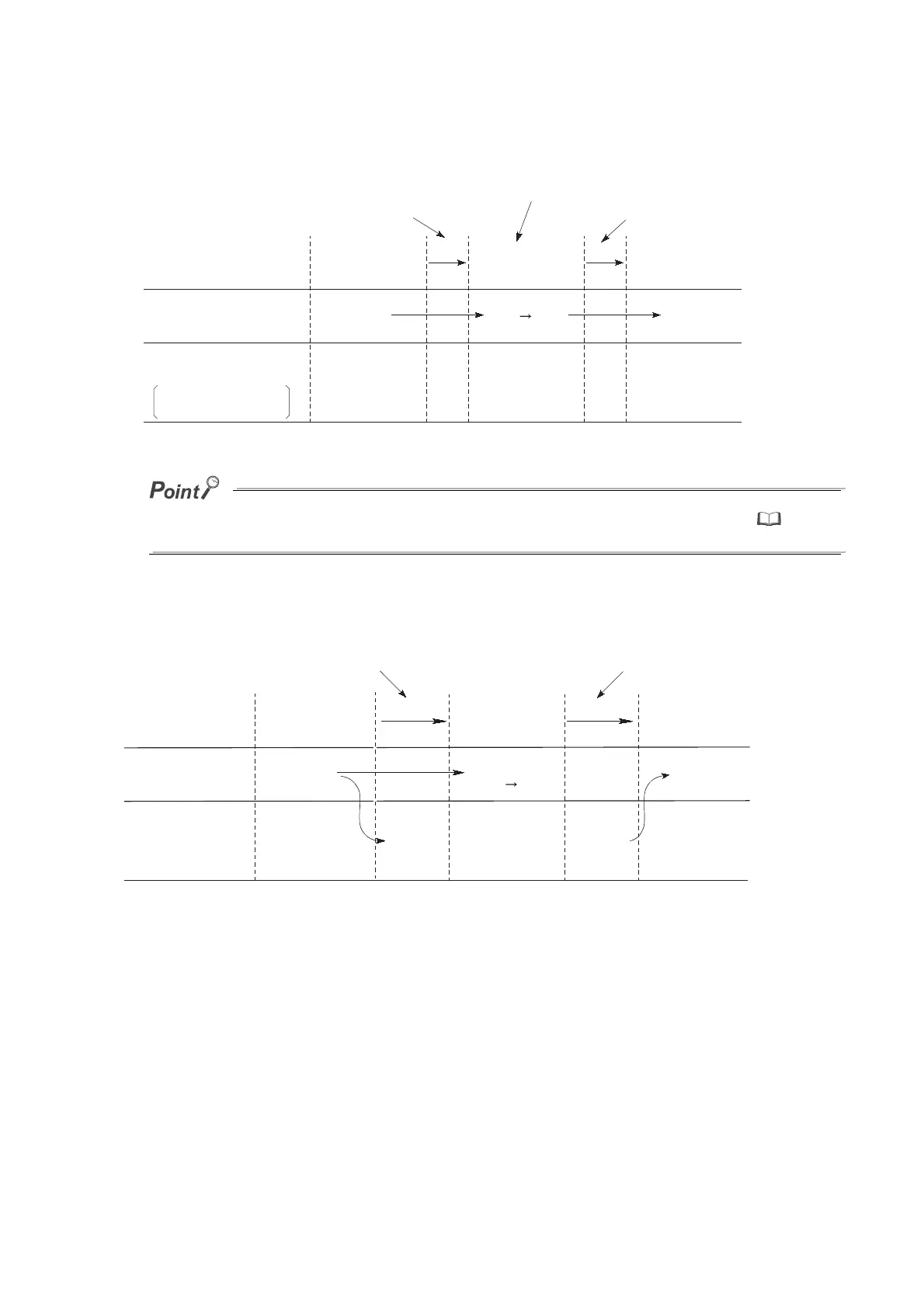

(3) Processing of file register block numbers

Execution program

Z0 = 1

Z0 = 0

Switching Restored

Passed Passed

Z0 = 0 Z0 = 0 Z0 = 0 Z0 = 0

Z0 = 3

Index register value

Save area of index register

for scan execution

type program

Scan execution

type program

Interrupt/fixed

scan execution

type program

Scan execution

type program

1) The CPU module does not save index register

values at program switching.

2) If data are written to the index register, the values of

the index register used in the scan execution type program

will be corrupted at program switching.

Z0 = 1 Z0 = 3

*

1

3) The index register

values are not saved.

[RSET K0]

Execution program

Save area

Switching

Restored

Block 1

Restored

Block 1Block 1Block 1 Block 1Block 0

Block 1

Passed

Saved

Block 1 0

Block No. of

file register

Scan execution

type program

Scan execution

type program

Interrupt/fixed

scan execution

type program

1) The CPU module saves the block numbers of

the file register and passes them at program

switching.

2) The CPU module restores the block

numbers of the file register saved at

program switching.

Loading...

Loading...