61

CHAPTER 2 APPLICATION OF PROGRAMMING

2

2.8 Executing Multiple Programs

2.8.1 Initial execution type program

(2) Initial scan time

Initial scan time is the execution time of initial execution type program. When multiple programs are executed, the

initial scan time will be the time required for completing all the initial execution type program execution.

Since the CPU module stores the initial scan time into the special register (SD522 and SD523), the initial scan

time can be checked by monitoring SD522 and SD523. (Accuracy: ±0.1ms)

If the stored values in SD522 and SD523 are 3 and 400 respectively, the initial scan time is 3.4ms

Even if the WDT instruction (instruction that resets the watchdog timer) is executed in the program, the

measurement of the initial scan time continues.

When an interrupt program or fixed scan execution type program is executed before completion of the initial execution type

program execution, the execution time of the executed program will be added to the initial scan time. When an interrupt

program of fixed scan execution type program is executed before completion of the initial execution type program execution,

the execution time of the executed program will be added to the initial scan time.

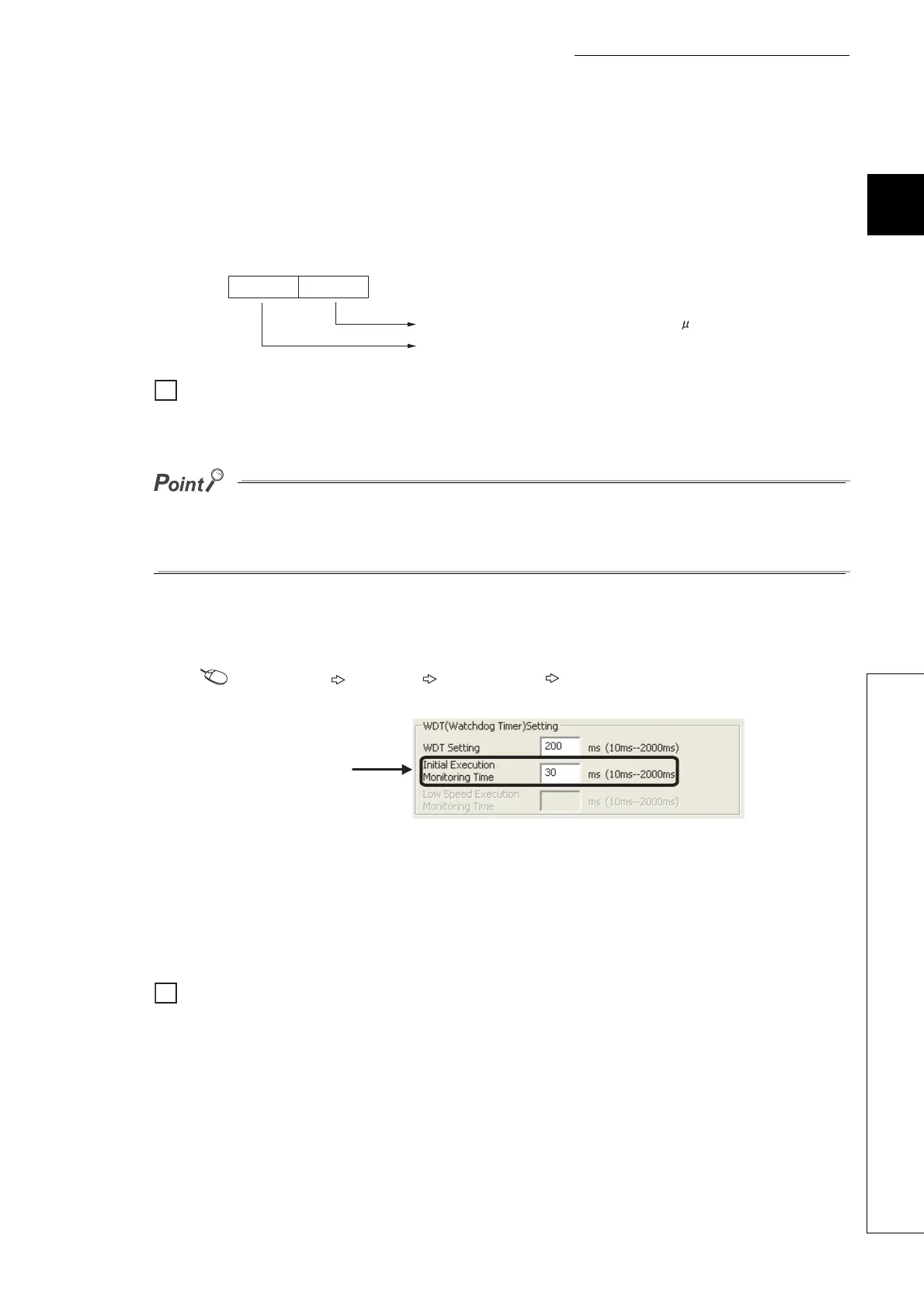

(3) Initial execution monitoring time

Initial execution monitoring time is a timer for monitoring initial scan time.

Project window [Parameter] [PLC Parameter] [PLC RAS]

The setting range is 10 to 2000ms (in increments of 10ms). No default value is set.

(4) Precautions on programming

Initial execution type programs do not support the instructions that require several scans (instructions with

completion device).

SEND, RECV and similar instructions

SD522 SD523

Stores the initial scan time of 1ms or less (unit: s)

Stores the initial scan time. (in increments of 1ms)

Ex.

Ex.

Set initial execution

monitoring time.

Ex.

Ex.

Loading...

Loading...