SECTION 6: T200 FUNCTIONAL OVERVIEW T200 User's Manual

PAGE 6-7

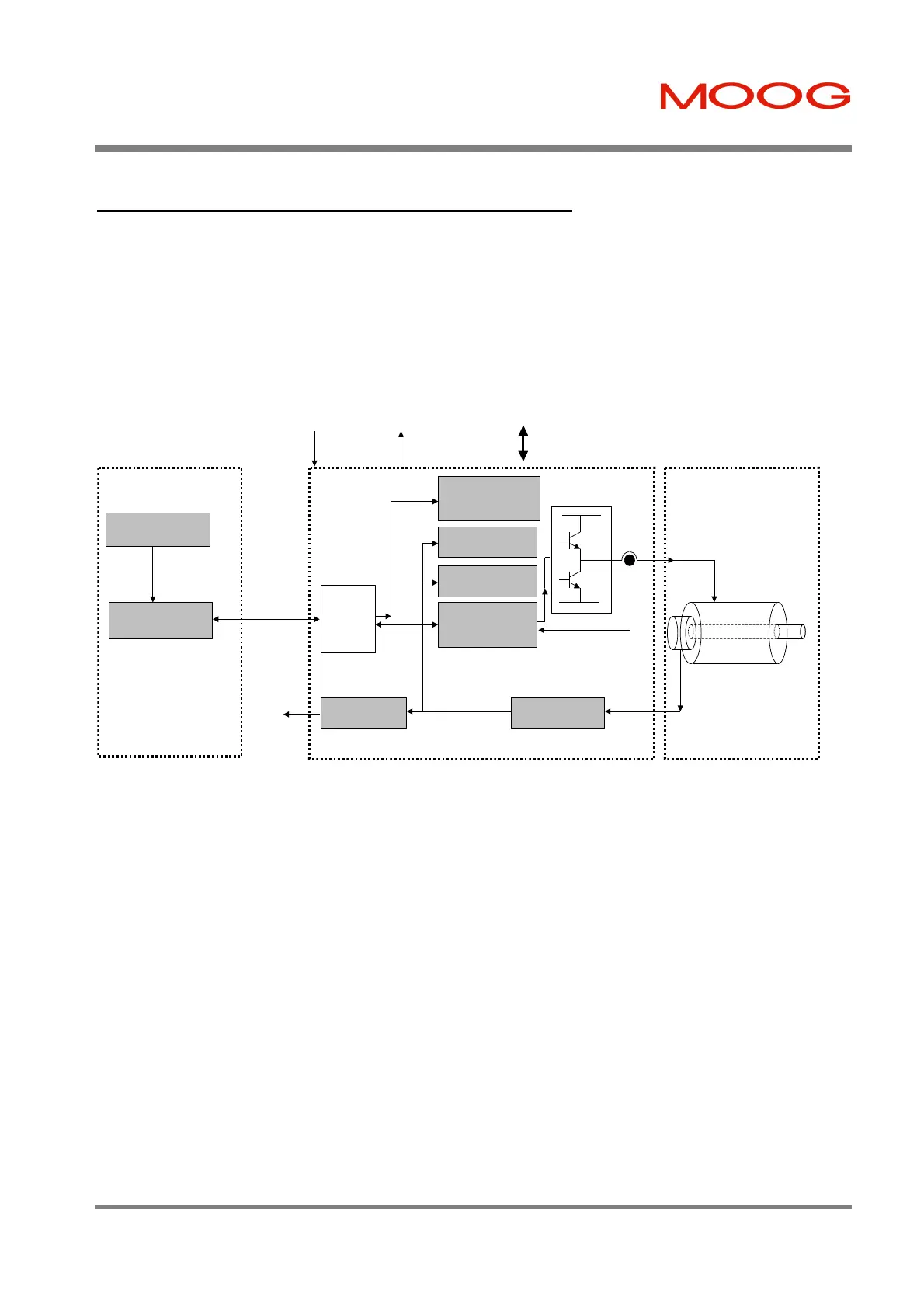

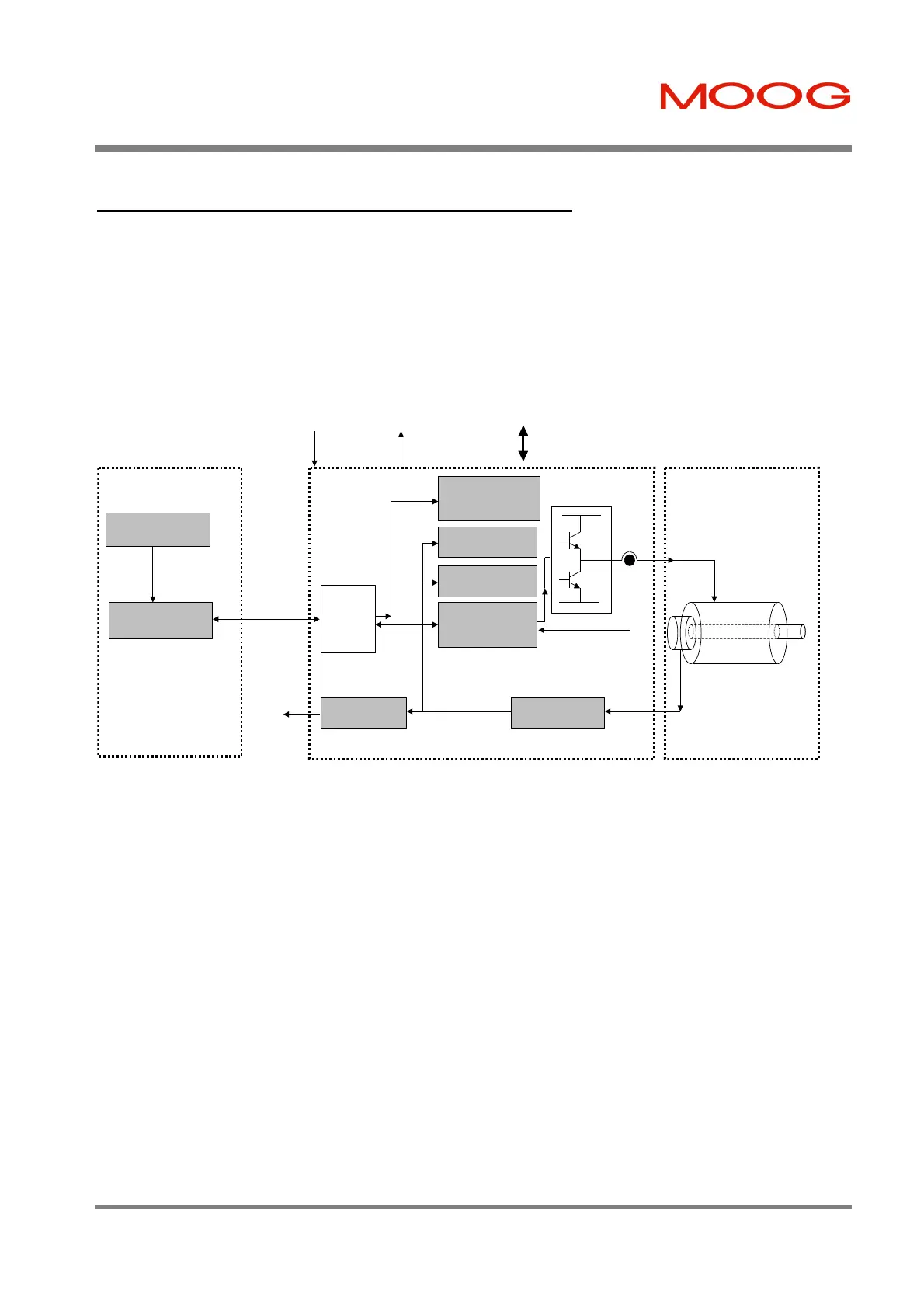

6.2.2 Controller Area Network (CAN) Interface Mode

The T200 provides a CAN fieldbus connection. The CAN interface provides:-

• Set-up of all drive parameters using a standard communications protocol (CANOpen).

• High-speed transfer of process and status information. This removes the need for extensive interconnect between

the T200 and the System Motion Controller.

Velocity Control

Position Control

Vector-Controlled

Torque/Current

Loops

Resolver

Position

Motor

Resolver to Digital

System Motion

Controller

Position Command

Generation

CAN Interface

CAN

Interface

Function

RS232 / RS485

Moog T200

Moog Motor

Actual

Motor

Position

CAN Cable

Position Interpolation

and Trajectory

Generator Function

Control Signalling (to/from

Machine Safety and Indication I/O)

ENABLE

PWR_RDY

AUTO_MAN

CW_LIM

CCW_LIM

BRK_IP (tied high)

HOME THRM_LIM

Q-STOP DRV_ENBLD

Figure 6.2:- CAN Interface Mode System Diagram

Note that the ENABLE, PWR_RDY and AUTO_MAN inputs are used consistently for all control modes.

• Each T200 has network node identification switches provided on their front panel, such that each node may be

addressed uniquely via the CAN interface

• Motor configuration, control modes, control loop gains and other parameterisation information can be read from and

written to the T200. Extensive diagnostic information and fault history data can also be read back and analysed by

the System Motion Controller. Data sequences can be logged using complex trigger conditions and transmitted

back to the System Motion Controller.

• The T200 provides several positioning and velocity modes when operated via the CAN interface:-

1. Interpolation Mode. The System Motion Controller transmits target positions at high data rates, and the T200

finely interpolates these positions to follow the target trajectory.

2. Point to Point Mode. The System Motion Controller transmits a target position, velocity and acceleration via

the CAN interface. The T200 generates a smooth trajectory to the target position using this data.

3. Gearing Mode. A 'master' T200 generates a 'Master-Angle' position reference at a high rate. One or many

T200 'slaves' receive this reference. These slaves multiple the 'Master-Angle' by a user programmed factor,

and use the result as their command position.

4. Camming Mode. Slave T200's simulate a mechanical cam with high precision. Slave T200's transform the

'Master-Angle' through a user defined cam shape, and use the result as their command position.

5. Velocity Mode. The T200 operates in velocity mode, with the command velocity and torque limit transmitted at

high speed via the CAN interface.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...