T200 User's Manual SECTION 8: HAND-HELD-TERMINAL INTERFACE

PAGE 8-8

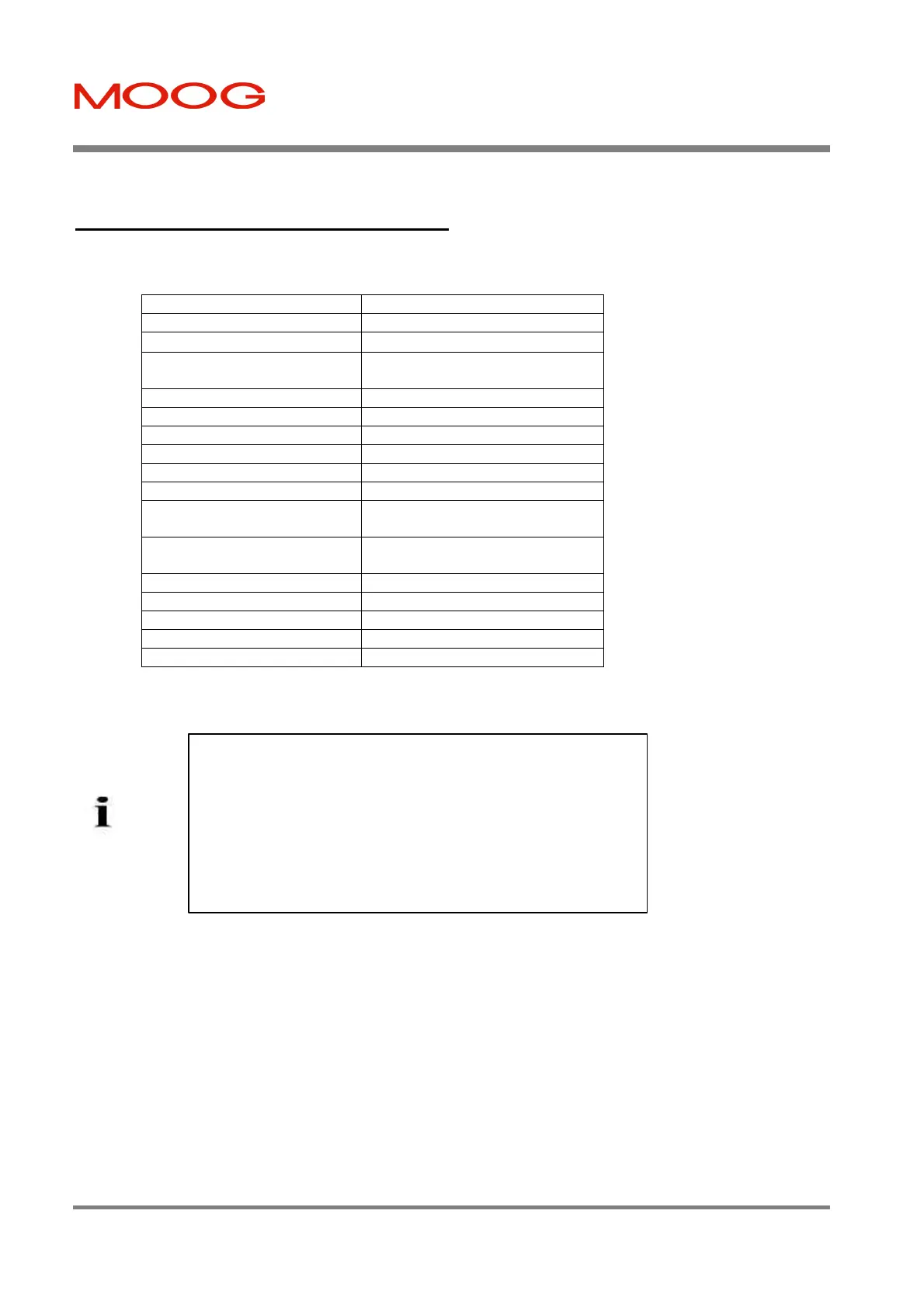

8.2.3 Non-Standard Motor Configuration

Applications employing non-standard motor models (other than the G4XX series) require the data listed in Table 8.1

PARAMETER UNITS

Torque Constant (Kt) Nm/Ar.m.s. or Nm/Aeff

Stator Resistance (Rtt)

Ohms (Ω)

Quadrature Axis Motor

Inductance

Millihenries (mH)

Direct Axis Motor Inductance Millihenries (mH)

Nominal Motor Speed RPM

Maximum Motor Speed RPM

Peak Rated Motor Current Ar.m.s. or Apeak

Current Loop Gain 0 to 15

Number of Motor Poles Usually 8 or 12 for Moog motors

Rated Continuous Motor Ø

Current (Ic)

Ar.m.s. or Apeak

Rated Peak Motor Ø

Current (Ip)

Ar.m.s. or Apeak

Motor Nominal Speed RPM

Current Loop Gain 0 to 15

Motor Observer Inertia (Jm) kg-cm

2

Resolver Pole Pairs Usually 2 for Moog motors

Motor Thermistor True or False

Table 8.1:- Non-Standard Motor Parameter Set

To configure for a non-standard motor, proceed with drive initialization as outlined previously. Use the [SNM]

command. Enter the non-standard motor model number when prompted for the motor model number. After confirming

the model number entered, the servo-drive will recognize a non-standard motor model number and prompt for entry of

the motor parameters listed above.

- The following conversions are useful for motor parameters:

Kt (Nm/ Ar.m.s.) = .113 * Kt (lb-in/Ar.m.s.)

Ic (Ar.m.s.) = Tc (Nm) / Kt (Nm/Ar.m.s.)

Ip (Ar.m.s.) = Tp (Nm) / Kt (Nm/Ar.m.s.)

where:

Ic = Rated Continuous Motor Phase Current

Tc = Rated Continuous Motor Torque

Ip = Rated Peak Motor Phase Current

Tp = Rated Peak Motor Torque

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...