MTC-160

REFRIGERANT LINES

Revision: January 2005 2004 Quest

4. Start the engine and switch the A/C system ON.

5. When the A/C system is operating (compressor running), inject one bottle 7.4 cc (1/4 ounce) of HFC-134a

(R-134a) fluorescent leak detection dye (J-41447) through the low-pressure service valve using HFC-

134a (R-134a) dye injector (J-41459). Refer to the manufacturer's operating instructions.

6. With the engine still running, disconnect the HFC-134a (R-134a) dye injector (J-41459) from the low-pres-

sure service valve.

7. Operate the A/C system for a minimum of 20 minutes to mix the HFC-134a (R-134a) fluorescent leak

detection dye (J-41447) with the A/C system oil. Depending on the leak size, operating conditions and

location of the leak, it may take from minutes to days for the HFC-134a (R-134a) fluorescent leak detec-

tion dye to penetrate an A/C system leak and become visible.

Electronic Refrigerant Leak Detector EJS001TW

PRECAUTIONS FOR HANDLING LEAK DETECTOR

NOTE:

When performing a refrigerant leak check, use a electronic refrigerant leak detector (J-41995) or equivalent.

Ensure that the electronic refrigerant leak detector (J-41995) is calibrated and set properly according to the

manufacturer's operating instructions.

The electronic refrigerant leak detector (J-41995) is a delicate

device. To use the leak detector properly, read the manufacturer's

operating instructions and perform any specified maintenance.

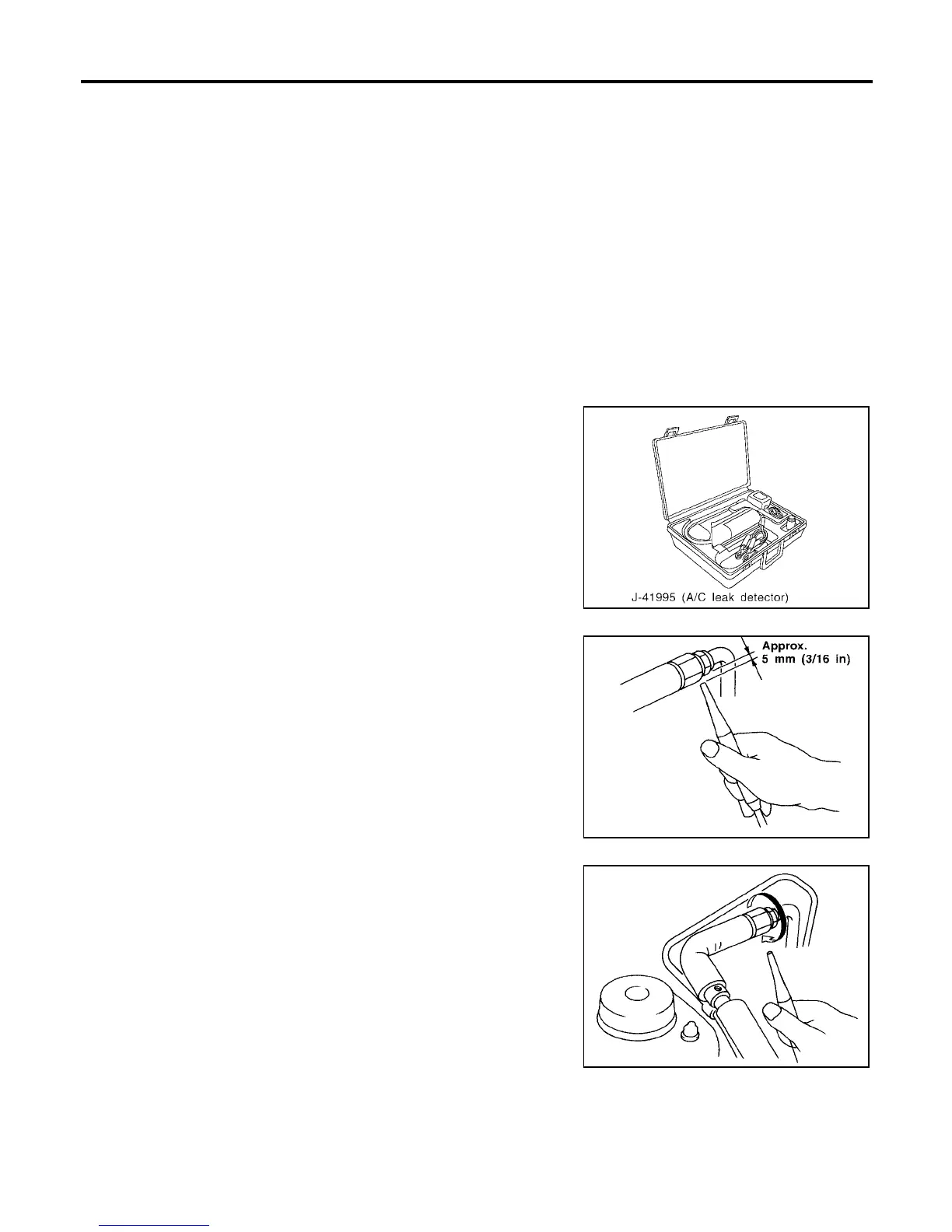

1. Position the probe approximately 5 mm (3/16 in) away from the

point to be checked as shown.

2. When checking for leaks, circle each fitting completely with the

probe as shown.

SHA196FA

SHA707EA

SHA706E

Loading...

Loading...