REFRIGERANT LINES

MTC-161

C

D

E

F

G

H

I

K

L

M

A

B

MTC

Revision: January 2005 2004 Quest

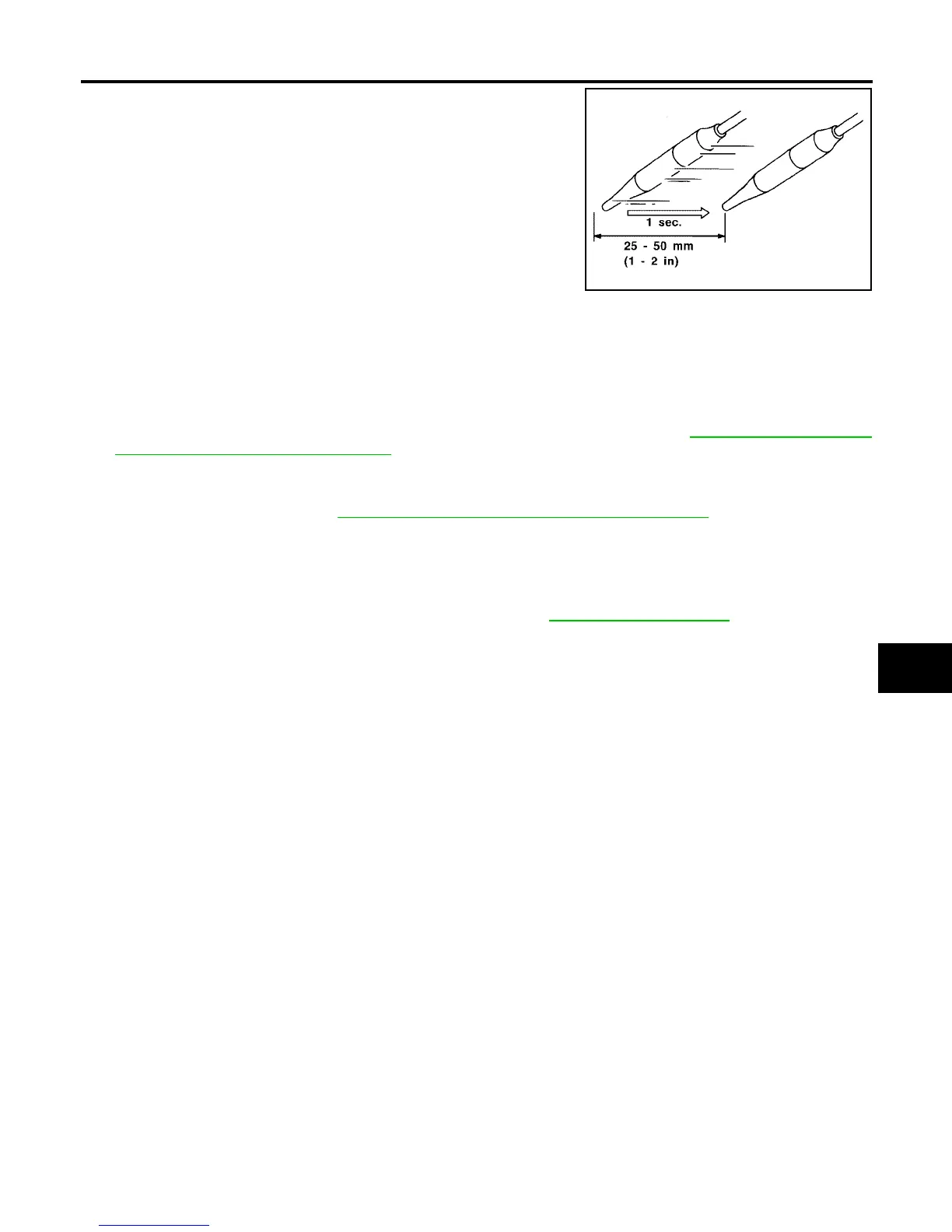

3. Move the probe along each component at a speed of approxi-

mately 25 - 50 mm (1 - 2 in)/second as shown.

CHECKING PROCEDURE

NOTE:

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in a calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn the engine OFF.

2. Connect the manifold gauge set (J-39183-C) to the A/C service ports. Refer to MTC-144, "

SETTING OF

SERVICE TOOLS AND EQUIPMENT" .

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.52 kg/cm

2

, 50 psi) above a temperature of

16°C (61°F). If less than specification, recover/evacuate and recharge the system with the specified

amount of refrigerant. Refer to MTC-144, "

HFC-134a (R-134a) Service Procedure" .

NOTE:

At temperatures below 16°C (61°F), leaks may not be detected since the system may not reach 345 kPa

(3.52 kg/cm

2

, 50 psi) pressure.

4. Conduct the leak test from the high pressure side (compressor discharge to evaporator inlet) to the low

pressure side (evaporator drain hose to shaft seal). Refer to MTC-146, "

Components" . Clean the compo-

nent to be checked and carefully move the electronic refrigerant leak detector probe completely around

the following connections and components.

● Compressor

● High and low-pressure pipe and hose fittings, relief valve, and compressor shaft seal

● Liquid tank

● Refrigerant pressure sensor

● Service valves. Check all around the service valves. Ensure service valve caps are secured on the ser-

vice valves (to prevent leaks).

NOTE:

After removing manifold gauge set (J-39183-C) from the service valves, wipe any residue from the ser-

vice valves to prevent any false readings by the electronic refrigerant leak detector (J-41995).

● Evaporator

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in

the heater and cooling unit assembly. Wait a minimum of 10 minutes accumulation time (refer to the

manufacturer's recommended procedure for actual wait time) before inserting the electronic refrigerant

leak detector probe into the heater and cooling unit assembly drain hose.

NOTE:

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with

water or dirt that may be in the drain hose.

5. If a leak is detected, verify at least once by blowing compressed air into the area of the suspected leak,

then repeat the leak check.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components and

connections.

7. If no leaks are found, perform steps 8 - 11.

8. Start the engine.

9. Set the heater A/C controls as follows:

SHA708EA

Loading...

Loading...