6.3.4 Current position value setting (I/O address: 16396 [16460])

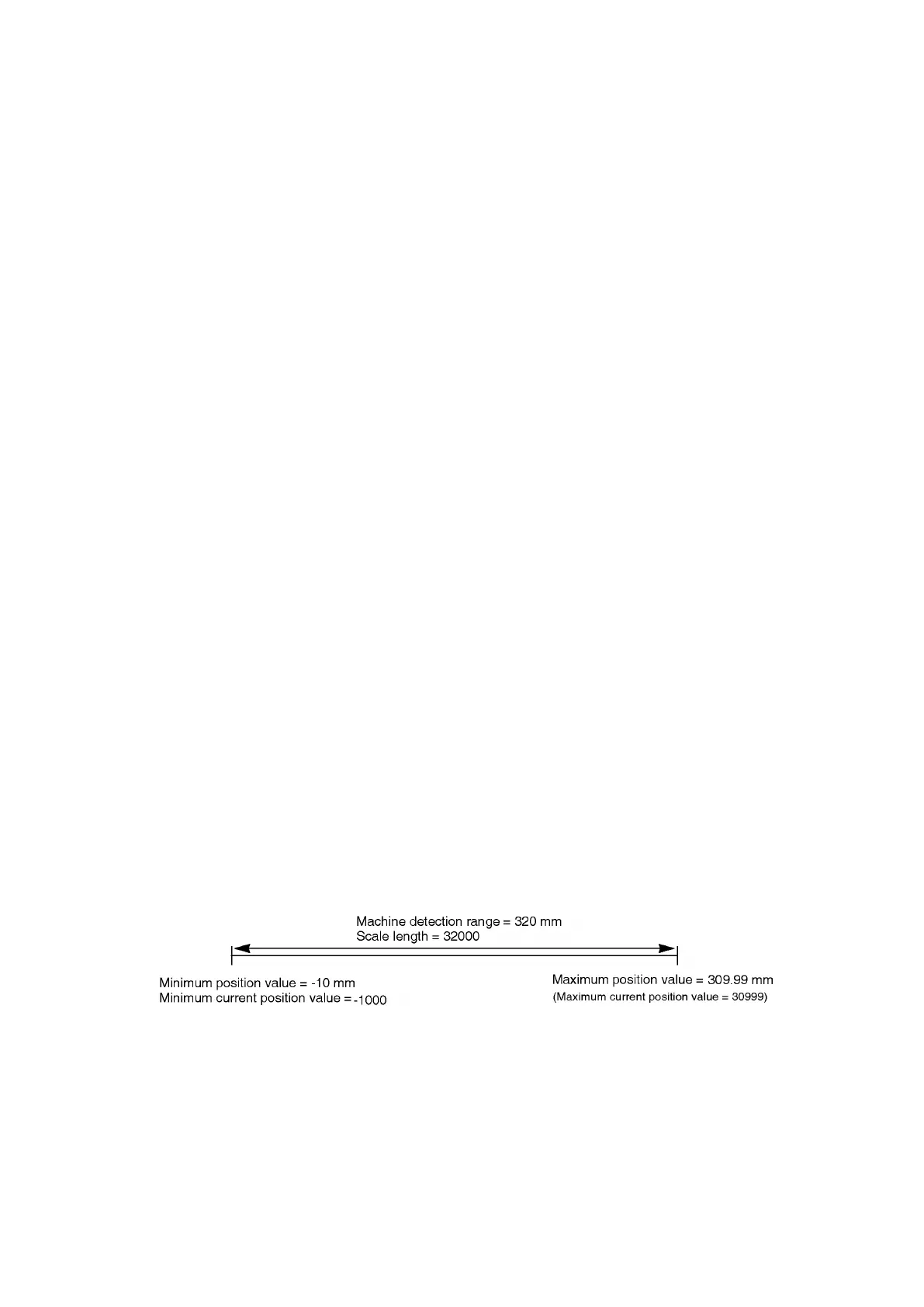

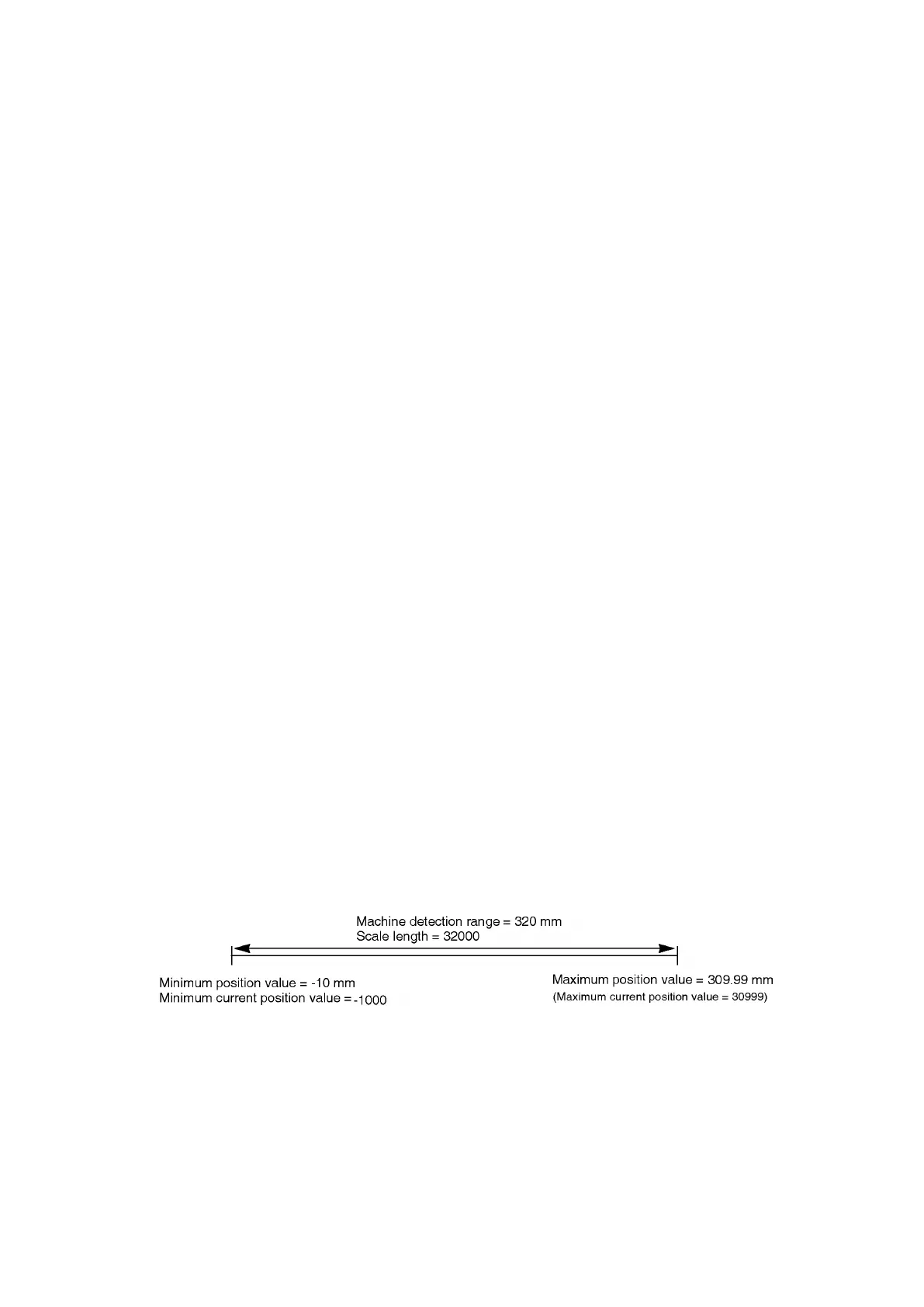

This section explains how to set the current position value. the “current position value” setting consist

of designating a numeric value which corresponds to a given machine position.

For example、if the machine is moved to its 100 mm position (or any desired position), the “current

position” setting which corresponds to that position would be designated as “10000” (when resolution

is 0.01). The “current position” setting provides a reference value on which the detection range

([minimum current position value] to [minimum current position value + scale length – 1]) is based.

Setting sequence:

(a) Move the machine to the desired setting position.

(b) Turn the PLC Ready signal (command 1: 7 bit) OFF.

(c) Set “1” to initial setting and write select bit of I/O address 4 (B1 and B4).

(d) Write the setting value to buffer memory addresses 16396 (16460).

(e) Turn the PLC Ready signal ON.

(f) Writing is completed when operation status (status 1: 7 bit) has turned ON.

Notes:

o Current position settings are executed simultaneously for 2 axes. To designate settings at each

axis individually, use the current position preset function.

o Depending on the minimum unit of current position change (resolution), there may be cases in

which the current position value will vary slightly from the current position setting value. When the

current position value is between the minimum units, the larger value will be selected.

Ex.) Current position value change: 0 → 7 → 15

Current position setting value: 10

Because the current position setting value is between 7 and 15, the larger value of “15” will

be designated as the current position value.

Important:

Current position value setting shall not exceed 10000 times. If exceeding this, use current position

preset function.

CURRENT POSITION VALUE

This value indicates where the machine is currently positioned within the machine detection range.

This can be expressed in two ways: By a sensor binary current position value, or by a scaling binary

current position value.

(a) Sensor binary current position value:

With this format, the machine’s current position within the scale length is detected by the

ABSOCODER sensor, and that position value is expressed as a ‘sensor binary value’.

ABSOCODER sensor detection ranges: 0-131071 (1FFFFHEX)

Loading...

Loading...