Chapter 1. Overview

7

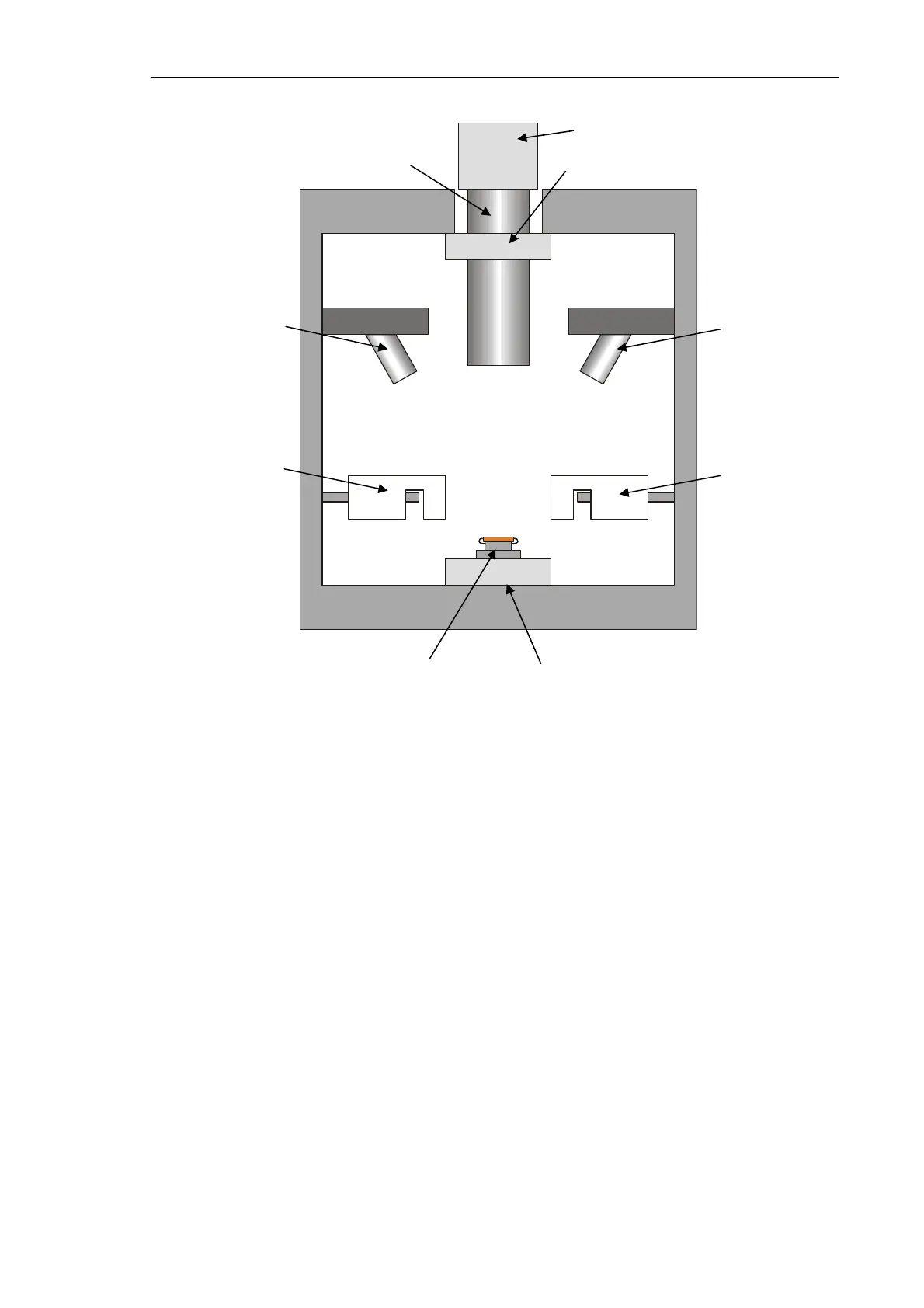

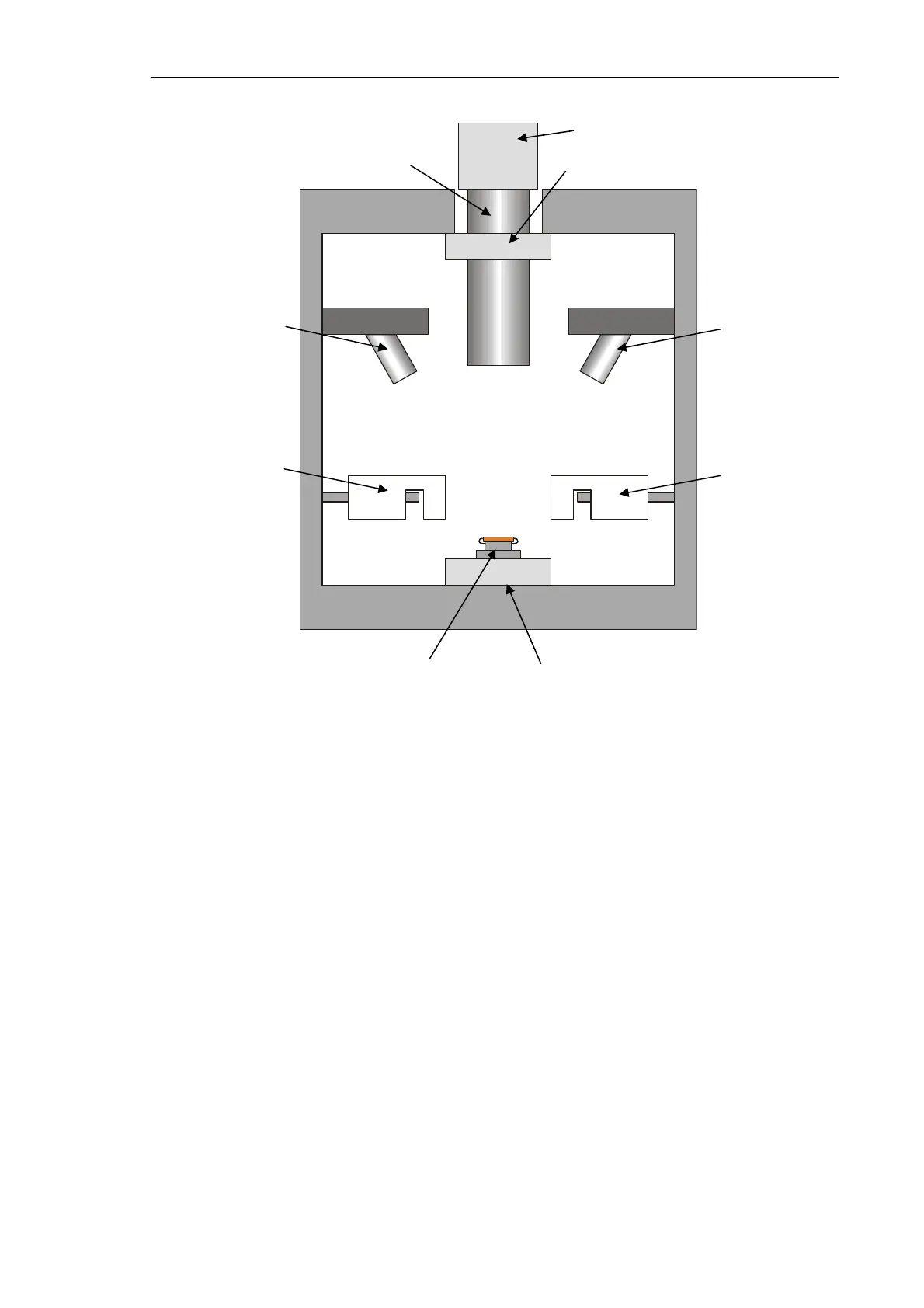

Fig. 1-2. Schematic diagram of the Solver NEXT

The sample to study is fixed on a metal substrate that is mounted on the sample holder. The

sample holder is fastened to the upper end of the piezo scanner that operates in the

“scanning-by-sample” mode.

The positioning system allows moving the sample in the XY plane to select the

investigation area as well as displacing the sample vertically to approach it to the probe.

The built-in optical viewing system serves for selecting the scan area on the sample

surface. The optical microscope of this system is equipped with a positioning system that

provides selection of the scan area on the sample surface.

The Solver NEXT measuring unit is equipped with two measuring heads, for atomic-force

microscopy (AFM) and for scanning tunneling microscopy (STM). Availability of two

built-in measuring heads enables quick exchange of the experimental technique and does

not need special training of the operator.

Auxiliary measuring heads (for liquid environment and for nanoindenting) extend range of

the instrument capabilities. With those heads, measurements in liquids as well as hardness

measurements or modification of the sample surface are available.

Sample

Video camera

Optical microscope

Sample positioning system

Optical microscope

positioning system

Laser

Photodiode

STM measuring

hea

AFM measuring

head

Loading...

Loading...