183

Determining the Error from the Current Situation for Temperature Control Errors

Section 7-6

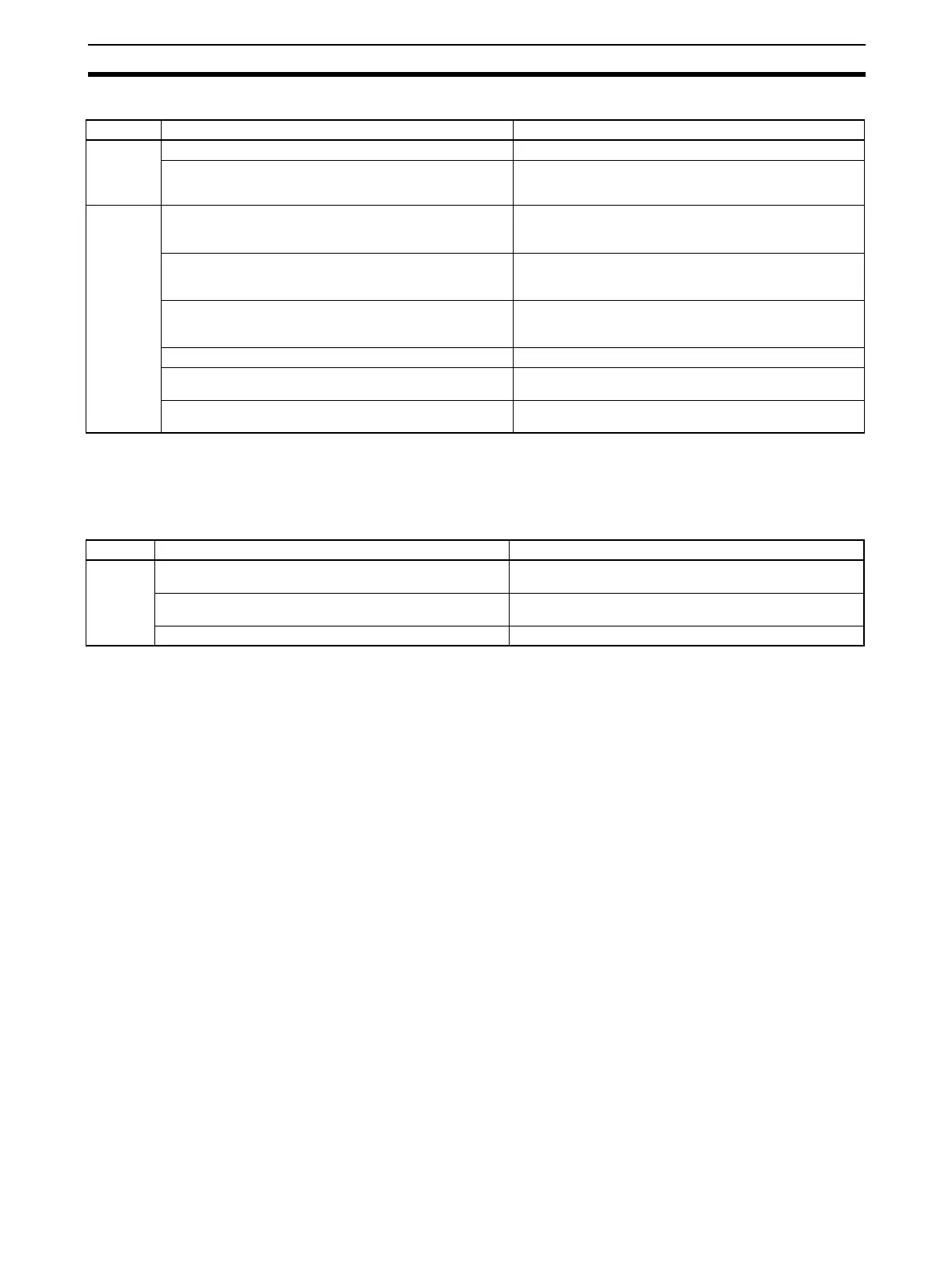

Overshooting or Undershooting

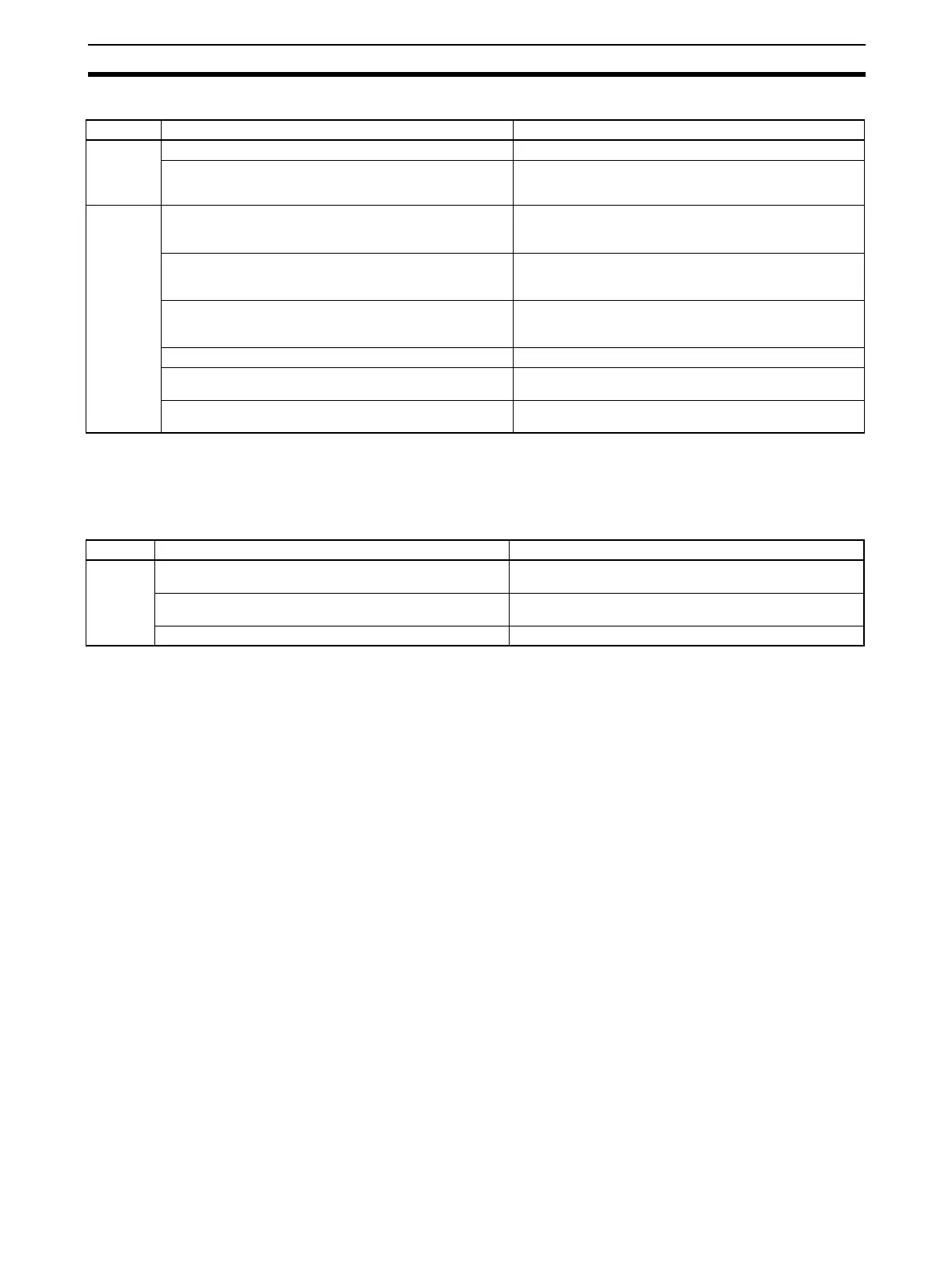

Hunting

The troubleshooting items for connection and setting problems are the same as for overshooting and under-

shooting, above.

Possible cause Countermeasure

Connection Measured temperature is wrong. • Perform the action outlined in 7.5.

A general-purpose thermometer with slow thermal response

has been connected to a control system with fast thermal

response.

• Change to a sheathed thermometer.

Setting The proportional band value is too low. • Increase the proportional band within a range with an

acceptable response delay.

• Execute autotuning (AT).

The integral time is too short. • Increase the integral time within a range with an acceptable

response delay.

• Execute autotuning (AT).

The derivative time is too short. • Increase the derivative time within a range that does not

adversely affect the stability of stabilization time.

• Execute autotuning (AT).

ON/OFF control is operating. • Execute P control or PID control.

The control cycle is too long for the control system with its

fast thermal response.

• Shorten the control cycle.

The overlap band in the heating and cooling control is set to

a dead band by mistake.

• Set to an overlap band.

Possible cause Countermeasure

Procedure The heater's heating capacity is too large for the heating

capacity of the control target.

• Use a heater with a heating capacity suitable for the control

target.

There is periodic disturbance, which changes the heating

capacity of the control target.

• Change to an environment with as little periodic distur-

bance.

Executing autotuning (AT). • Hunting will not occur once autotuning has been completed.

Loading...

Loading...