184

Determining the Error from the Current Situation for Output Errors

Section 7-7

7-7 Determining the Error from the Current Situation for

Output Errors

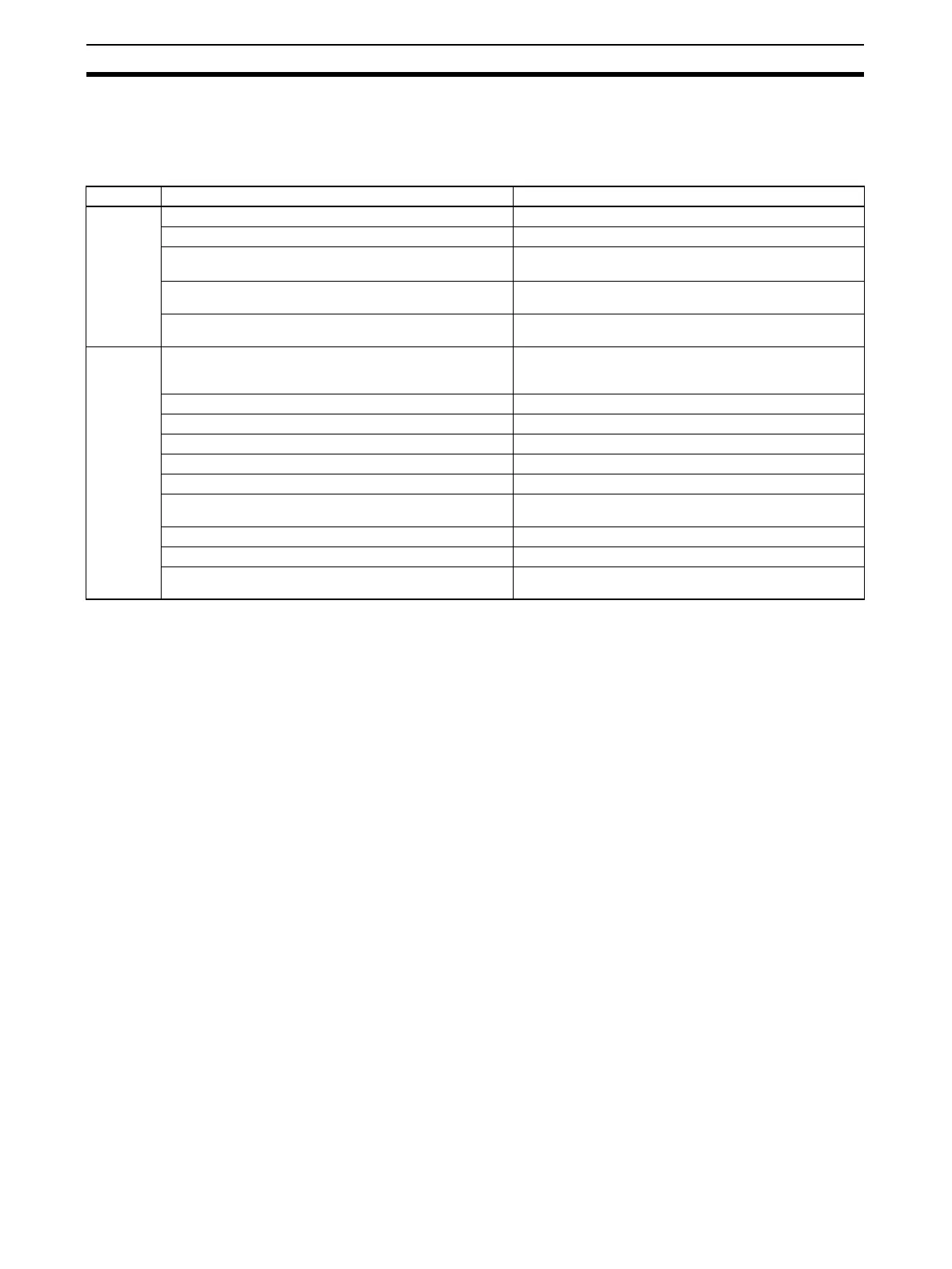

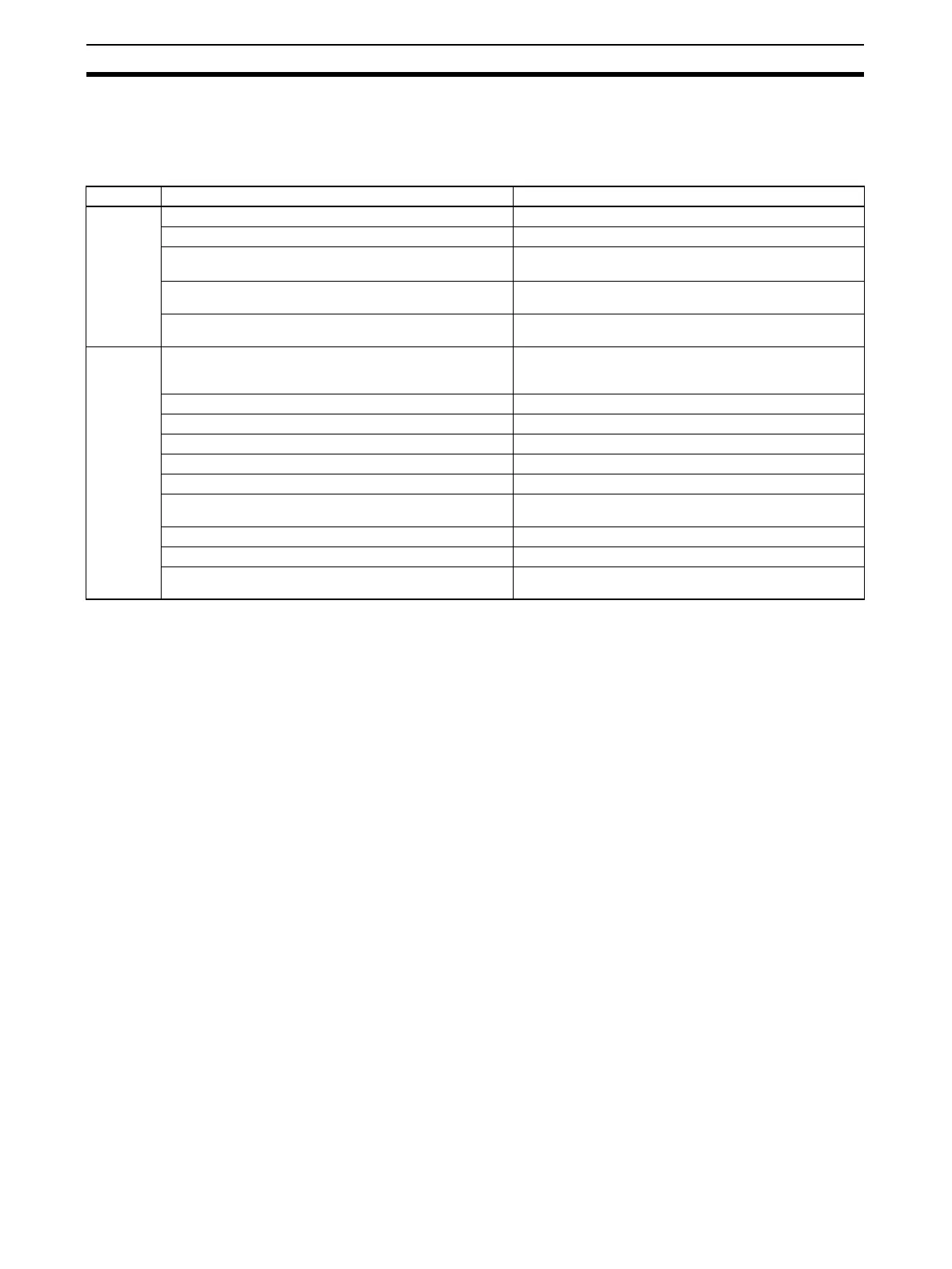

No Control Outputs. No Alarm Outputs.

Possible cause Countermeasure

Connection Measured temperature is wrong. • Perform the action outlined in 7.5.

The load polarity or connected terminals are wrong. • Rewire correctly.

A load exceeding the output rating is connected. • Reduce the load to within the rating.

• Get the Unit repaired if it is malfunctioning.

No power supply for the load is connected to the transistor

outputs.

• Use a power supply suitable for the output rating and load.

The polarity of the load power supply for transistor outputs is

incorrect.

• Rewire correctly.

Setting Set the Operation After Power ON parameter to Stop. • Execute a RUN (start operation) operation command after

the power is turned ON.

• Set the Operation After Power ON parameter to Continue.

Control does not start. • Execute a RUN (start operation) operation command.

The specified channel is incorrect. • Set the correct channel number.

The control output assignments are incorrect. • Set the correct control output assignments.

The set point is incorrect. • Set the correct set point.

The specified bank is incorrect. • Set the correct bank.

A bank specification for all channels has been assigned to

an event input, and an unintended bank has been selected.

• Assign the bank of the channel for which the bank is to be

changed to an event input.

Alarm mode is set to 0 (no alarm). • Set the correct alarm mode.

Alarm mode is set to an alarm with a standby sequence. • Set to an alarm without a standby sequence.

The deviation alarm and absolute-value alarm settings for

alarm mode are incorrect.

• Set the correct alarm mode.

Loading...

Loading...