Description of I/O extension modules

3827_en_B PHOENIX CONTACT 23/138

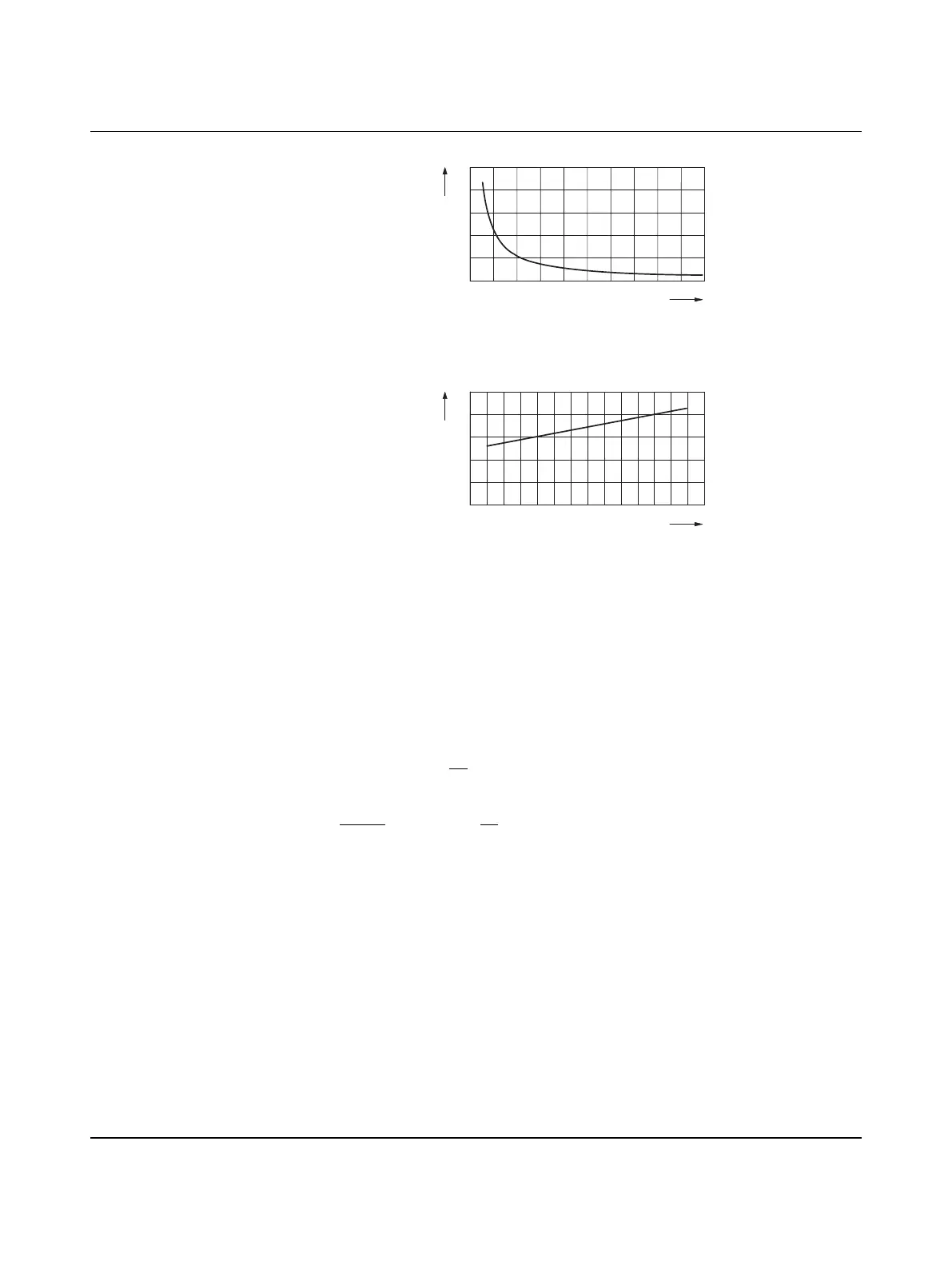

Figure 3-9 Systematic temperature measuring error ΔT depending on the cable cross

section A

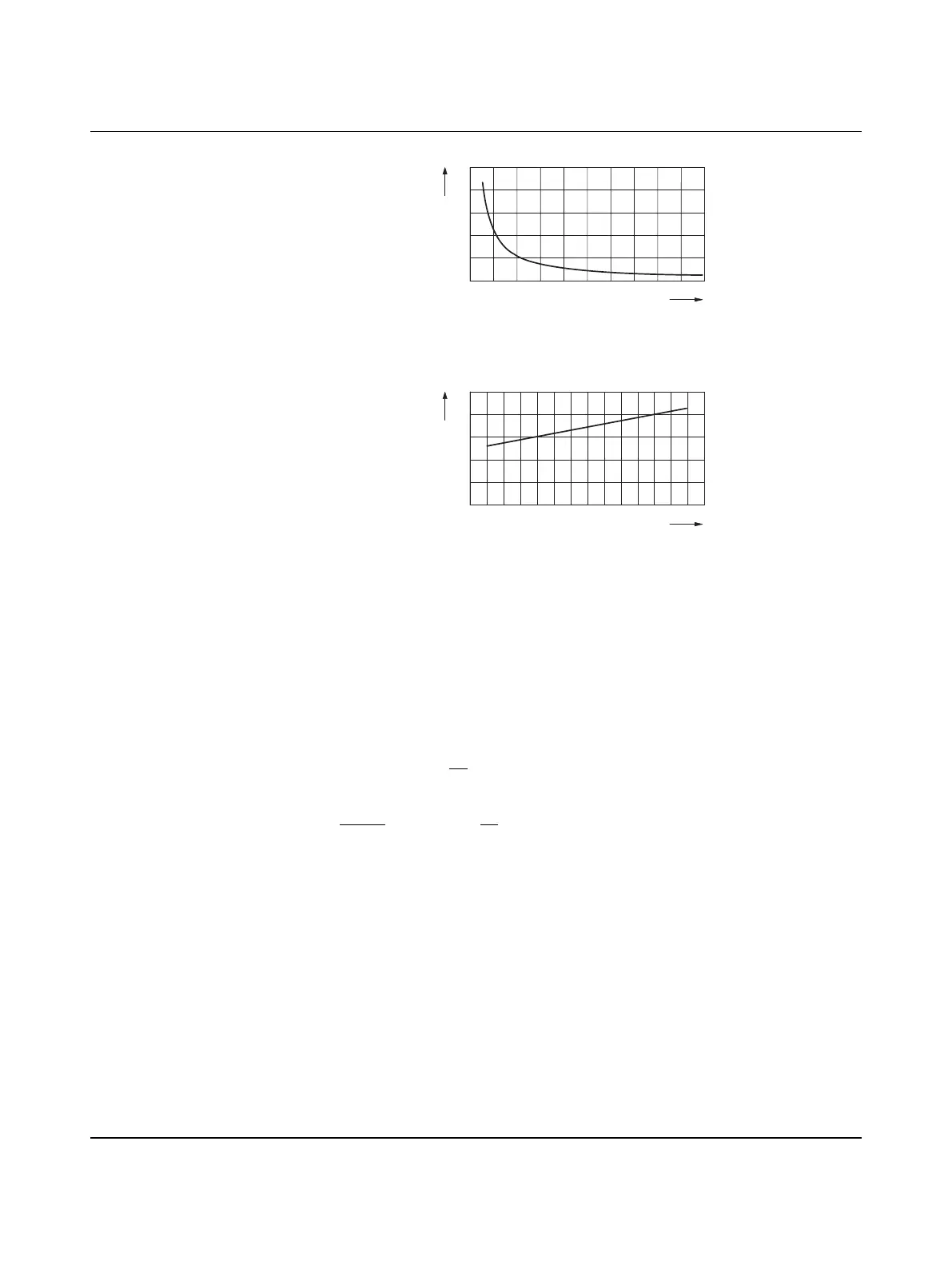

Figure 3-10 Systematic temperature measuring error ΔT depending on the cable

temperature T

A

(Measuring error valid for: copper cable χ = 57 m/Ωmm

2

, T

A

= 25°C and Pt 100 sensor)

Make sure that the cable resistance and therefore the measuring error is as low as possible.

• Use sensor cables that are as short as possible.

• Avoid conductor cross sections smaller than 0.5 mm

2

.

The temperature has only a small influence on the cable resistance.

You can calculate the cable resistance as follows:

Due to there being two cable resistances in the measuring system, the value must be

doubled. Using the average temperature coefficient α = 0.385 Ω/K for Pt 100, the absolute

measuring error in Kelvin can be determined for platinum sensors according to DIN

standards.

R

L

= R

L20

x [1 + 0.0039

1

x (T

A

- 20°C)]

K

R

L

=

l

x [1 + 0.0039

1

x (T

A

- 20°C)]

χ x A K

R

L

Cable resistance in Ω

R

L20

Cable resistance at 20°C in Ω

l Line length in m

χ Specific resistance of copper in m/

Ωmm

2

A Cable cross section in mm

2

0.0039 1/K Temperature coefficient for copper (degree of purity of 99.99%)

T

A

Ambient temperature (cable temperature) in °C

0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0

0

2

4

6

8

10

T [K]

A [mm ]

2

-50 -30 -10 10 30 50 70 90

0

0,5

1

1,5

2

2,5

T [K]

T [°C]

Loading...

Loading...