MAX™ Operator Manual

©

Original Printed In English

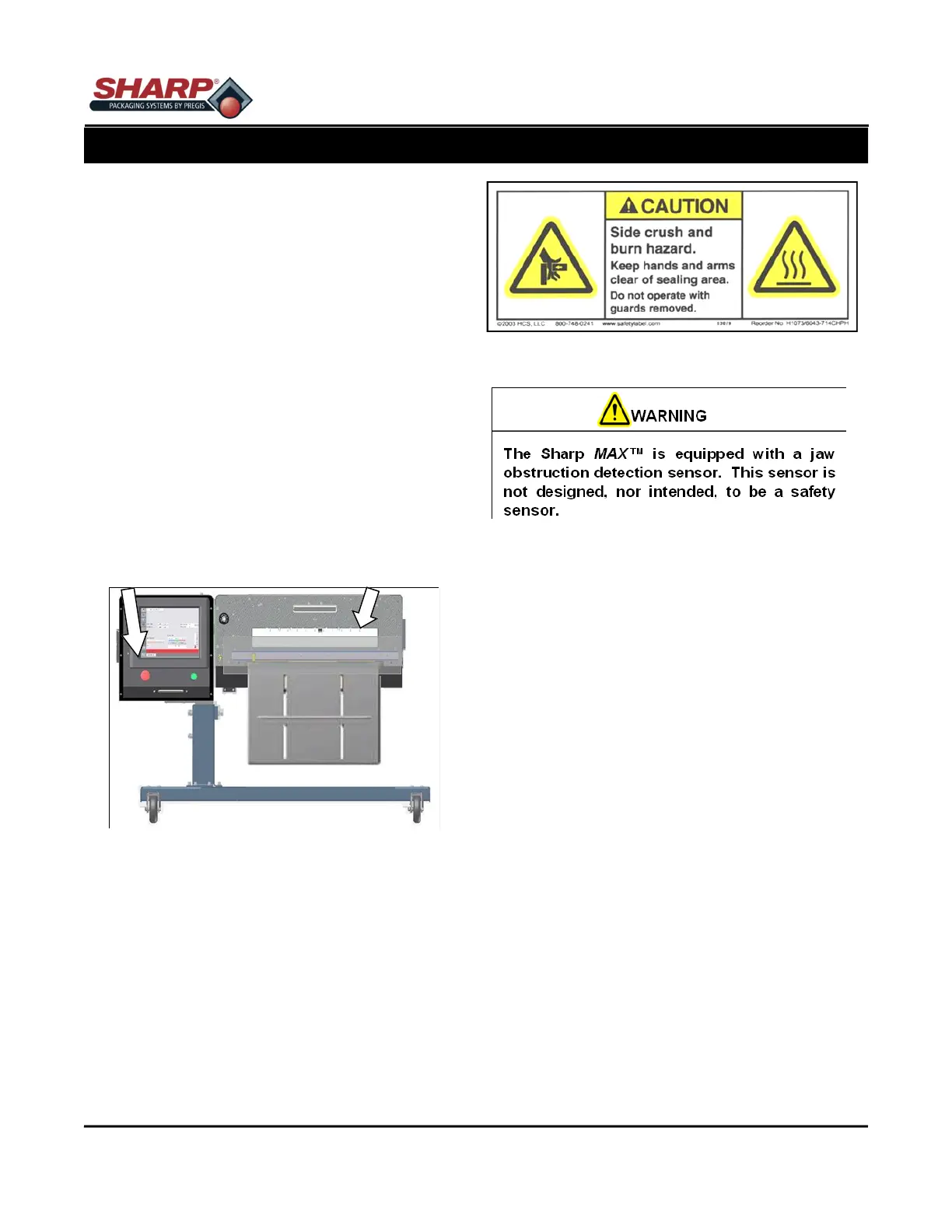

EQUIPMENT SAFETY FEATURES

The Sharp MAX™ is equipped with guards covering

the heated sealing area and the underside of the

Head Assembly. DO NOT operate the MAX™ with

these or any other guards removed.

The Top Lexan® Guard sits on top of the Jaw Guard.

The shape allows for loading of product into the bags.

Sharp Packaging recommends the MAX™ be

equipped with the optional Dual Palm Buttons to start

the cycle to ensure the operator’s hands are clear of

the sealing and pressure bars when the machine is

cycled.

An Emergency-Stop Button is located on the Control

Panel, which immediately stops the machine when

pressed by de-energizing power to the Master Control

Relay, PLC outputs, motor, motor drive and air valves.

Figure 1-3A.

SAFETY LABELS

Figure 1-3B shows a label that is placed on the Sharp

MAX™ wherever a removable guard or panel is at-

tached. Always disconnect electrical power from the

machine prior to removing any guards and/or panels.

OBSTRUCTION SENSING JAW

The Sealing Assembly is equipped with an Obstruc-

tion Sensing Jaw, which can detect an obstruction in

the sealing area. If the jaw sensors detect an object

preventing the jaw from closing, the jaw solenoid will

de-energize and place the machine into a fault condi-

tion.

A message appears in the display window informing

the operator of the jaw fault, allowing the operator to

clear the seal area and reset the bagging cycle.

SECTION 1 - INTRODUCTION

IMPORTANT SAFETY INFORMATION

1-3

Emergency Stop Pushbutton Jaw Guard

Figure 1-3A. Safety Features

Loading...

Loading...