MAX™ Operator Manual

©

Original Printed In English

SECTION 5 - MACHINE OPERA-

OPERATION

Before attempting to operate the machine, read all

information under Important Safety Information, page

1-2 and Controls, page 3-1.

1. Make sure machine is plugged into the properly

grounded outlet and connected to clean dry air

regulated to 80 psi. See Air Pressure Regulator

Adjustment, page 2-1.

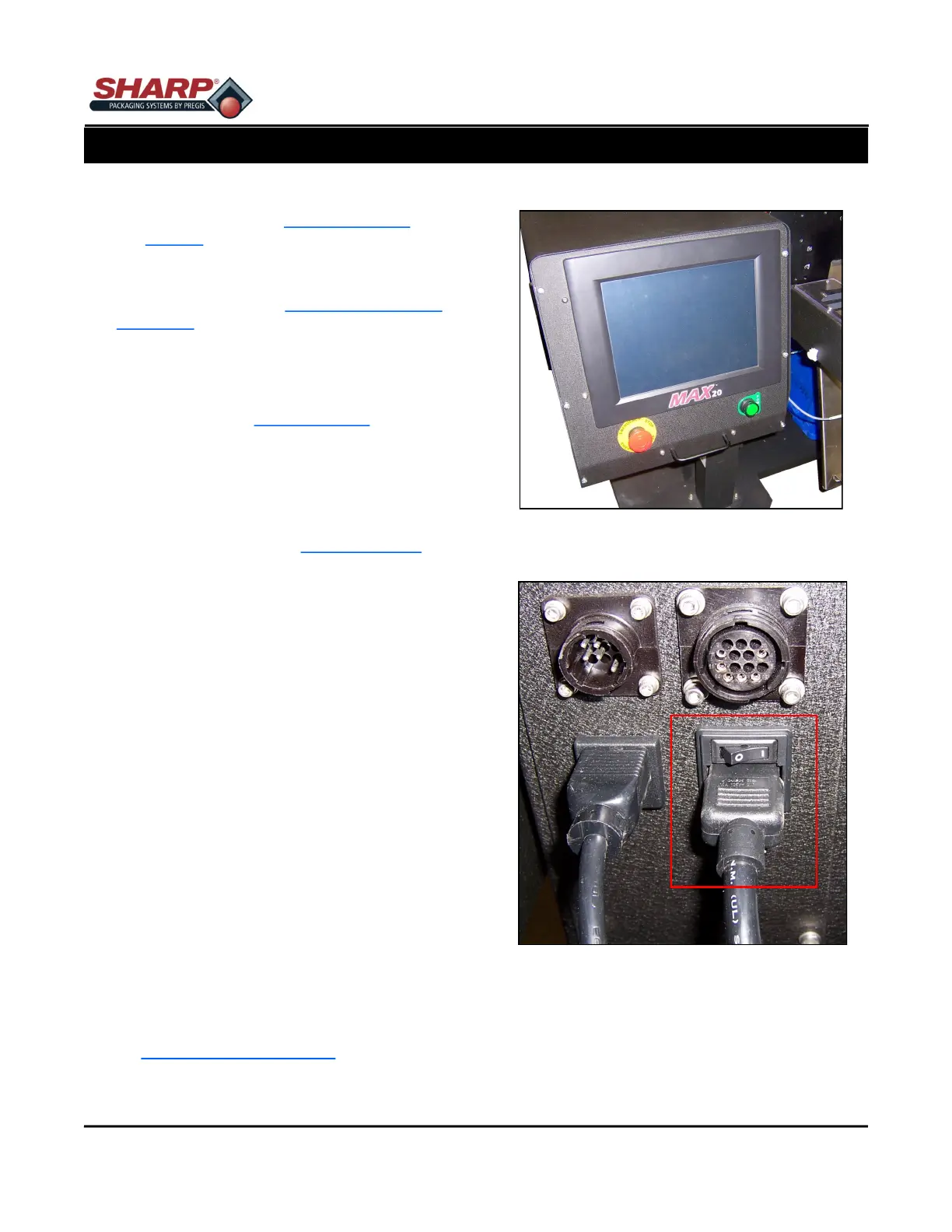

2. Release the E-Stop Button. Figure 5-1A.

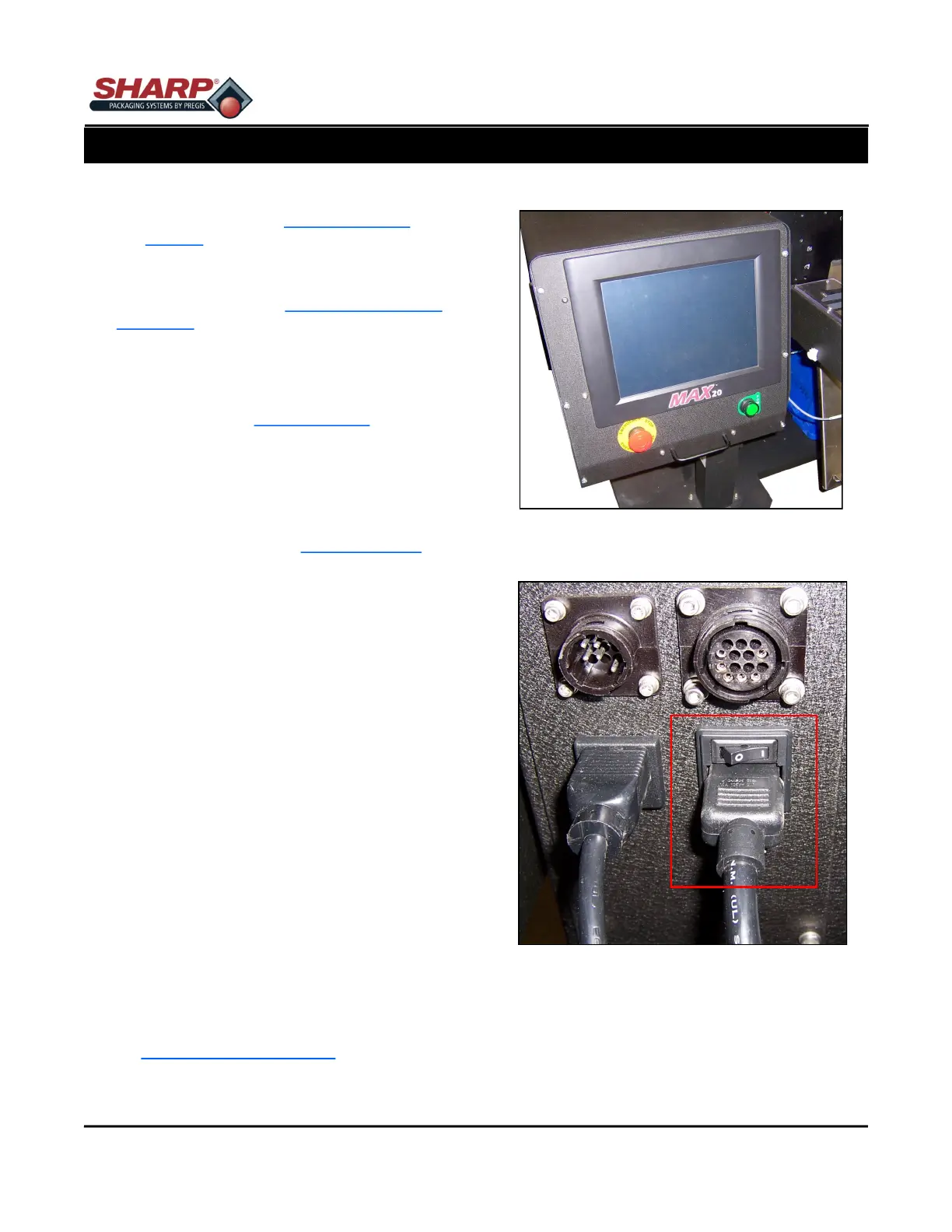

3. Turn on power switch at Power Entry Module. Fig-

ure 5-1B. On CE Models, the PEM is on the Step-

Down Transformer, See Appendix B.

4. Push the green Power Pushbutton. Figure 5-1A.

NOTE: The machine will be in fault status until set

temperature is achieved.

1. Load film material as illustrated in Web Threading

Diagram on machine. See Loading Bag Film,

page 2-2.

NOTE: If an optional Box Power Unwind or Roll

Power Unwind is installed, the Web Threading Dia-

gram will be on the side of power unwind.

2. Load product into bag.

3. Press Foot Control or optional Dual Palm Buttons

to initiate sealing cycle.

NOTE: To stop the machine for any reason, press

the Emergency Stop Button. To completely re-

move all power from the machine turn off the Pow-

er Switch at Power Entry Module or remove Power

Cord.

TECHNICAL ASSISTANCE

Assistance with your Sharp MAX™ can be obtained

by contacting Sharp Packaging Systems Technical

Service Hotline by phone or e-mail. To help serve you

better, Sharp Packaging requests that you provide the

serial number of bagger and a brief description of the

problem.

Phone: +1 (262) 246-8815 (ext. 1572)

E-mail: sharpservice@pregis.com

5-1

Figure 5-1B. Power Entry Module Switch.

Figure 5-1A. E-Stop & Power Pushbutton.

Loading...

Loading...