MAX™ Operator Manual

©

Original Printed In English

1-12

SECTION 1 - INTRODUCTION

THEORY OF OPERATION

output is On. Output 0:3/00 remains on until the terminal count is reached. The parts counting must hand-

shake in accordance with “Sharp Packaging Filler Handshaking Specification”

2. Safety Light Curtain – Hand Load

• When using the Light Curtain in a hand loading operation, the operator places the product into the open

bag. When the operator removes their hand from the safety light curtain, the Parts Counter will increment

by one count. The PLC logic is properly de-bounced to ensure that each entry and exit of the light curtain

produces exactly one count for the parts counter. When the operator has hand loaded the required number

of parts (1-999) the filler Cycle will be initiated and the drop timer will start.

Note: The Safety Light Curtain function is 100% effective in this mode. The Light Curtain will always stop the

machine cycle if it is violated at any time during the bagger cycle

3. Funnel Mounted High Density Light Curtain

• Parts counting can also be accomplished with a High Density light curtain mounted above the funnel open-

ing and wired into the Filler Trigger Input I:2/0. This would not be a safety light curtain. The parts count will

increment by one each time a part drops through the light curtain. An indexing in-feed conveyor could be

used to deliver parts to the funnel. The light curtain must have a resolution that is finer than the smallest

part to ensure that each part breaks the light curtain.

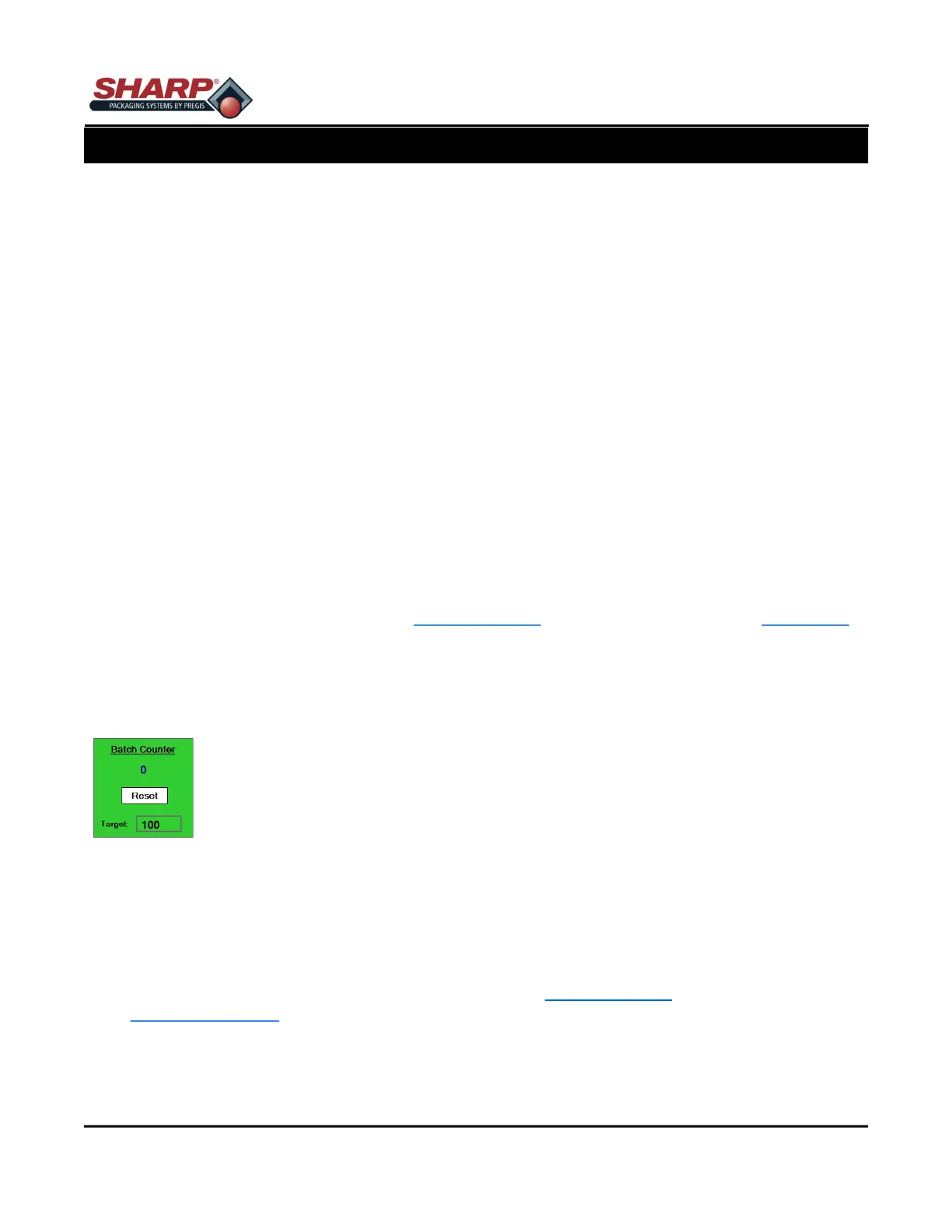

BATCH COUNTER

The Batch Counter is turned on from the Bagger Settings Screen and is viewed from Dashboard

Screen.

The bagger has a setting for Batch Counting. Batch Counting allows a customer to make a run of

products to a particular quantity and then stop the machine. To use this feature, the operator

should cycle the first bag out into the loading position and then reset the counter to 0.

Parts Counter = ON

Target Count - This is the Target Count and can be adjusted by the machine oper-

ator in a range of 1-32767. When the actual count equals this value, the bagger will

stop and cannot be cycled again until this counter is Rest.

Actual Count - The number below “Batch Counter” displays how many bags have

been filled and sealed. The count will be incremented each time the Seal Bar has

retracted.

This counter works in all modes and is not tied to the Parts Counter function.

CONSECUTIVE SEAL BAGS

The Consecutive Seal Bags feature is turned on from the Bagger Settings Screen and is viewed

from Dashboard Screen.

This is a special operating mode that allows multiple filled and sealed bags to be connected to-

gether in a continuous strip. There are restrictions and limitations to this feature. This mode re-

quires that the Operator pay particular attention to keeping the Drive Rollers cleaned and in good

Loading...

Loading...