5-12

VIBXPERT II 05.2012

Shaft centerline plot

A shaft centerline plot records the movement of the shaft axis* in a

journal bearing while the machine is running up or coasting down

(e.g. turbine). Conclusions can be drawn from the shaft centerline

plot on the fault conditions - such as oil whirl or oil whip in journal

bearings.

A description of the measurement procedure with VIBXPERT can

befoundintheTechnicalInformationCM#18'Analysisofradial

shaft movement in journal bearings’ - available free on our website.

A shaft centerline plot can be set up via the following task:

2-channel coastdown - phase, meas. quantity: displacement

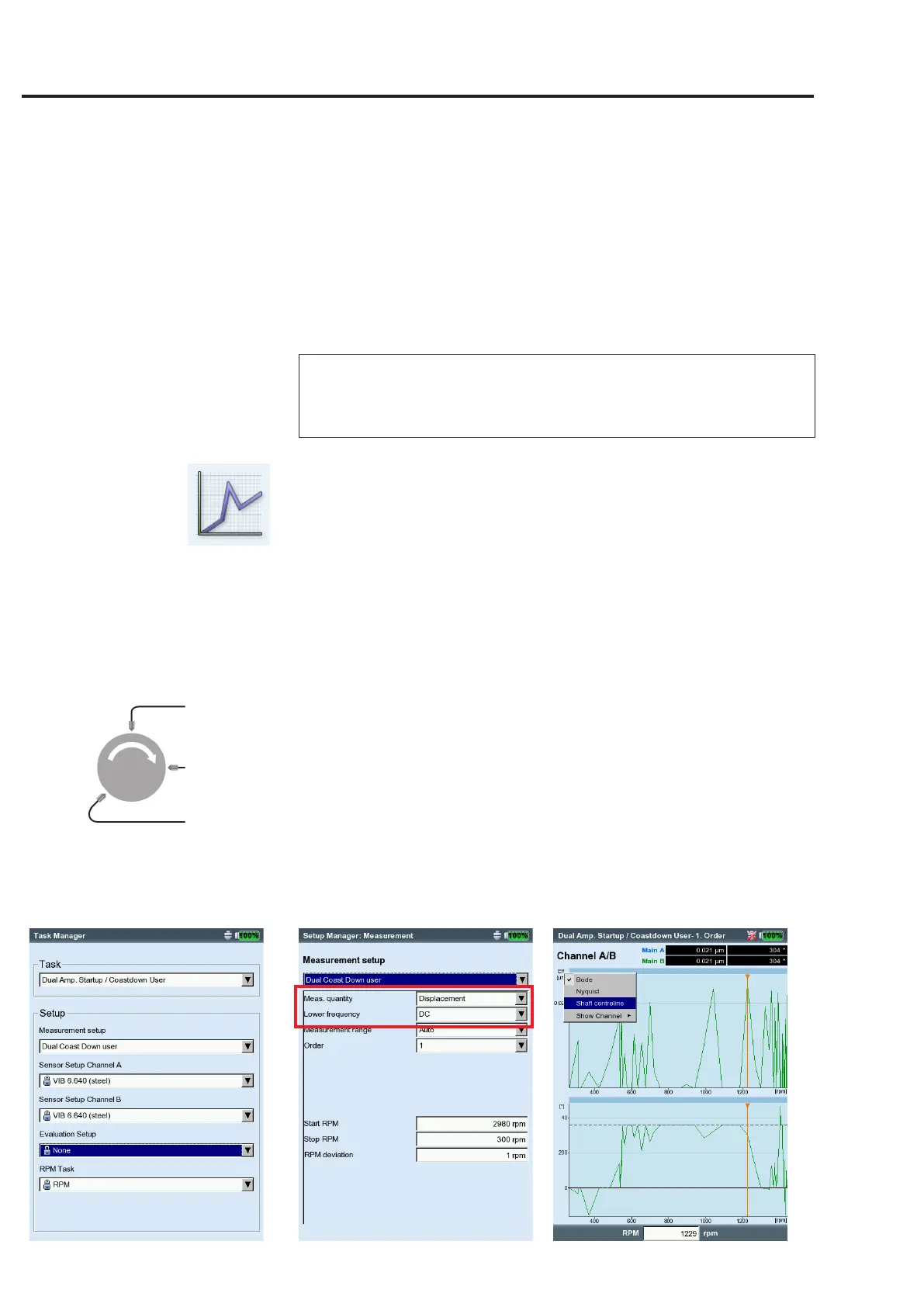

Parameters set up in the measurement task manager (see below)

• As the measurement task, select 'Dual Amp. Startup/Coastdown

User'(seep.5-7).

• Asthemeasurementsetup,select'DualCoastDownUser'.

• Setthefollowingparametersinthemeasurementsetup:

-

measurement quantity = Vibration displacement

-

lower frequency = DC

• In the sensor setup, select the displacement sensors (e.g. VIB

6.640).

Requirements for correctly interpreting the results

- Thesensorsareinstalledatanangleof90°toeachother.

- The shaft always turns from sensor A to sensor B. The position of

the sensor relative to the direction of rotation can be adjusted after

measurement.

- The static shaft position can be displayed as an offset in the shaft

centerline plot.

* The movement of the shaft axis at a

constant rpm is recorded with an orbit

plot (p. 5-16).

Channel A

Channel B

RPM

Shaft centerline plot

Setups in the task manager Parameters in the meas. setup

Results display

Measurement tasks

Note

Loading...

Loading...