5-25

VIBXPERT II 05.2012

Measurement tasks

Impact test - 1 channel

The Impact test is used to determine the resonance frequency of a

structure. In the case of a rotating machine, it is possible to determine

the RPM ranges in which vibrations are disproportionately amplified

by resonance* and could damage the machine. These ranges must

then be avoided during operation and should be passed through as

quickly as possible during runup and coastdown of the machine.

The one-channel impact test only records the system response. The

two-channel impact test also records the excitation.

Almost any source of vibration that contains as many frequencies as

possible is suitable for exciting a structure - such as a pulse-blow with

a rubber hammer.

• Checkandchangethemeasurementparameters,ifnecessary.

The measurement can take place with the machine running or at a

standstill. The signals from a running machine can be filtered out

using the so-called 'negative averaging method'.

• Attachthe transducertothemachine- eitherwithamagnetor,

even better, with a screw fitting.

• Setthenumberofindividualmeasurementsinthemeasurement

setup (e.g. 2 measurements, see below).

• Startthemeasurementbyclickingonthetaskicon(seeabove).

• Whenthemessage'Waitfortrigger'appears,excitethemachine

withasuitablerubberhammer:Strikeneartoandinthedirection

of the transducer once per measurement.

• Foreachsinglemeasurement,strikeexactlythesamelocationonce

with the hammer.

After each single measurement, the result can be accepted or dis-

carded (see below). After all measurements have been completed, the

averaged final result appears together with the 10 highest amplitudes

in the spectrum.

* e.g. excited by an imbalance or mis-

alignment

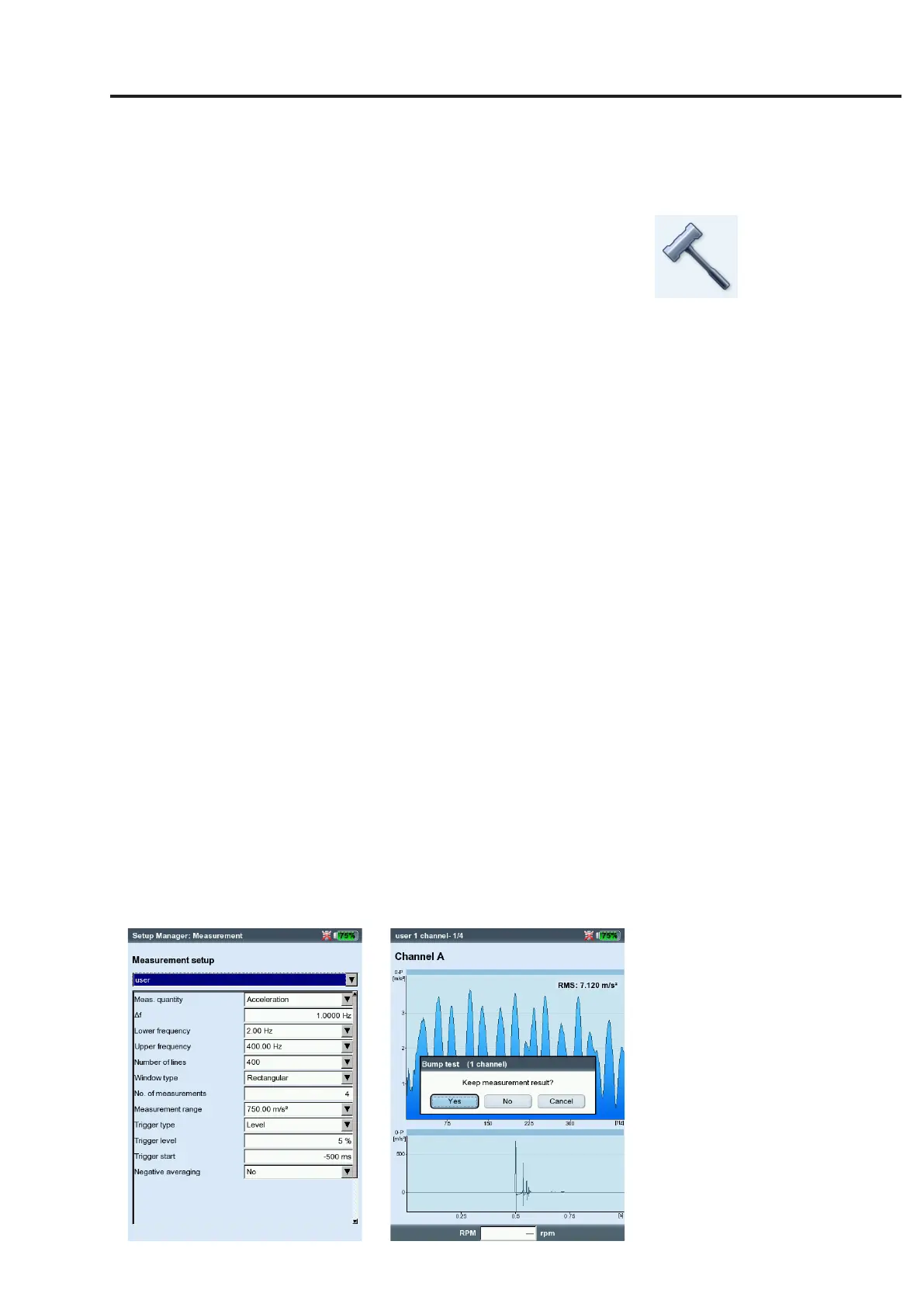

Left:

Setup parameters for impact test

Trigger Start < 0 : Signal is also recorded

before the excitation

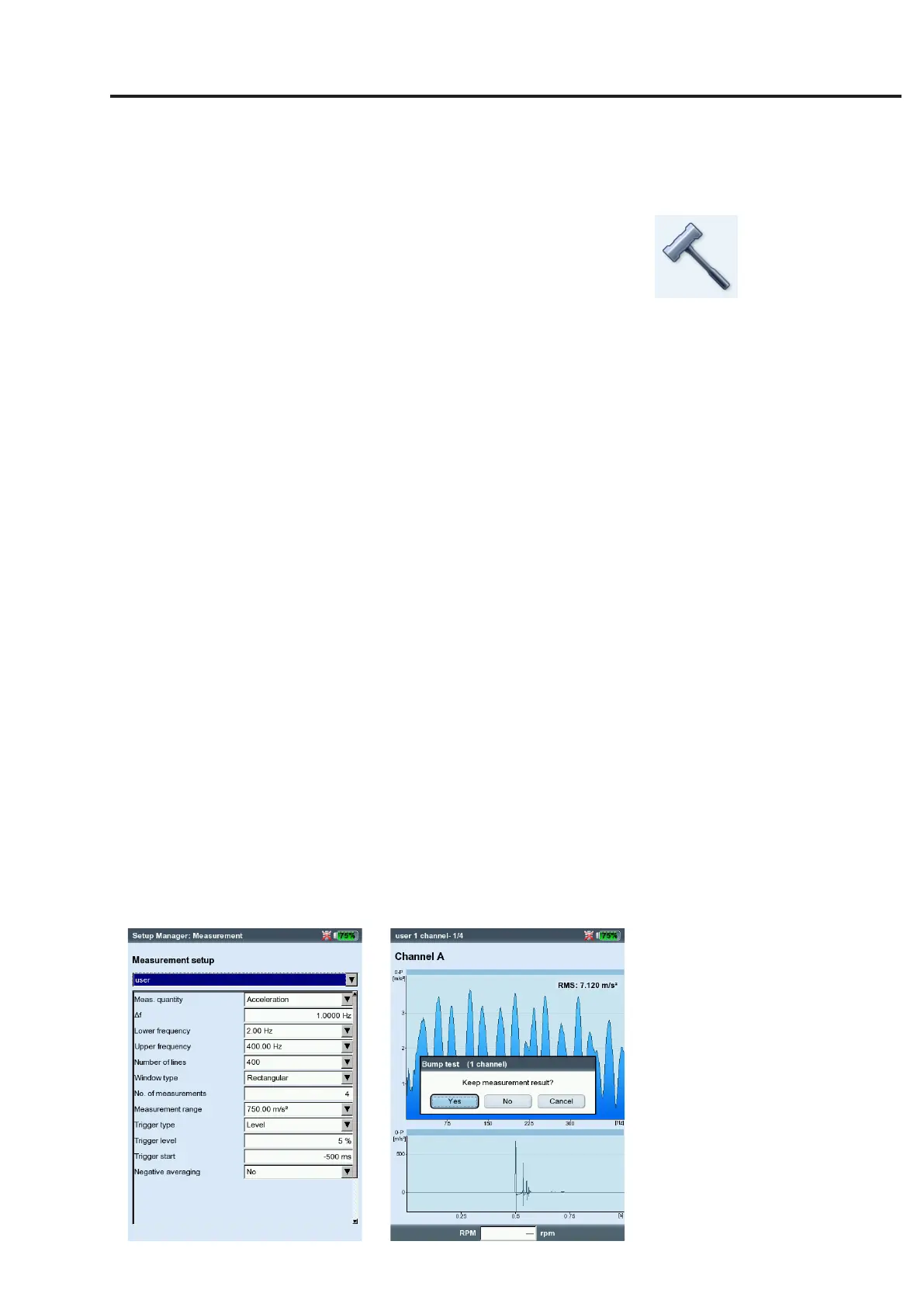

Right:

Measurement after hammer strike

Spectrum with resonant frequencies and

measured time signal

Impact test

Loading...

Loading...