MX-3114N SIMULATION 6 – 17

9

9-2

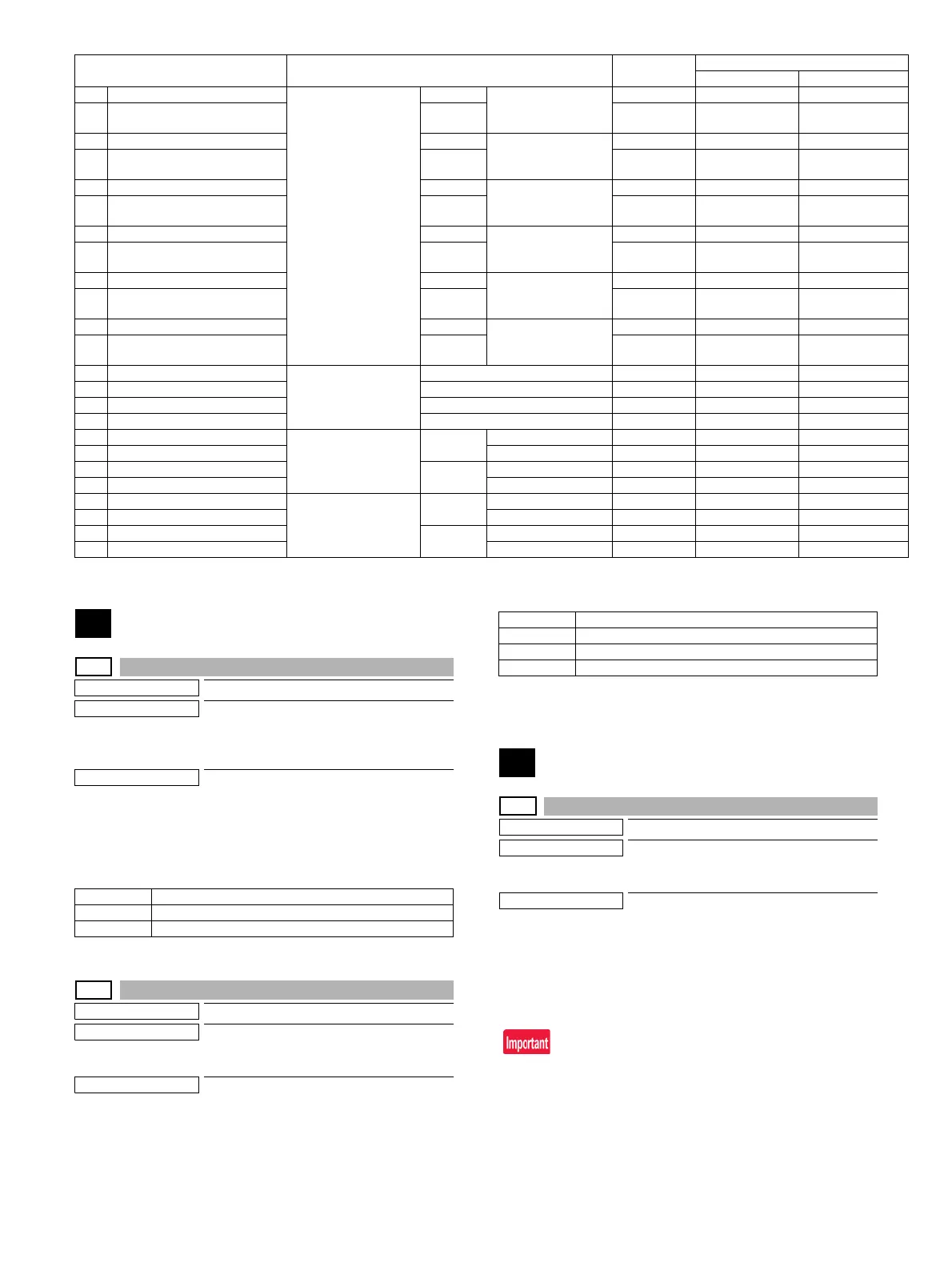

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the sen-

sors and detectors in the paper reverse

section (duplex section) and its control cir-

cuit.

Section

Duplex

Operation/Procedure

The operating conditions of the sensors and detectors are dis-

played.

The code names of the sensors and the detectors which are active

are highlighted.

9-3

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the load in

the paper reverse section (duplex section)

and its control circuit.

Section

Duplex

Operation/Procedure

1) Select the item to be operation checked with the touch panel

key.

2) Press [EXECUTE] key.

The selected load performs the operation.

When [EXECUTE] key is pressed, the operation is terminated.

*: Not used, but the button is displayed.

10

10-1

Purpose

Operation test/check

Function (Purpose)

Used to check the operations of the toner

supply mechanism (toner motor) and the

related circuit.

Section

Process (Developing)

Operation/Procedure

1) Select a target of the operation check with the touch panel key.

When [ALL] key is pressed, all the items are selected.

2) Press [EXECUTE] key.

The selected load operation is performed for 10 sec.

When [EXECUTE] key is pressed, the operation is terminated.

This simulation must be executed without installing the toner car-

tridges.

If this simulation is executed with the toner cartridges installed,

toner will be forcibly supplied to the developing unit, resulting in

overtoner.

If this simulation is erroneously executed with the toner cartridges

installed, overtoner state may be deleted by making a few black

background copy in the single color copy mode of the target color.

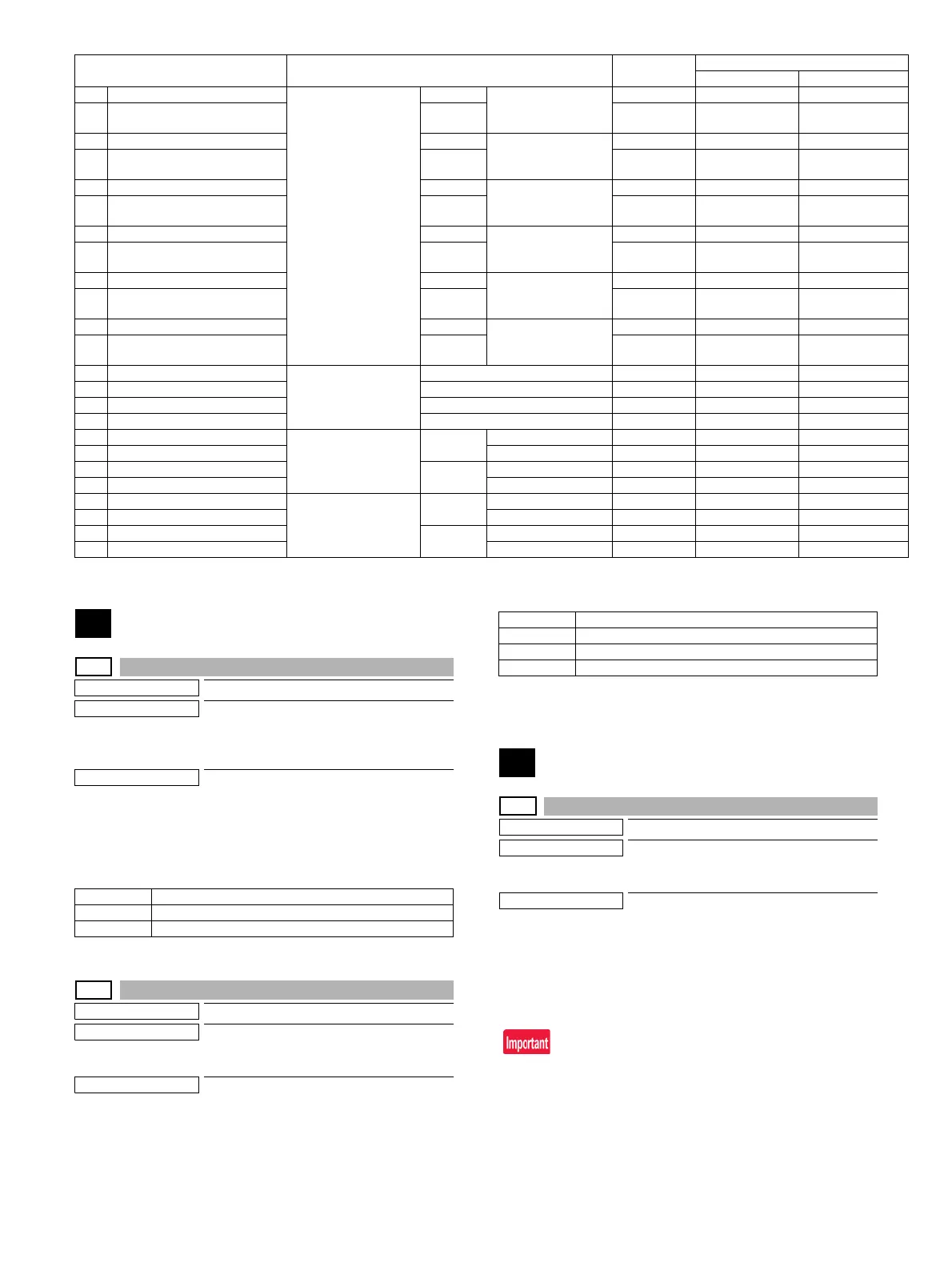

S TC2 HEAVY2 CL Secondary transfer bias

adjustment value

Color

Heavy paper 2

51 - 255 83 83

T TC2 HEAVY2 BW

Black/

White

51 - 255 69 69

U TC2 HEAVY3 CL Color

Heavy paper 3

51 - 255 83 83

V TC2 HEAVY3 BW

Black/

White

51 - 255 69 69

W TC2 OHP CL Color

OHP

51 - 255 69 69

X TC2 OHP BW

Black/

White

51 - 255 69 69

Y TC2 ENVELOPE CL Color

Envelope

51 - 255 69 69

Z TC2 ENVELOPE BW

Black/

White

51 - 255 69 69

AA TC2 THIN CL Color

Thin paper

51 - 255 96 103

AB TC2 THIN BW

Black/

White

51 - 255 96 103

AC TC2 GLOSSY CL Color

Gloss paper

51 - 255 83 83

AD TC2 GLOSSY BW

Black/

White

51 - 255 69 69

AE TC2 CLEANING

Secondary transfer

cleaning bias

adjustment value

Cleanig process (negative pole) 51 - 255 59 59

AF TC2 CLEAN LOW SPD Low speed print mode 0 - 255 26 26

AG TC2 CLEAN MIDDLE SPD Middle apeed print mode 0 - 255 26 26

AH TC2 CLEAN CLEANING Cleaning bias (positive pole) 0 - 255 102 102

AI PTC LOW SPEED CL

PTC current adjustment

value

Color

Low speed 51 - 255 73 73

AJ PTC MIDDLE SPEED CL Middle apeed 51 - 255 73 73

AK PTC LOW SPEED BW

Black/

White

Low speed 51 - 255 73 73

AL PTC MIDDLE SPEED BW Middle apeed 51 - 255 73 73

AM CASE VOLT LOW CL

PTC voltage adjustment

value

Color

Low speed 0 - 255 0 0

AN CASE VOLT MID CL Middle apeed 0 - 255 0 0

AO CASE VOLT LOW BW

Black/

White

Low speed 0 - 255 0 0

AP CASE VOLT MID BW Middle apeed 0 - 255 0 0

Item/Display Content Setting

value

Default value

23cpm 26cpm/31cpm

APPD1 ADU paper transport detector 1

APPD2 ADU paper transport detector 2

DSW_ADU ADU paper guide open/close detector

Display Content

ADUC1 ADU transport clutch 1 (*)

ADUM ADU motor

ADUGS ADU gate solenoid (26cpm/31cpm)

Loading...

Loading...