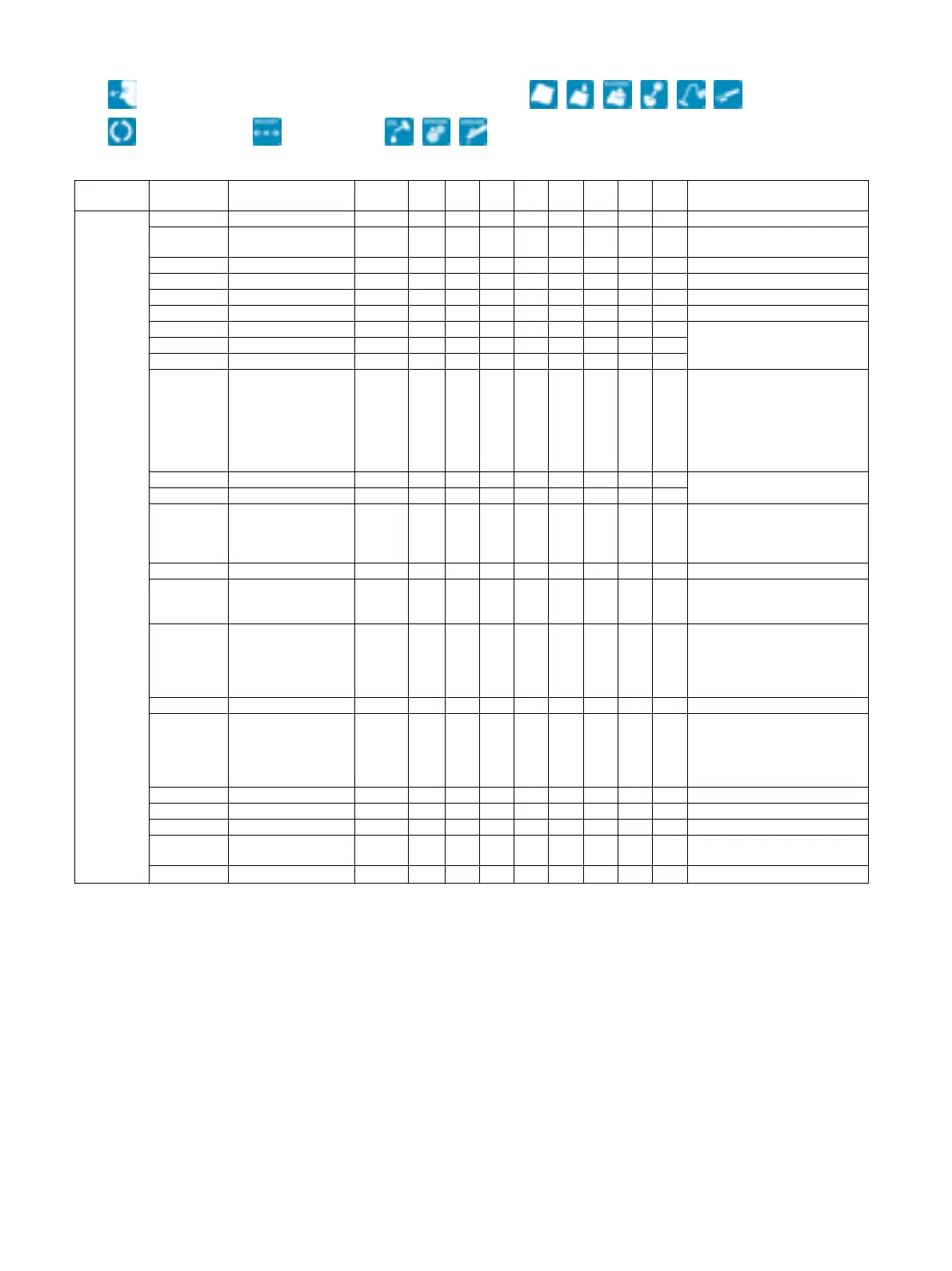

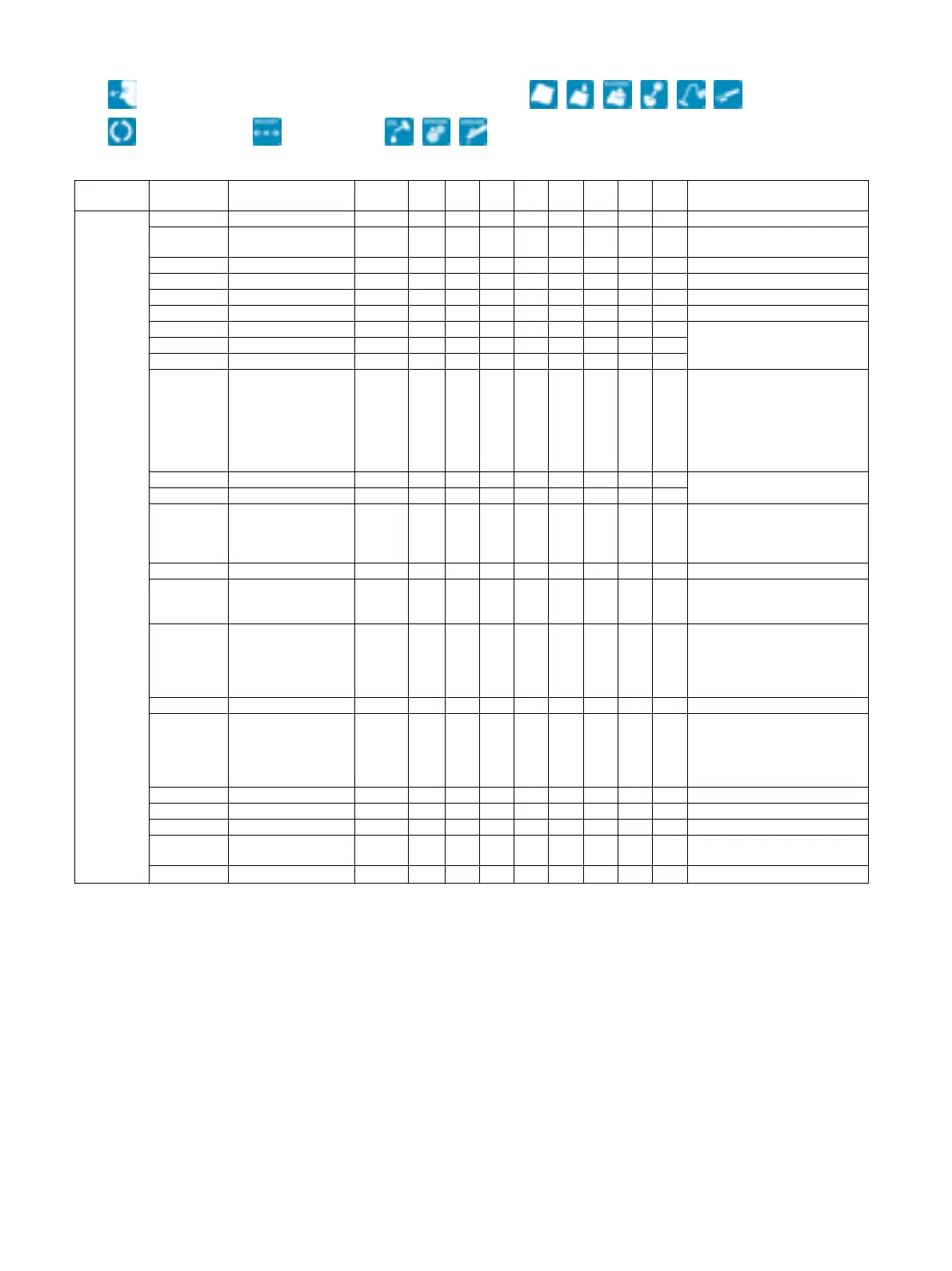

MX-3114N MAINTENANCE 9 – 35

K. Fusing section

23 cpm machine

Unit name

Parts work

sequence

Part name

When

calling

100

K

200

K

300

K

400

K

500

K

600

K

700

K

800

K

Remark

Fusing unit 1 Lower separation pawl ✕ – ✕ – ✕ – ✕ – ✕

2 Lower separationpawl

spring

✕ – ✕ – ✕ – ✕ – ✕

3 Separation plate ✕ – ✕ – ✕ – ✕ – ✕

4 Oil applying roller ✕

5 Backup roller ✕

6 CL roller bearing ✕

7 Lower thermistor ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed.

8 Pressure roller gear ✕ – ✕ – ✕ – ✕ – ✕

9 Pressure roller bearing ✕ – ✕ – ✕ – ✕ – ✕

10 Pressure roller ✕ – – –

– Apply grease to the shaft section

when replacing. (JEF552) / After

completion of replacement, clean

the new pressure roller surface

with alcohol. / Integrated with the

fusing roller as a maintenance kit.

Replace at every 200K.

11 Sub thermistor ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed.

12 Fusing roller bearing ✕ – ✕ – ✕ – ✕ – ✕

13 Heat-insulating bush ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed. / When

replacing, apply grease to the

inner ring section and the outer

ring section. (JEF552)

14 Heating roller bearing ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed.

15 Fuser belt guide collar ✕ Integrated with the fusing belt as

a maintenance kit.

Replace at every 100K.

16 Fusing roller ✕ – – – – Apply grease to the shaft section

when replacing. (JEF552) /

Integrated with the pressure roller

as a maintenance kit.

Replace at every 200K.

17 Heating roller ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed.

18 Fusing belt ✕ Integrated with the fuser belt

guide collar as a maintenance kit.

/ When replacing, clean the fusing

belt surface with alcohol.

Replace at every 100K.

19 Main thermistor ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed.

20 Paper guides – – –

–

21 Gears ✕ – ✕ – ✕ – ✕ – ✕ Replace as needed.

22 Lower scraper

assembly

✕

23 Washer ✕ – ✕ – ✕ – ✕ – ✕

g Check (Clean, replace, or adjust according to necessity.) Ũ : Clean

Ţ : Replace : Lubricateţ : Adjust ŭ

Loading...

Loading...