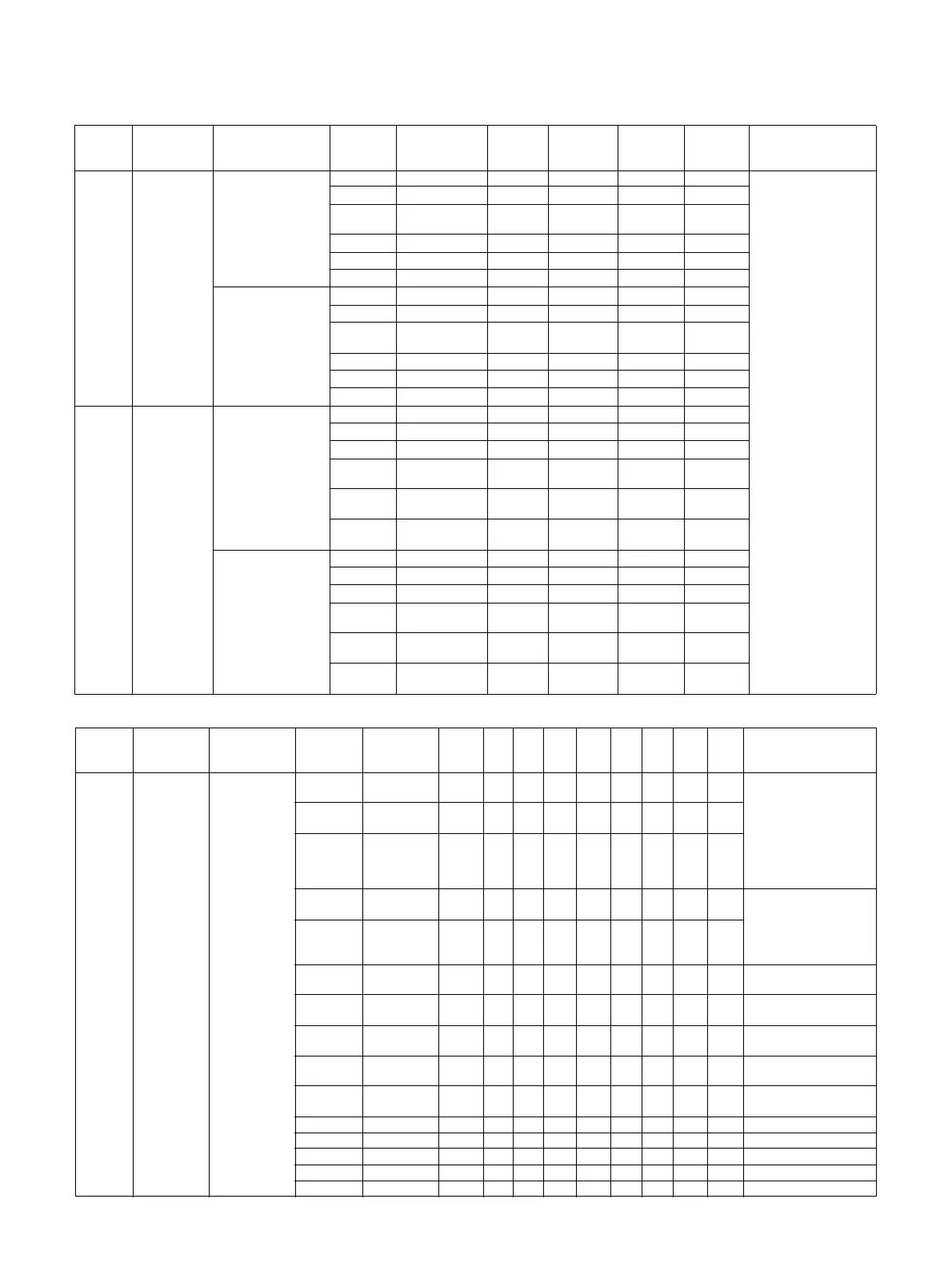

MX-3114N MAINTENANCE 9 – 4

3. Maintenance list

Main unit

✕: Check (Clean, replace, or adjust according to necessity.) : Clean : Replace : Adjust ✩: Lubricate

23 cpm

Section/

Unit work

sequence

Section name Unit name

Parts work

sequence

Part name

When

calling

840 K

rotation

840 K

rotation

840 K

rotation

Remark

1 Developing

section

Developing unit

(monochrome)

1 Developer ✕ 840K rotation or

Maximum printable

number

23cpm:120K(BK)/

100K(CL)

26cpm:140K(BK)/

140K(CL)

31cpm:155K(BK)/

140K(CL).

2DV seal

✕✕ ✕✕

3 DV side seals

F/R

✕✕ ✕✕

4 Toner filter

✕✕ ✕✕

5 Bias pin ✕

✕✕✕

6 Connector

✕✕ ✕✕

Developing unit

(color)

1 Developer

✕

2DV seal

✕✕ ✕✕

3 DV side seals

F/R

✕✕ ✕✕

4 Toner filter

✕✕ ✕✕

5 Bias pin ✕

✕✕✕

6 Connector

✕✕ ✕✕

2 OPC drum

section

OPC drum unit

(monochrome)

1Drum

✕

2MC unit

✕

3 Cleaning blade

✕

4 Toner reception

blade

✕✕ ✕✕

5 Side seals

F/R

✕✕ ✕✕

6 Charger

cleaner

✕

OPC drum unit

(color)

1Drum

✕

2MC unit

✕

3 Cleaning blade

✕

4 Toner reception

blade

✕✕ ✕✕

5 Side seals

F/R

✕✕ ✕✕

6 Charger

cleaner

✕

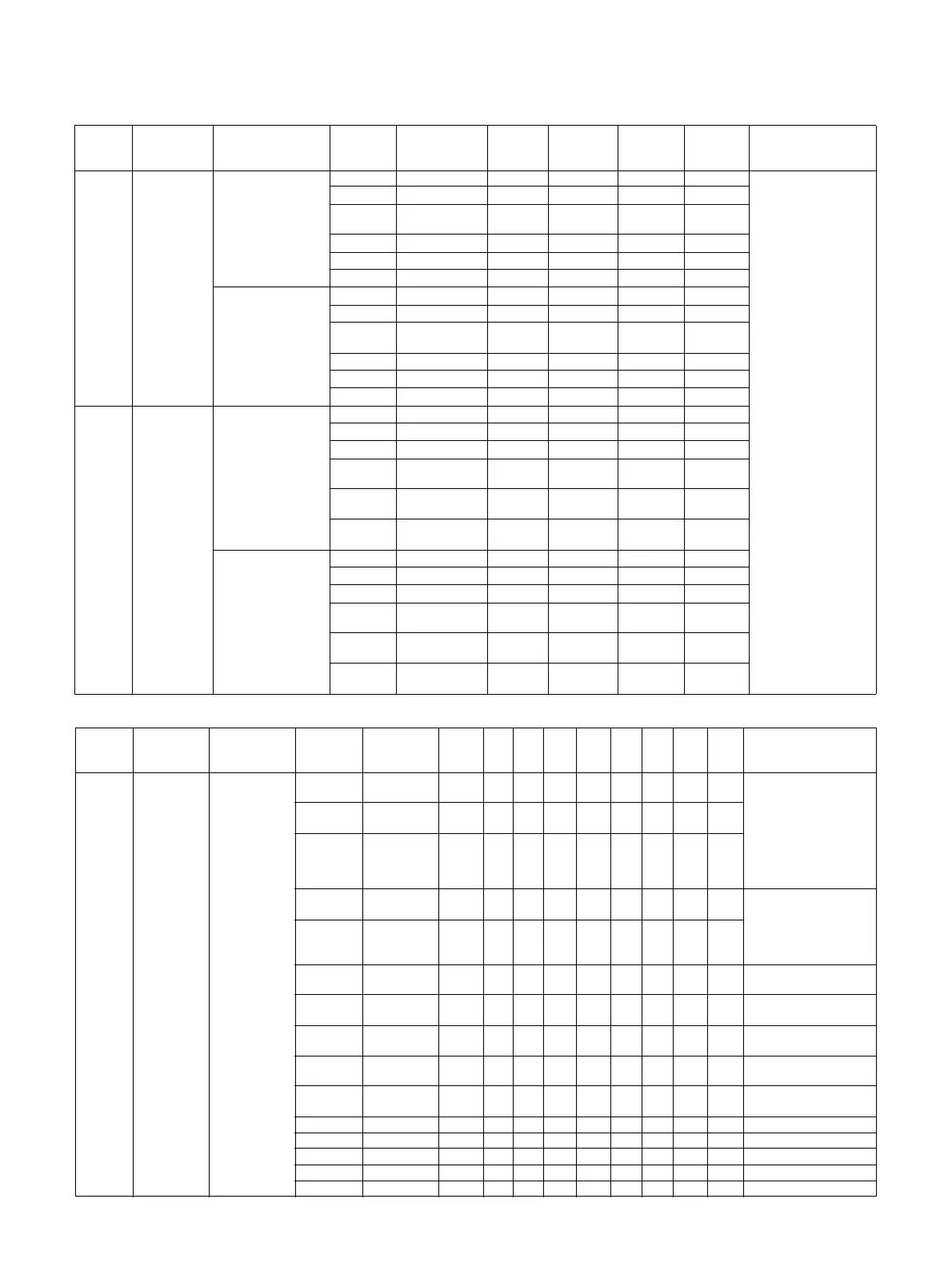

Section/

Unit work

sequence

Section name Unit name

Parts work

sequence

Part name

When

calling

100

K

200

K

300

K

400

K

500

K

600

K

700

K

800

K

Remark

1RSPF

section

RSPF unit 1 Document

pickup roller

Replace at 100K of the

SPF paper feed counter

or 1 year of use.

When replacing the

paper feed roller, apply

grease to the paper feed

shaft.

GP-501MR

2 Paper feed

roller

3 Separation

roller

4 Torque

limiter SPF

✕✕✕✕✕✕✕✕✕Replace at 400K of the

SPF paper feed counter

or 2 years of use.

5 Take-up

torque

limiter

✕✕✕✕✕✕✕✕✕

6 Discharge

brush

✕✕✕✕✕✕✕✕✕

7 Registration

roller

8 Transport

roller 2

9 Transport

roller 3

10 Paper exit

roller

11 Sensors ✕✕✕✕✕✕✕✕✕

12 Scan plate

13 Gears ✕✕✕✕✕✕✕✕✕

14 Belts ✕✕✕✕✕✕✕✕✕

15 OC mat

Loading...

Loading...