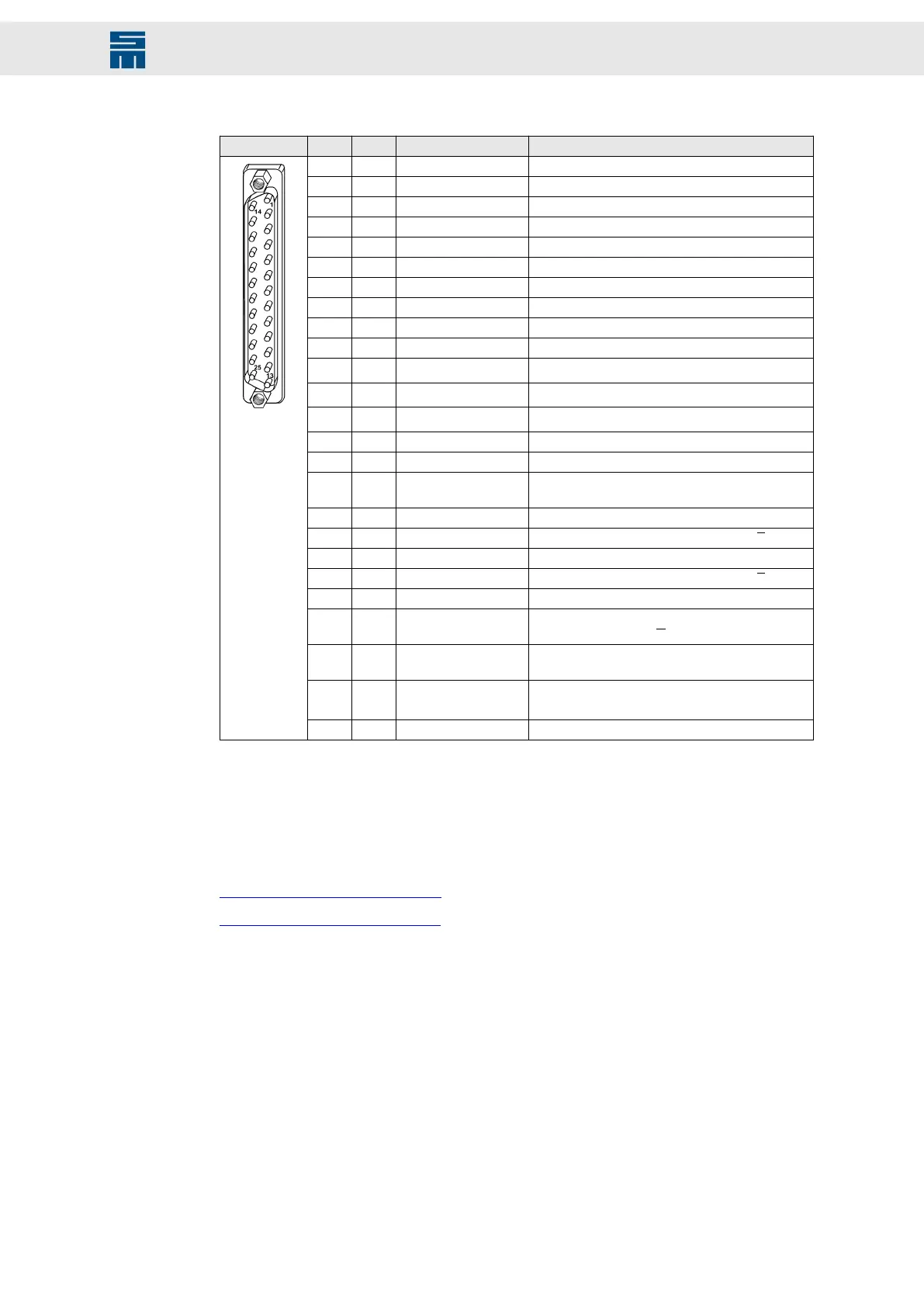

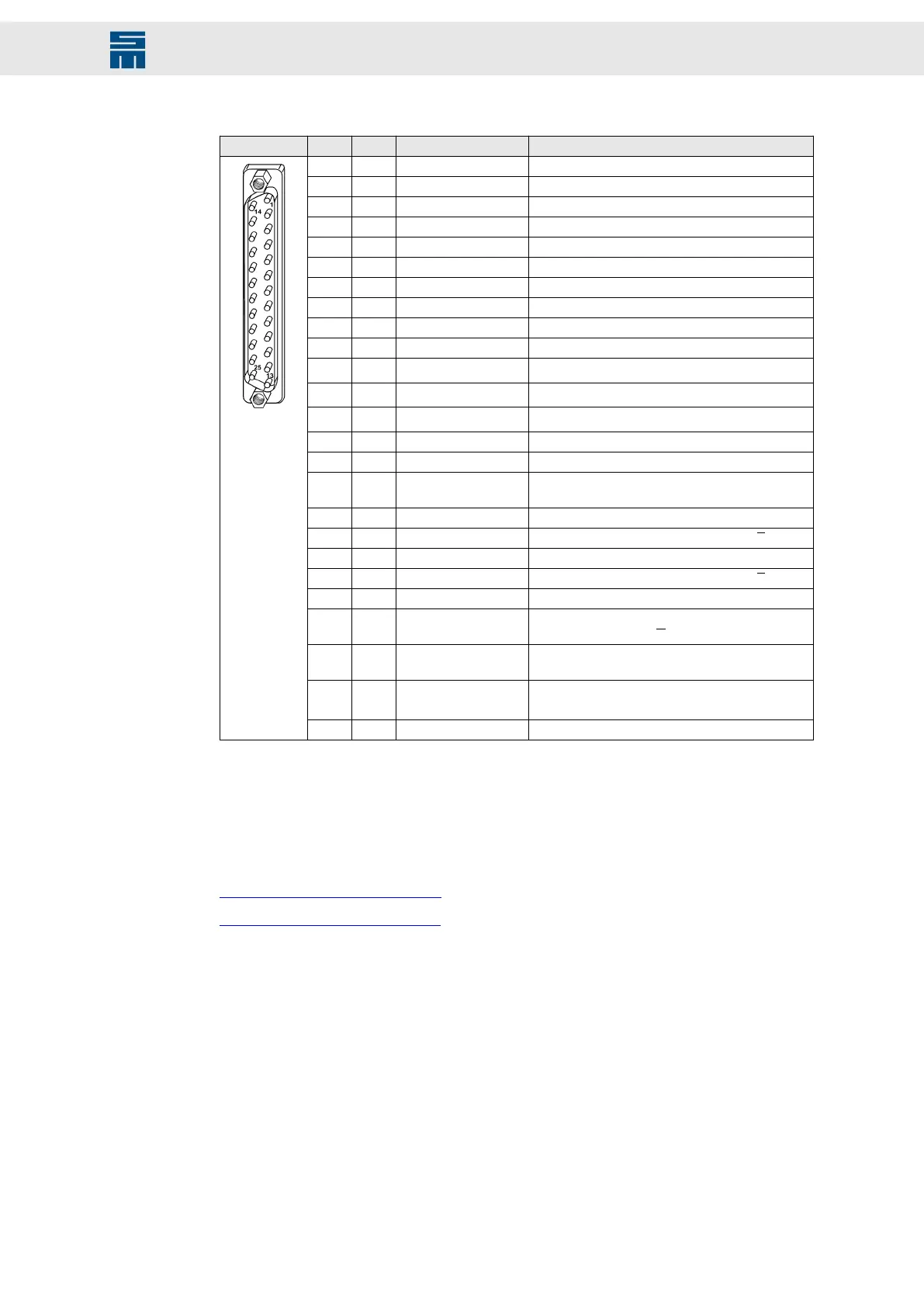

25-pole male submin D connector

X17 Pin I/O Name Meaning

1 I S2 Resolver S2

2 I S1 Resolver S1

3 I R3 Resolver R3

4 I R1 Resolver R1

5 I S4 Resolver S4

6 I S3 Resolver S3

7 I COS- SinCos/linear Hall Cosine-

8 I COS+ SinCos/linear Hall Cosine+

9 I SIN- SinCos/linear Hall Sine-

10 I SIN+ SinCos/linear Hall Sine+

11 I

HALL_C / IN4

(1)

Hall sensor 12 V track C / digital 5 V input 4

12 I

HALL_B / IN3

(1)

Hall sensor 12 V track B / digital 5 V input 3

13 I

HALL_A / IN2

(1)

Hall sensor 12 V track A / digital 5 V input 2

14 I/O GND Ground

15 I/O GND Ground

16 I TEMP Motor temperature (to be connected towards

GND)

17 I FP_IN Field plate sensor

18 I/O UB−/DATA− Encoder B− / Hall sensor 5 V differential B

19 I/O UB+/DATA+ Encoder B+ / Hall sensor 5 V differential B

20 I/O UA−/Clk− Encoder A− / Hall sensor 5 V differential A

21 I/O UA+/Clk+ Encoder A+ / Hall sensor 5 V differential A

22 I UN- Encoder ZP− / SinCos encoder zero pulse / Hall

sensor 5 V differential C

23 I UN+ Encoder ZP+ / SinCos encoder zero pulse + / Hall

sensor 5 V differential C

24 O VCC_FB Measuring system supply 5.3 V / 12 V (max.

4 W)

(2)

25 I ERR / PULSE IN Measuring system error

(1)

You can use the physical inputs HALL A to C also as the configurable, digital 5 V inputs IN2 to IN4.

(2)

Refer to the connection examples for the allowed voltage that is set by the software depending on the

selected measuring system.

Locking bolts flange: max. tightening torque = 0.7 Nm

Related topics

X17 – Motor Feedback, page 68

X16/17 – Digital Inputs, page 67

53Drive System SD2M - Hardware Description 036228xxF

Connector Pin Assignment

Loading...

Loading...