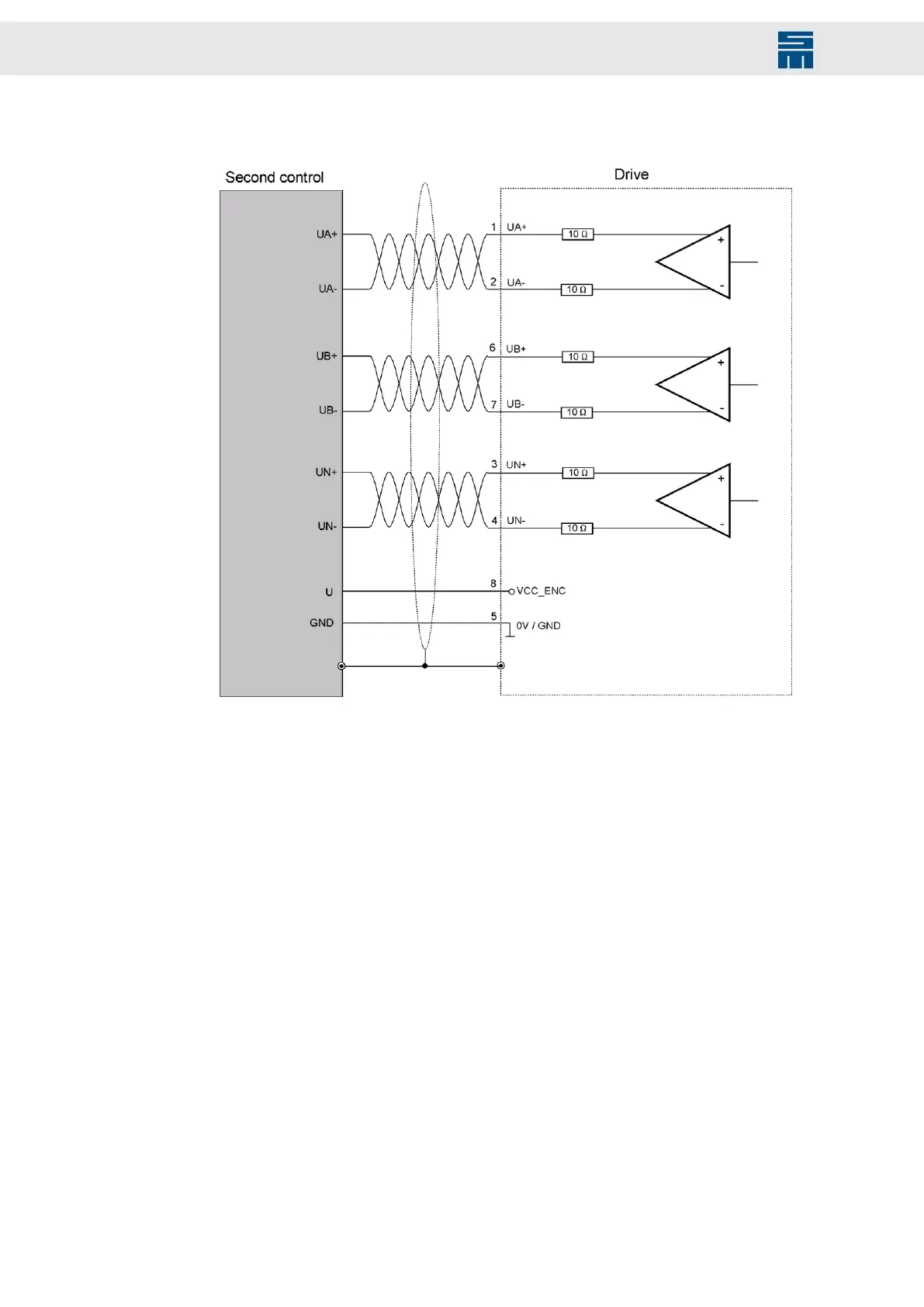

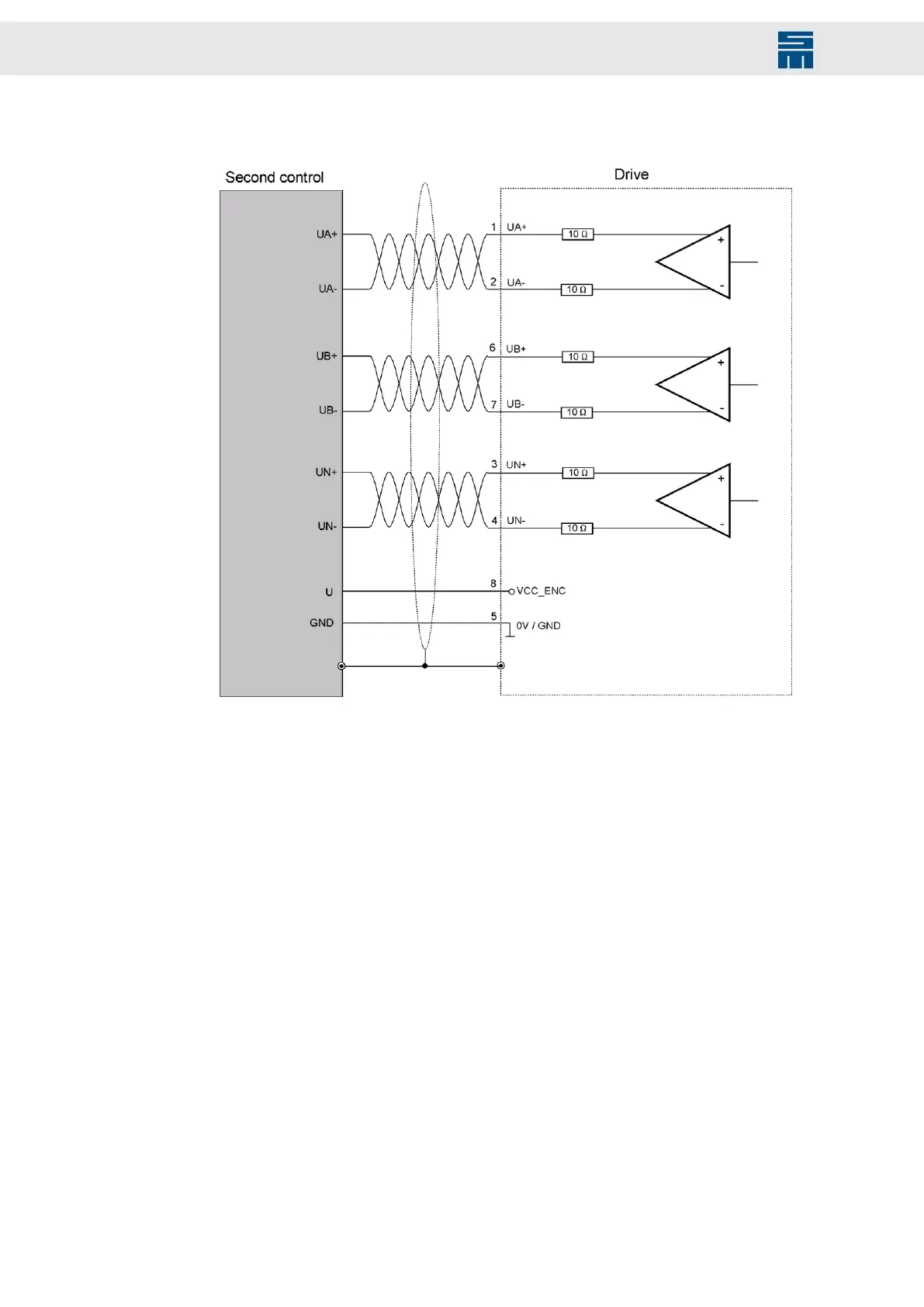

Connection Examples

8.3 X7 – Encoder Emulation

Fig. 21: Encoder Emulation

Fig. 21: Encoder Emulation

The transmission meets the requirements of the standard TIA/EIA-422-B with a voltage

differential of at least. ±0.9 V.

62 Drive System SD2M - Hardware Description 036228xxF

Loading...

Loading...