Operating Instructions 7-15 M90 Fusion Splicer

Issue 02/97 Troubleshooting and Care/Maintenance

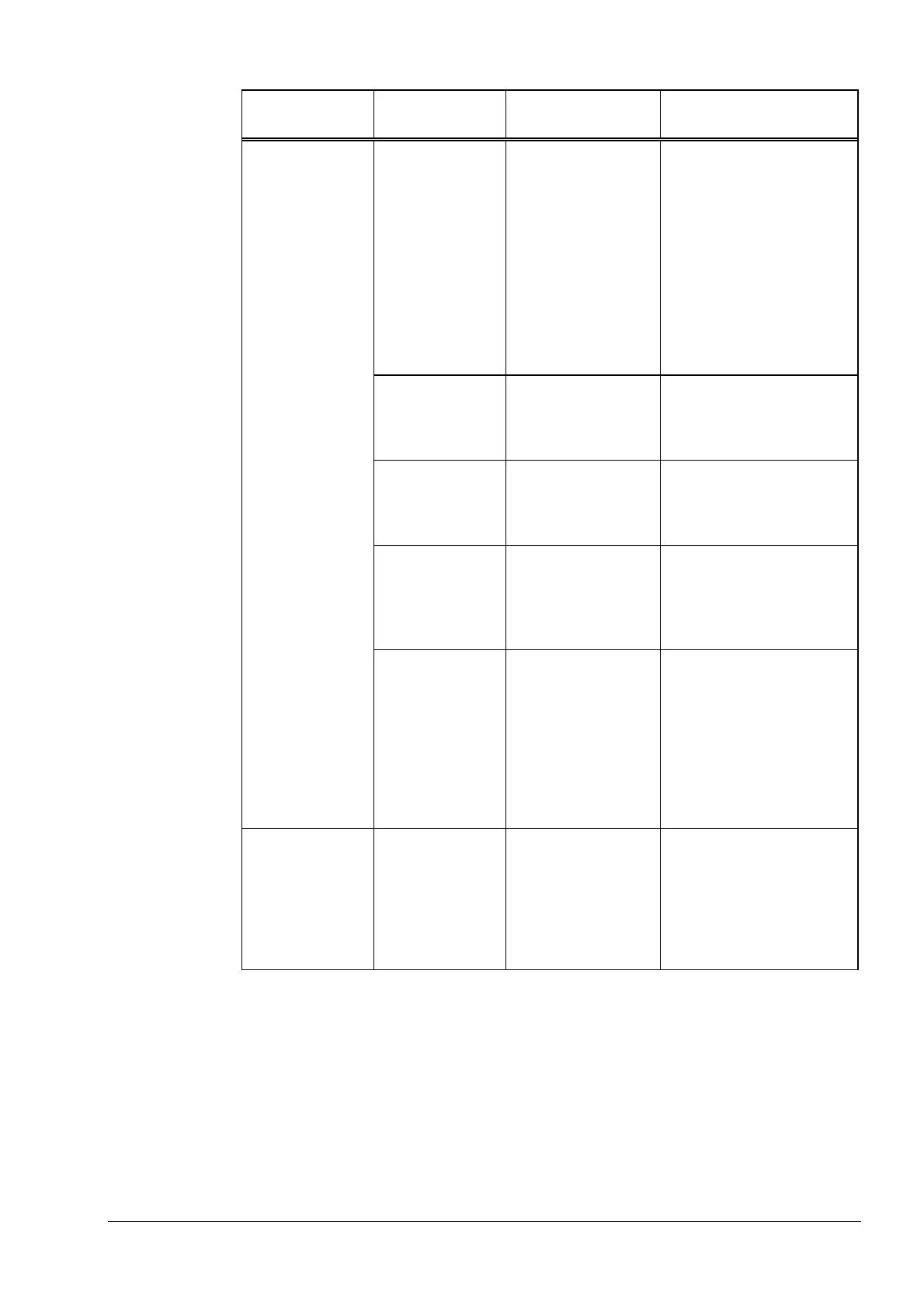

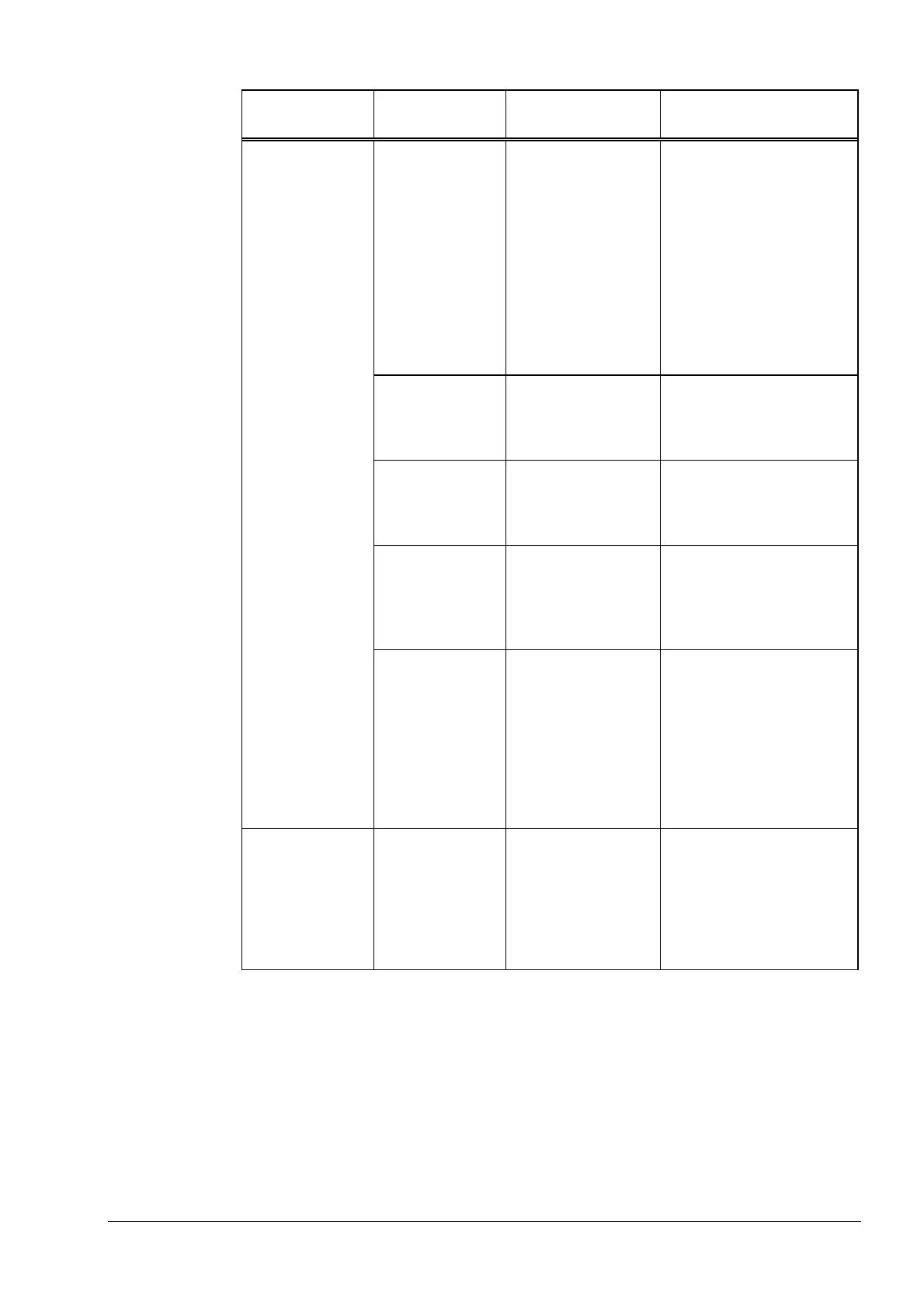

Fault Message

Fault Symptom

Possible Cause Fault Locating Remedy

Fault messages

during fiber

search and posi-

tioning

Fiber offset

excessive

(LID or video

system)

The fiber offset

before position-

ing is larger than

half the fiber

diameter

Coating stripping

edge wrongly

positioned or

fiber not located

correctly in

guide.

Check whether the

fiber is clean and

positioned correctly

in the guide.

Only 250/900 µm fiber

guide: The coating strip-

ping edge must lie inside

the mark at the end of the

fiber guide as described in

section "Preparing the

splice". In the case of

doubt, it is better that the

coating projects out of the

guide rather than the

stripping edge lies inside

the guide.

Fiber guides dirty

or damaged.

Clean the guides. Use

alcohol as solvent if nec-

essary. Exchange dam-

aged guides.

Wrong fiber

guide or wrong

cleave length.

Use the correct guide for

the fiber in question and

observe the prescribed

cleave length.

Dirt under the

fiber guides.

Remove the fiber guides,

clean them from below as

well and remove dirt from

the receiving channel in

the guides.

Positioning sys-

tem not aligned

properly.

Check the fiber po-

sition using clean

900-µm guides.

Only if the fault is

then repeated must

the positioning sys-

tem be realigned. (Is

very seldom the

case.)

Perform basic alignment of

the X/Y axis as described

below. Even if the splicer

functions correctly after-

wards, you should still

send it for examination to

the service center at the

earliest opportunity.

Fiber dirty or

damaged

The video sys-

tem has detected

that the total end

face angle ex-

ceeds 2.3° or

that the end face

is dirty.

Determine on the

monitor which fiber

end is at fault.

Prepare fibers again.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...