M90 Fusion Splicer 7-16 Operating Instructions

Troubleshooting and Care/Maintenance Issue 02/97

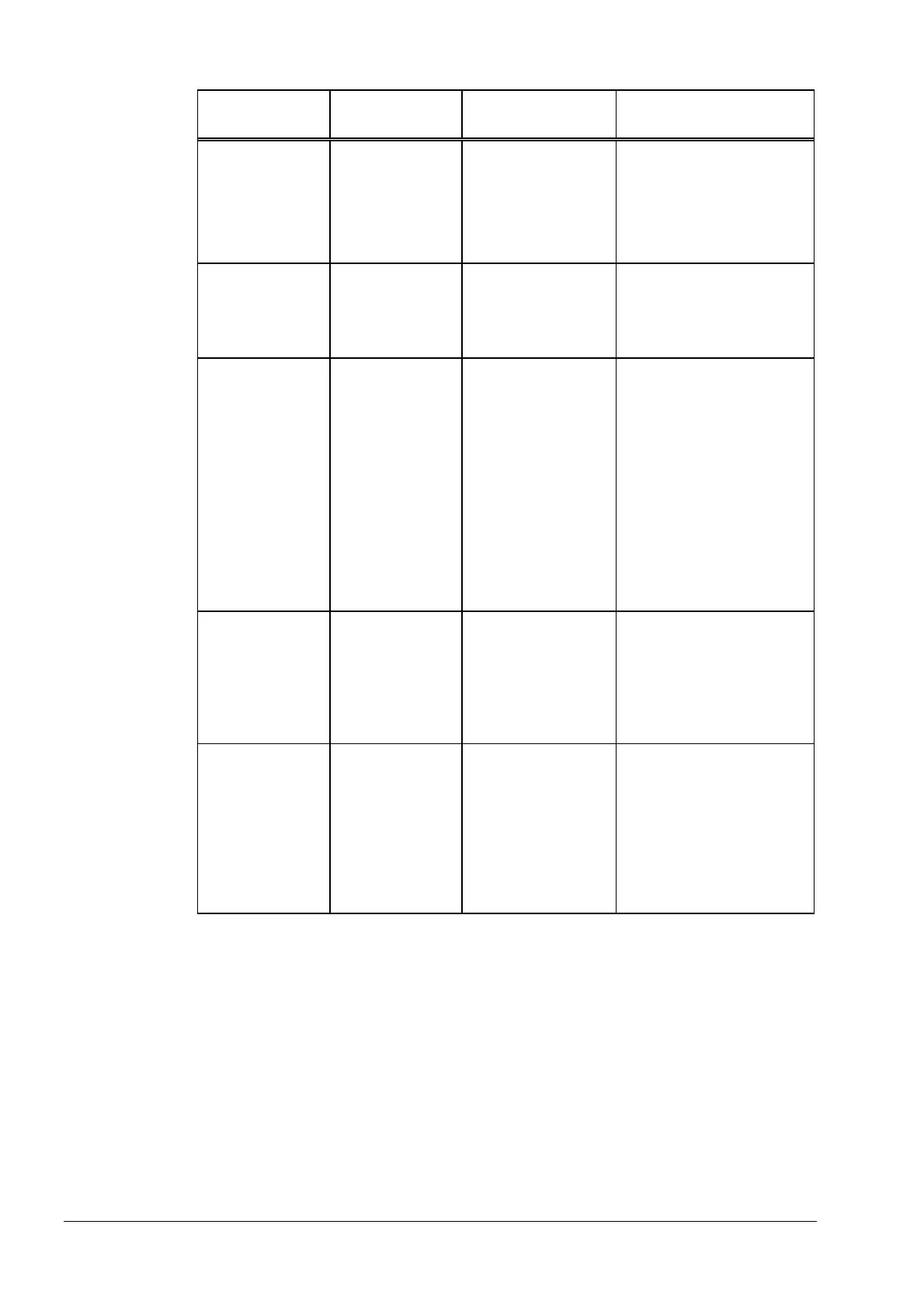

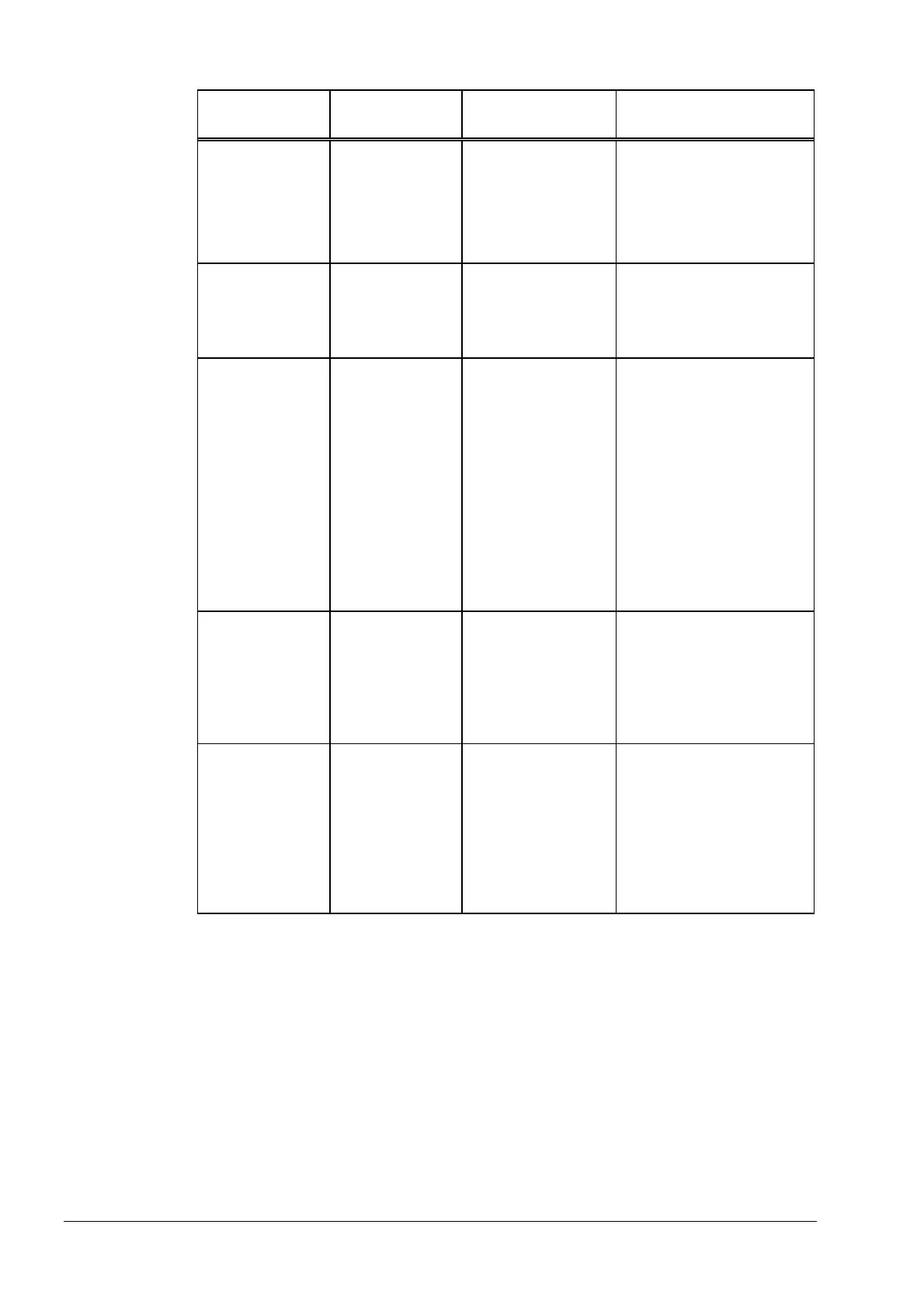

Fault Message

Fault Symptom

Possible Cause Fault Locating Remedy

Fault messages

during fiber

search and posi-

tioning

Important Inter-

fering light!

The fiber con-

tains light from a

transmission or

measuring sys-

tem or LID flaps

are open.

Switch off foreign light

source or close LID flaps.

Auto XY

Fiber o.k. ?

Fiber offset

not

too large.

XY positioning

cannot be per-

formed.

Put through the

piezo test (see page

7-9).

The splicer must be re-

paired at the service cen-

ter.

Level too low

LID receives no

light.

Check that you have

inserted the fiber

into the LID. If the

fault still occurs

select

Manual fiber

adjustment

from

the menu and check

that a minimum level

of 0.5 is displayed

when a continuous

fiber is inserted.

Clean the LID system and

ensure there is sufficient

index-matching fluid on the

input and output areas. If

the LID level is still not

high enough with a con-

tinuous fiber, the fiber is

not LID-compatible. In this

event, you can either re-

move the color from the

fiber which is inserted in

the LID or use one of the

video programs.

LID system

overdriven

Malfunction of

the LID system.

The fault can only be

eliminated by the service

center.

You can continue using

the video system, how-

ever.

Video analysis

faulty

Video system

electronics not

functioning.

Switch off the splicer and

switch it back on again. If

the fault occurs again, the

splicer must be repaired at

the service center.

You can fuse using man-

ual fiber positioning (with

or without LID).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...