Commissioning Manual

164 01/2017

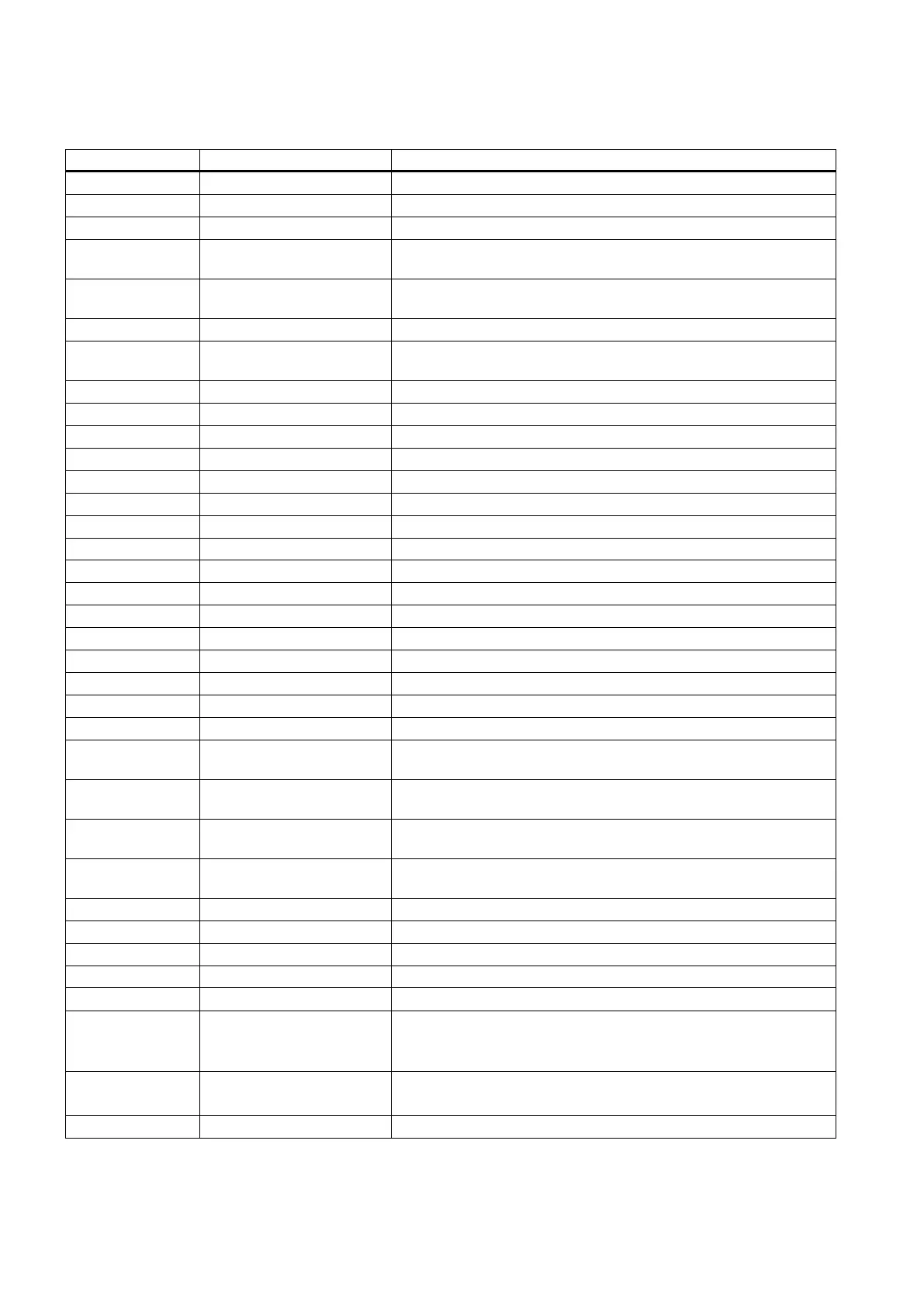

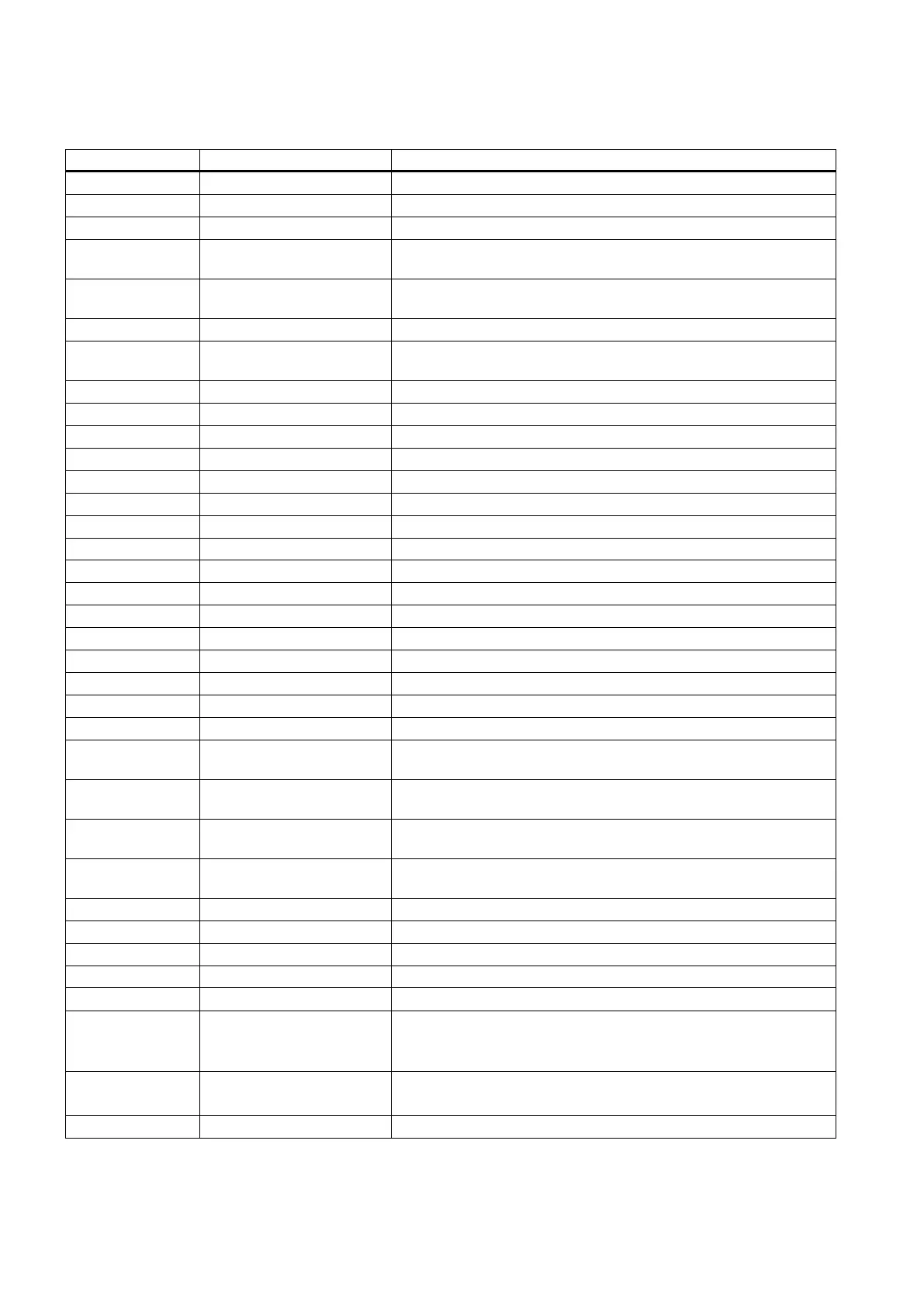

PLC sample subroutines offer PLC functions for the machine tool.

Working lamp control, called in the subroutine "AUX_MCP"

22 AUX_SAFE_DOOR Safety door control, called in the subroutine "AUX_MCP" for a milling

23 AUX_CHIP Chip conveyor control, called in the subroutine "AUX_MCP" for a

Three-color lamp control, called in the subroutine "AUX_MCP"

31 PLC_ini_USR_INI Reserved for initialization functions of the manufacturer (this subrou-

tine is automatically called by subroutine 32)

PLC initialization, executed at the first PLC cycle (SM0.1)

Signals from the MCP and HMI are sent to NCK interfaces

Display tool numbers via the 7-segment LED of the MCP

Handwheel selection via the HMI

Control of feed axis enable and spindle enable

Handwheel on hand-held unit

Spindle control, including the spindle braking function

Tool measurement in JOG mode

Coolant control (Manual Machine key and M code: M07, M08, M09)

Lubrication control (interval and time)

ASUP (Asynchronous Subroutine Program)

Automatic gear change of the spindle

Virtual gear change of the spindle

51 Turret1_HED_T Turret control for turning machine (turret type: Hall element transistor,

52 Turret2_BIN_T Turret control for turning machine (turret type: position detection with

53 Turret3_CODE_T Hydraulic turret control for turning machine (turret type: position de-

tection with encodings)

54 Turret2_3_ToolDir Evaluate tool direction and calculate tool position (called by Tur-

ret2_BIN_T, Turret3_CODE_T)

Tailstock control for turning machine

Clamp or release control for turning machine

Spindle signal processing for the manual machine

Disk tool magazine for a milling machine

62 Trg_key_OR Spindle override, feedrate override, and rapid feedrate control for a

turning application

Spindle override control for a milling application

63 TOGGLE Six key-operated switches: K1 to K6

Two delay switches: K7, K8

Loading...

Loading...