Commissioning Manual

248 01/2017

Commissioning the turret/magazine

8.1

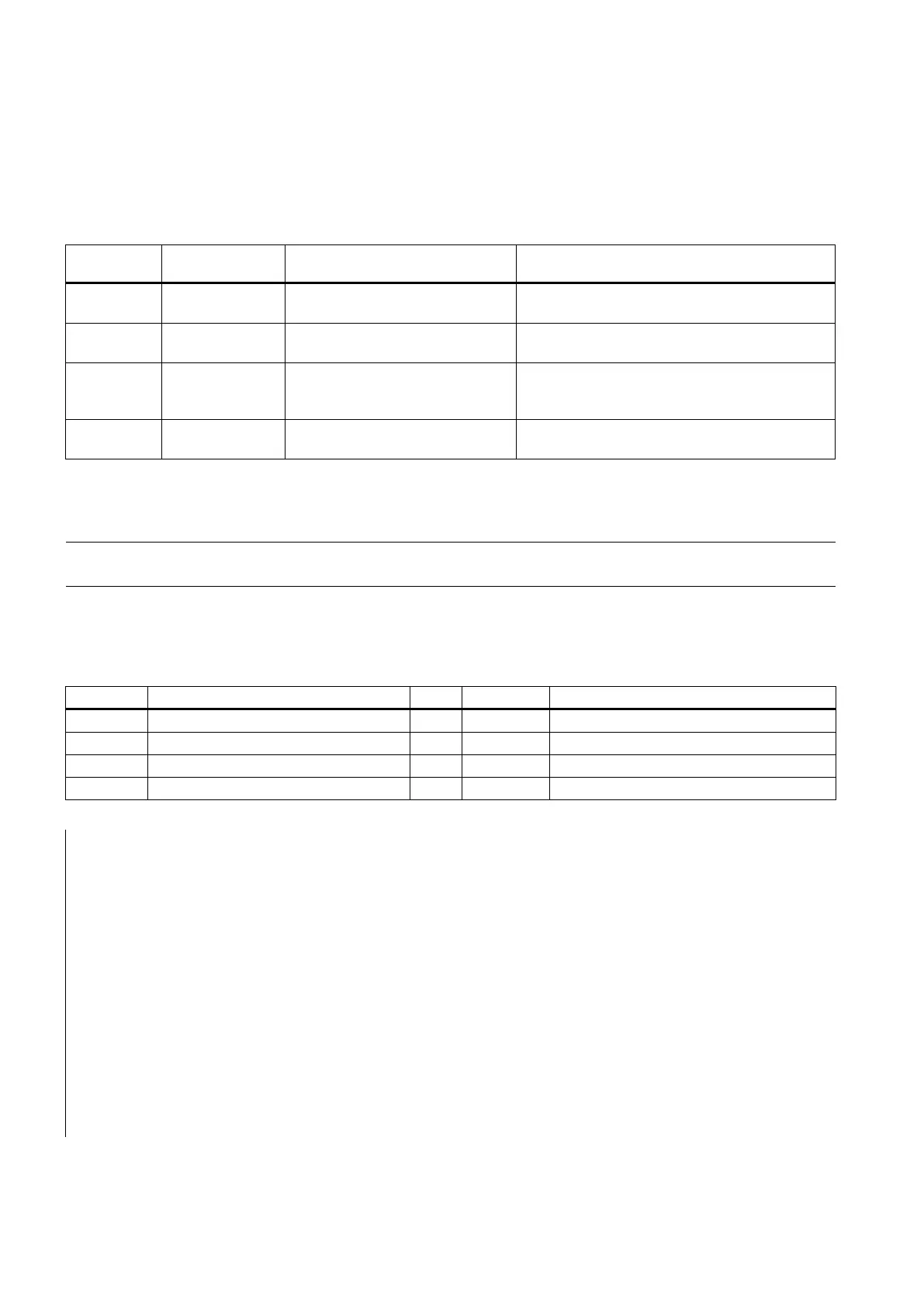

PLC subroutines for tool change

The following PLC subroutines are provided for the turret/magazine control on a turning or milling machine.

SBR 51 Turret1_HED_T HED turret control for turning ma-

Subroutine 51 - Turret1_HED_T (turret with Hall

effect device position sensor) (Page 186)

SBR 52 Turret2_BIN_T Bi-direction turret (binary coded)

control for turning machine

Subroutine 52 - Turret2_BIN_T (turret with binary

coding function) (Page 188)

SBR 53 Turret3_CODE_T Bi-direction turret (coded by turret

supplier) control for turning ma-

Subroutine 53 - Turret3_CODE_T (tool change

control for turret with coding function) (Page 190)

SBR 60 Disk_MGZ_M Disk tool magazine control for

Subroutine 60 - Disk_MGZ_M (disk-style tool

magazine used for milling) (Page 198)

Calling cycles for tool change

You can call a user cycle with "M" or "T" code to perform the tool change operations.

Note

An "M" code and a "T" code for calling user cycles must not

be in the same program block.

The following examples are given for the tool change on a milling machine.

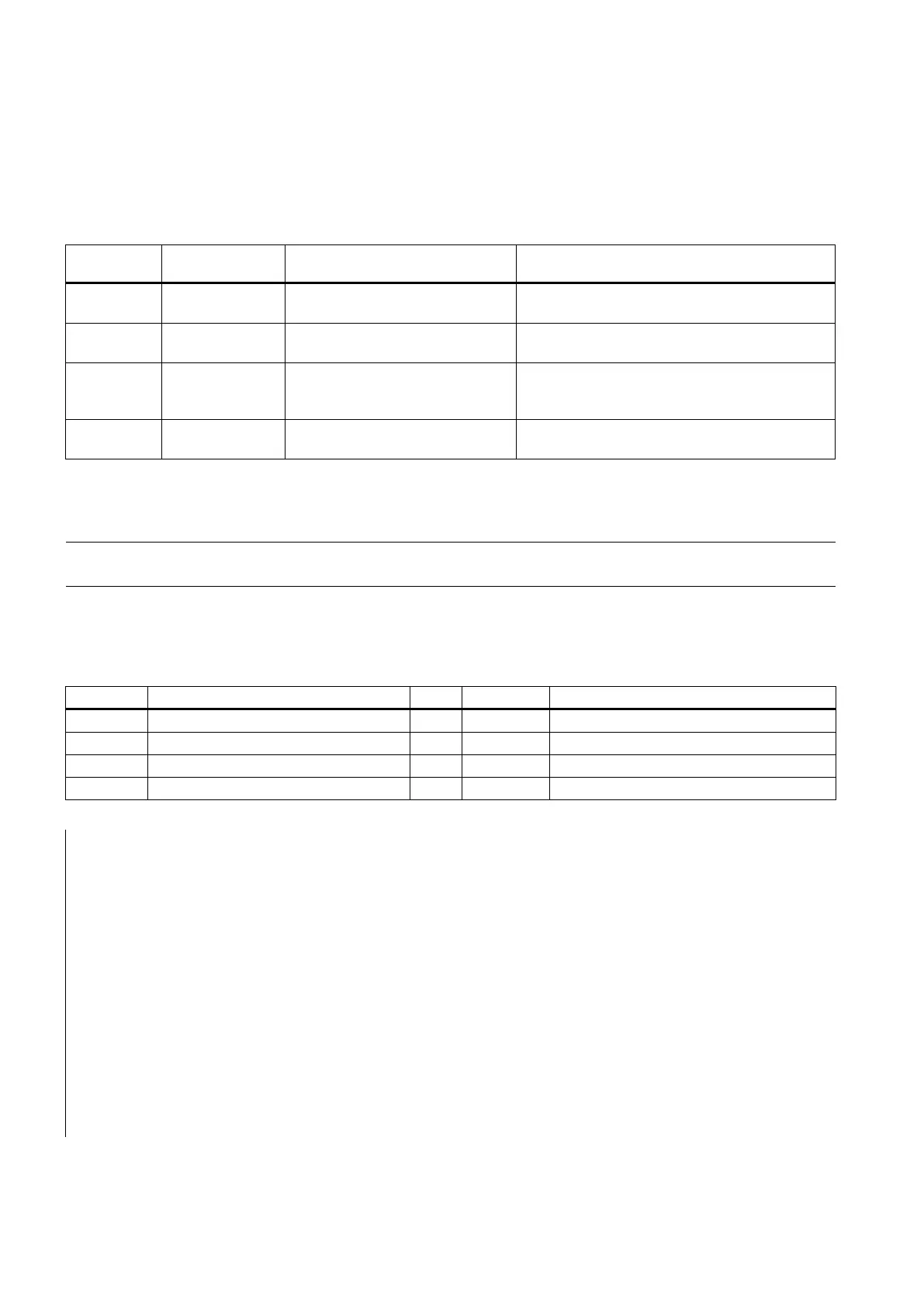

Calling a tool change cycle with "M6"

Configure the parameters shown in the table below to activate an M code for calling a standard cycle:

Activating tool parameters with an M code

The M code for activating tool parameters

Calling the standard cycle with M6

Name of the standard cycle

For the format of a standard cycle, refer to the example below:

;>>> Name of user cycle <<<

;>>> Path of user cycle <<<

;>>> Definition of user cycle <<<

;No tool change in "program test"

IF $P_SEARCH<>0 GOTOF _END

;No tool change in "program search"

IF $P_TOOLNO==$P_TOOLP GOTOF _NO

;No tool change if programmed tool ($P_TOOLP) =

currently active tool ($P_TOOLNO)

;Work offset and tool offset OFF

;Approach fixed point (tool change position) in Z

SPOS=$MN_USER_DATA_FLOAT[0]

;Spindle exact stop position is stored in

MD14514[0]

MSG("Ready to change tool *** Original tool num-

ber: T"<<$P_TOOLNO)

;A maximum of 127 characters can be displayed

;>>> User-defined M codes can be used to start the PLC logic for tool change after spindle position-

ing

;>>> PLC sets signal "Read-in disable" (DB3200.DBX6.1) to stop this standard cycle

;>>> PLC controls the action of tool magazine and turret

;>>> After the tool change, PLC resets signal "Read-in disable" to resume the cycle

;Activate tool parameters

Loading...

Loading...