Commissioning Manual

01/2017

175

Note

When using the hardware solution, you must

take below information into consideration:

You must assign the axes one by one; for example, X axis, Z axis, spindle or X axis, Y axis, Z axis, spindle. You must not

assign the axes like X axis, Y axis, spindle, Z axis.

You must set constant "1" (i.e. SM0.0) to the input signals of the hardware limits for undefined axes; otherwise, the

hardware limits of the undefined axes can be activated.

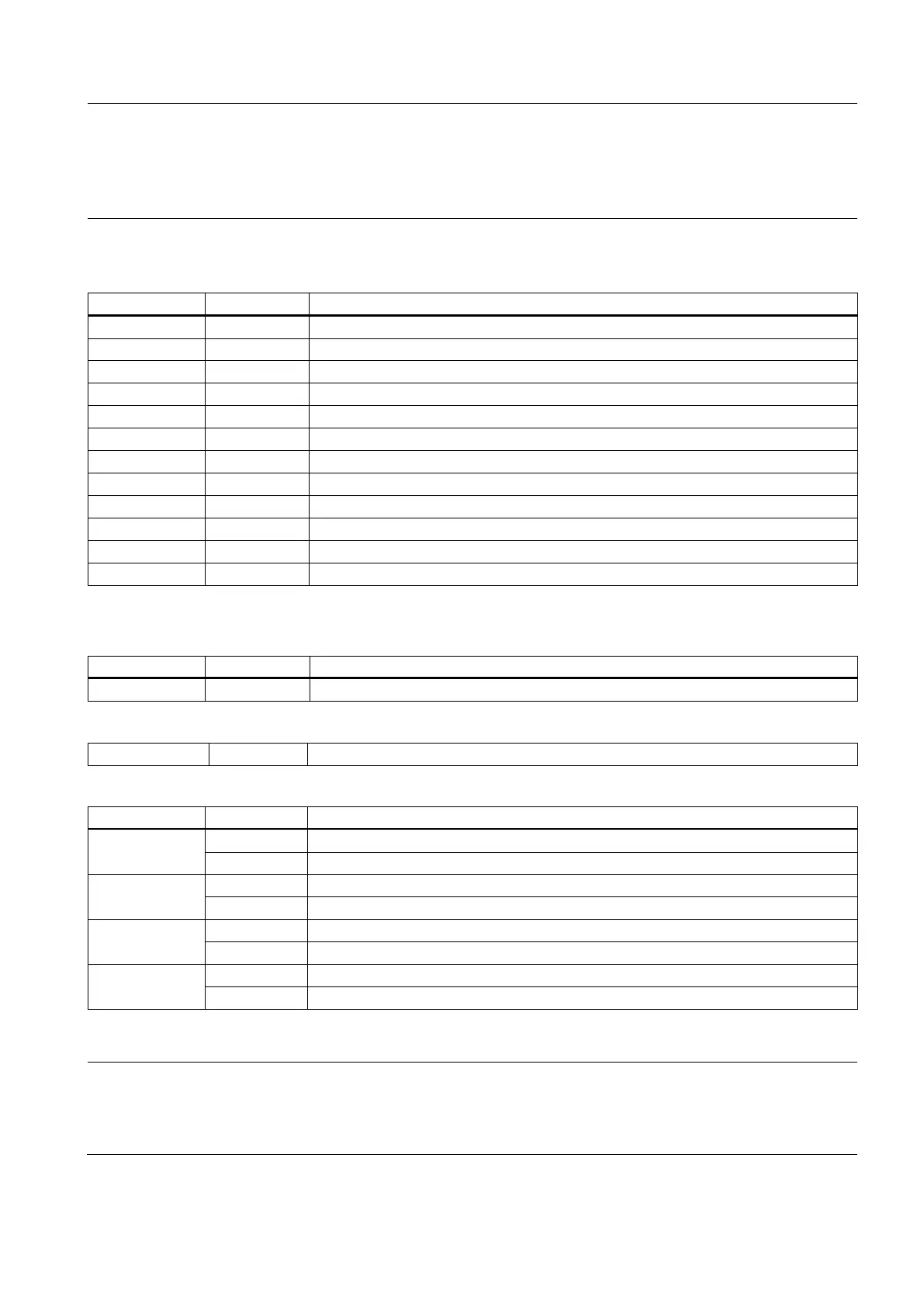

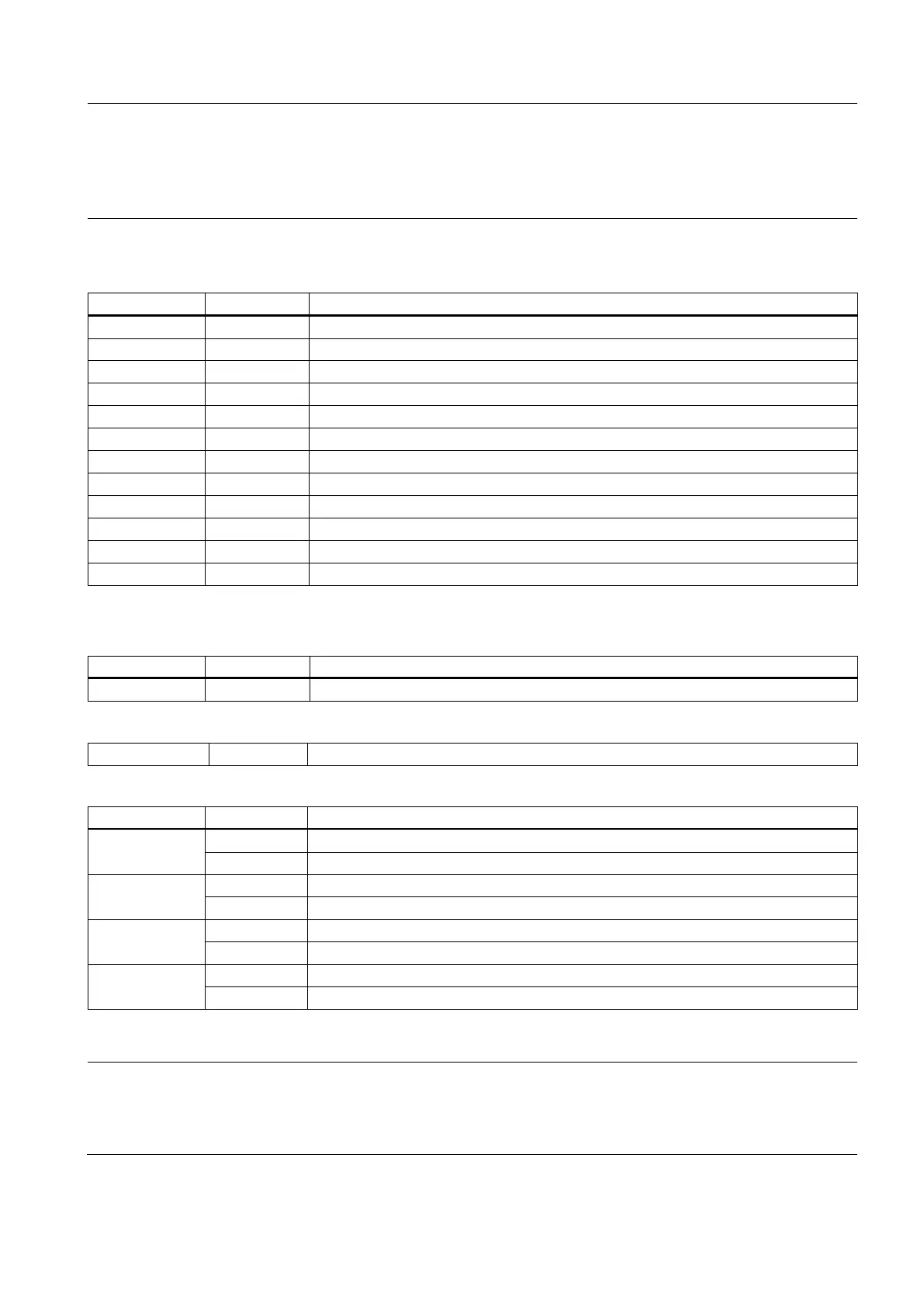

Local variable definition

Inputs

NC being in the cyclic state and able to enable the drive

Positive hardware limit switch of 1st axis (NC)

1)

Negative hardware limit switch of 1st axis (NC)

Reference cam of 1st axis (NO)

Positive hardware limit switch of 2nd axis (NC)

1)

Negative hardware limit switch of 2nd axis (NC)

Reference cam of 2nd axis (NO)

Positive hardware limit switch of 3rd axis (NC)

1)

Negative hardware limit switch of 3rd axis (NC)

Reference cam of 3rd axis (NO)

_5REF BOOL Reference Cam of 5th axis (NO)

1)

The hardware limit + is used for the input if there is only one hardware limit switch or when the hardware solution is

used.

Any of the axis over hardware limits

Assigned global variables

Spindle start command (CW or CCW)

Relevant PLC machine data

14512 [18].6

Overtravel employs the hardware solution

Overtravel employs the PLC solution

14512 [18].7

Each axis has only one hardware limit switch

Each axis direction has an hardware limit switch

14512 [20].1

Disable by pressing the spindle stop key

Disable when detecting the standstill speed

1)

14512 [21].1

Set I0.0 to I2.7/Q0.0 to Q1.7 as the standard I/O wiring in the default PLC

Set I6.0 to I8.7/Q4.0 to Q5.7 as the standard I/O wiring in the default PLC

1)

When setting bit 1 to 1, make sure that the speed control mode is active.

Note

By default, the value of MD30350 is 0

,

indicating that the NC will run in the real axis mode. When performing the axis control

related operations on a stand

-alone controller without any connection to the motor or drive, you need to set MD30350 to

for each axis, which indicates that the axis w

ill run in the simulated state and thus the PLC will not detect the drive ready

signal; otherwise, an alarm will be thrown out, indicating axis enable missing.

Loading...

Loading...