1.1 MAIN CHARACTERISTICS

• Movements

The2axes(X-Y)moveonballscrewsactivatedbystepmotorsonrectiedrollerguidesandballbushes.

• Clamp

Standardfour-sidedclamp,speciallydesignedtogripmostatkeys.

• Working tools

Consists of a cutter in hard metal (carbide), that is easily replaced. Suitable to the type of work and speed rotation

needed.

• Display

Rear-illuminated and placed on the front of the machine.

Display with 4 rows of 20 characters each.

Its technical features and positioning make it highly practical in use.

• Laser reader

Designed to read cuts on keys to be reproduced

.

LOADER UNIT - OPTIONAL

• Automatic Clamp

Only for keys as in Fig. 6.

• Loader

Only for keys as in Fig. 6.

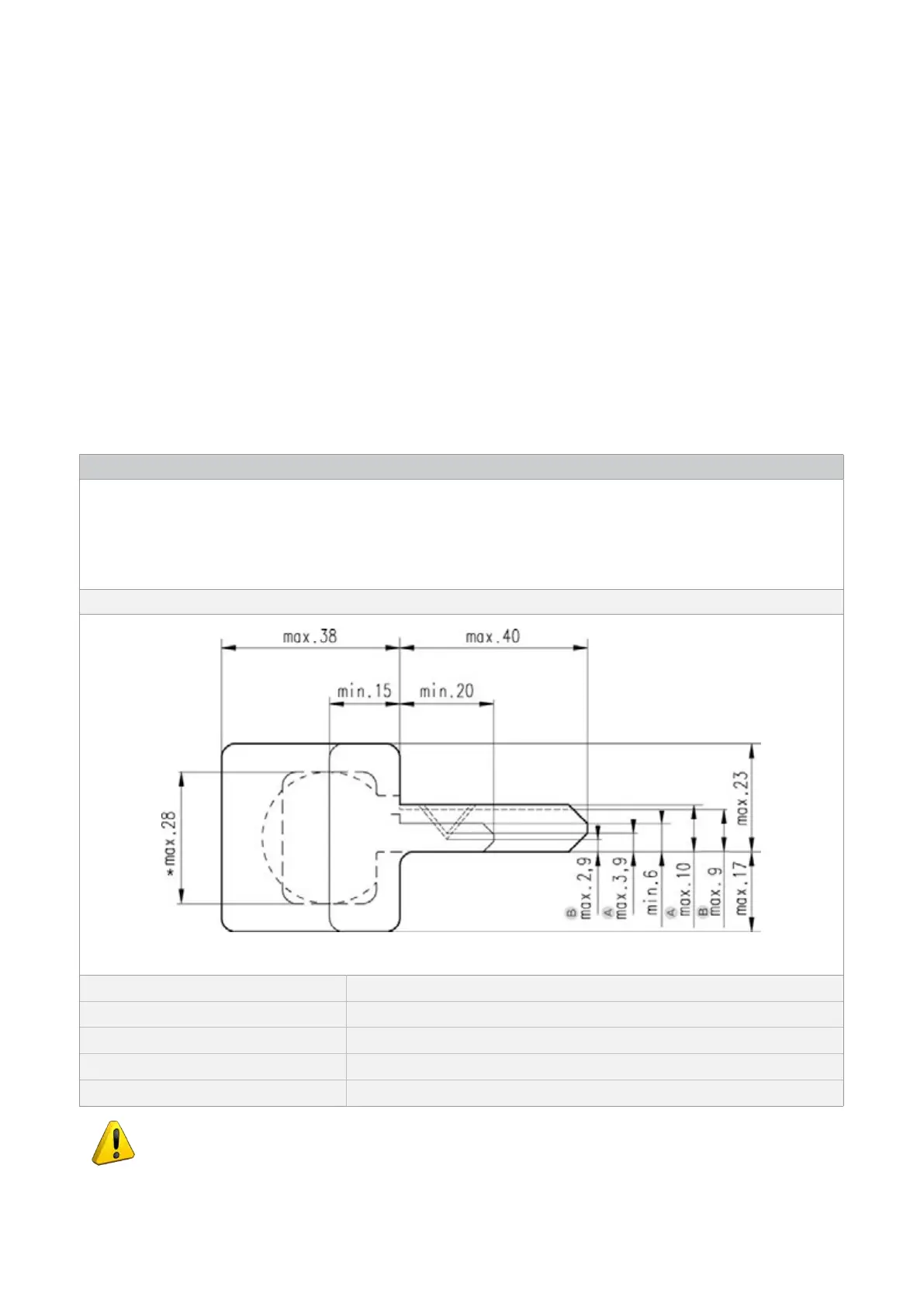

TECHNICAL DATA FOR KEYS TO BE CUT WITH OPTIONAL FEEDER

Fig. 6

Key thickness: min.1,8 mm - max.2,6 mm (with jaws A o B)

min. 2,0 mm - max.2,8 mm (with jaws A + 2,0÷2,8)

Max. cutting depth: 3,9 mm (with jaws A); 2,9 mm (with jaws B)

Blade height/width: max.10 mm (with jaws A); max.9 mm (with jaws B)

Key head width: *max. 28 mm

ATTENTION: only for keys with cuts on 1 side and key stop [not keys with plastic heads

(except for SWING and SILKY), not cruciform keys or keys with tip stops].

Operating Manual UC199

Copyright Silca 2012

5

Loading...

Loading...