5.8.2 MACHINE ZEROES

The machine is pre-arranged for a partial “self-setting” system by means of templates provided (Ch. 1.6) and

specicprocedures.Theseproceduresmustbecarefullycarriedoutfollowingthedescriptionsandillustrations

indicated below.

EVENT

MACHINE

ZEROES

CALIBRATIONS

STANDARD

CLAMPS

AUTMATIC

CLAMP

Electronic board replacement

NO YES YES

Replacement of the Optical Reader unit

NO YES YES

Replacement sensors

YES YES YES

Replacement of the cutter shaft (*)

YES YES YES

Replacement of the ball screws (*)

YES YES YES

(*) Only from Silca S.p.A. or Silca Authorized After-Sales Service Centres.

2 – MACHINE ZEROES

NOTE: this operation is possible only with standard 4 sided clamps.

NOTE: If the machine has an optional feeder unit installed, proceed as follows (see Ch. 5.8.3):

1) Remove the Automatic Clamp: loosen the screw (D2) and pull out the clamp to the left.

2) Remove the Loader: possible only after having removed the automatic clamp; loosen the screw (D3) and pull

out the loader.

NOTE: the machine is used without the loader unit, remember to insert the serial protection (S1) into

the special loader seat, then t the standard cutting clamp into the special dovetail runner and push

all the way in to the right. Tighten the screw (D2).

With the pointer on position 2 - press ENTER

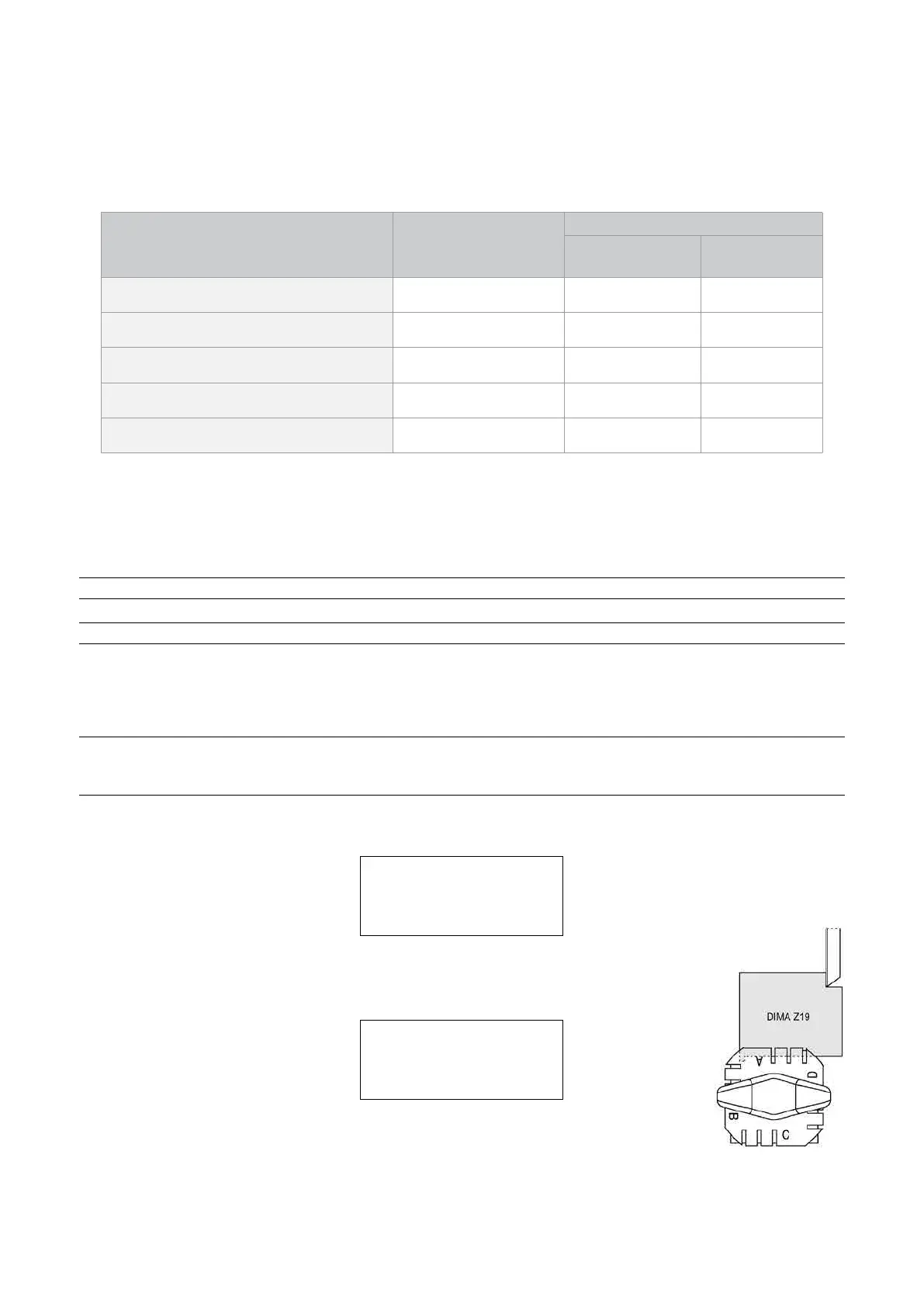

Install Z19 template

cutting side

See operating manual.

[ENTER]

-

tthetemplateZ19onsideAintotheL100Standardclamp(cuttingside).

-

press ENTER, the display will show:

Move axis up until

contact is made.

See operating manual.

[ENTER]

Move the X and Y carriages by hand, to take the template Z19 up against the cutter to make

contact with the side and front (Fig. 62).

Fig. 62

cutter

clamp cutter side

Operating Manual UC199

Copyright Silca 2012

56

Loading...

Loading...