133

SJ6826RT, SJ6832RT

213560ABA

General Section 5 – Procedures

5.2-4 Wheel Bolt / Nut Inspection and

Torquing Procedure

It is necessary to check the torque on all wheel

nuts and wheel bolts at pre-delivery, after 8 hours of

operation and at weekly intervals using the following

procedure:

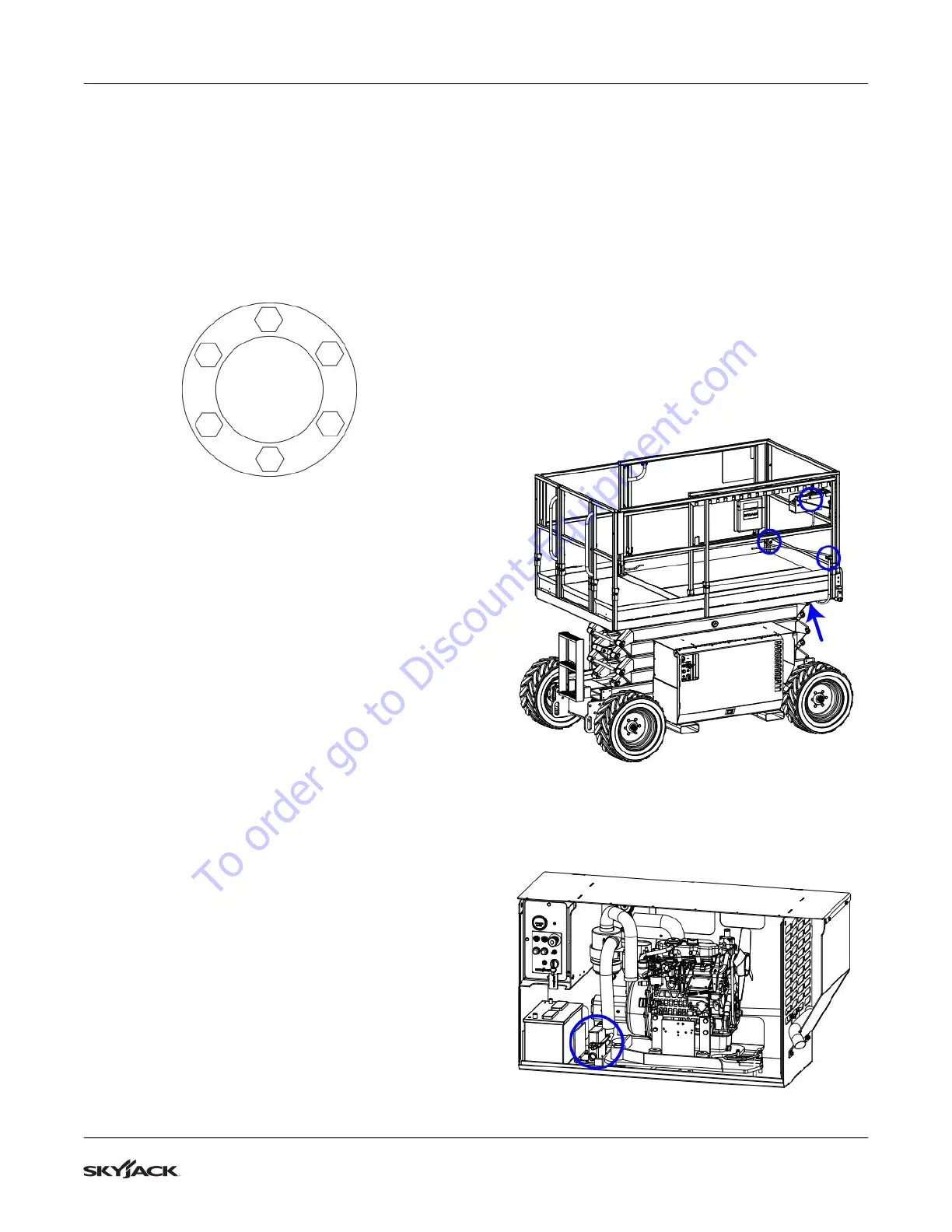

1. Conrm that each wheel fastener is torqued to

90 ±5 ft•lb. All fasteners must be torqued using

the tightening sequence below.

1

6

4

2

5

3

2. Re-torque as necessary until all fasteners are

properly torqued.

5.2-5 Wheel Reinstallation and Torquing

Procedure

When a Wheel/Tire Assembly has been removed or

replaced, it will be necessary to follow the procedure

below to ensure proper installation:

1. Inspect wheel fastener threads for damage and

defects. Replace if defective.

2. Clean the mounting surfaces of hub and the

wheel rim of debris, rust, excess paint, etc.

3. Mount wheel on the hub, centering mounting

holes on the wheel studs or bolt holes. Use

appropriate lifting device as required.

4. Install wheel nuts or wheel bolts and hand

tighten to center the rim.

5. Tighten nuts or bolts to approximately

50 ft•lb torque using the tightening sequence

shown above.

6. Tighten to 90 ft•lb using the same sequence.

7. Repeat the torque sequence to conrm that

none have changed from 90 ft•lb. If any are

found below 90 ft•lb, repeat complete sequence

until there is no change in torque values. If

possible, drive the machine prior to checking

torques.

8. Check torque values after 8 hours of operation

and then at weekly intervals.

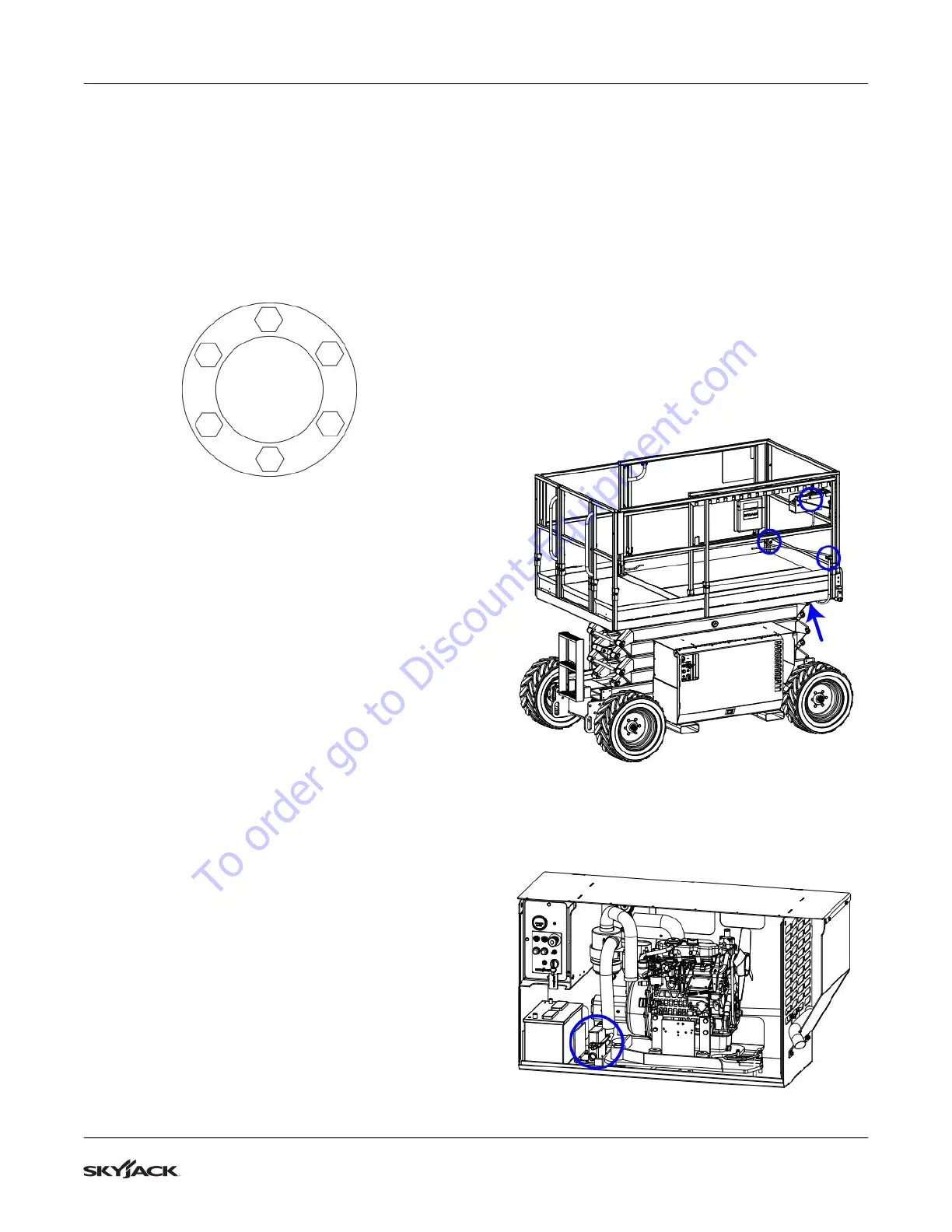

5.2-6 Reconnecting the Platform Control

Box for Use from the Ground

1. To facilitate servicing the aerial platform, the

platform control box may be removed from the

platform, and reconnected inside the hydraulic

cabinet, to allow functions to be accessed from

the ground.

2. From the platform, remove the quick release

pins securing the platform control box to the

control box mount and cable guides.

3. Disconnect the control box cable from the

scissor control cable (swing down the small

latch on the side of the connector and pull the

connectors apart). The connectors are located

near the front right corner of the platform on the

underside.

4. Bring the control box down from the platform to

the ground.

5. Locate the control cable connectors inside the

engine cabinet.

To order go to Discount-Equipment.com

Loading...

Loading...