25

SJ6826RT, SJ6832RT

213560ABA

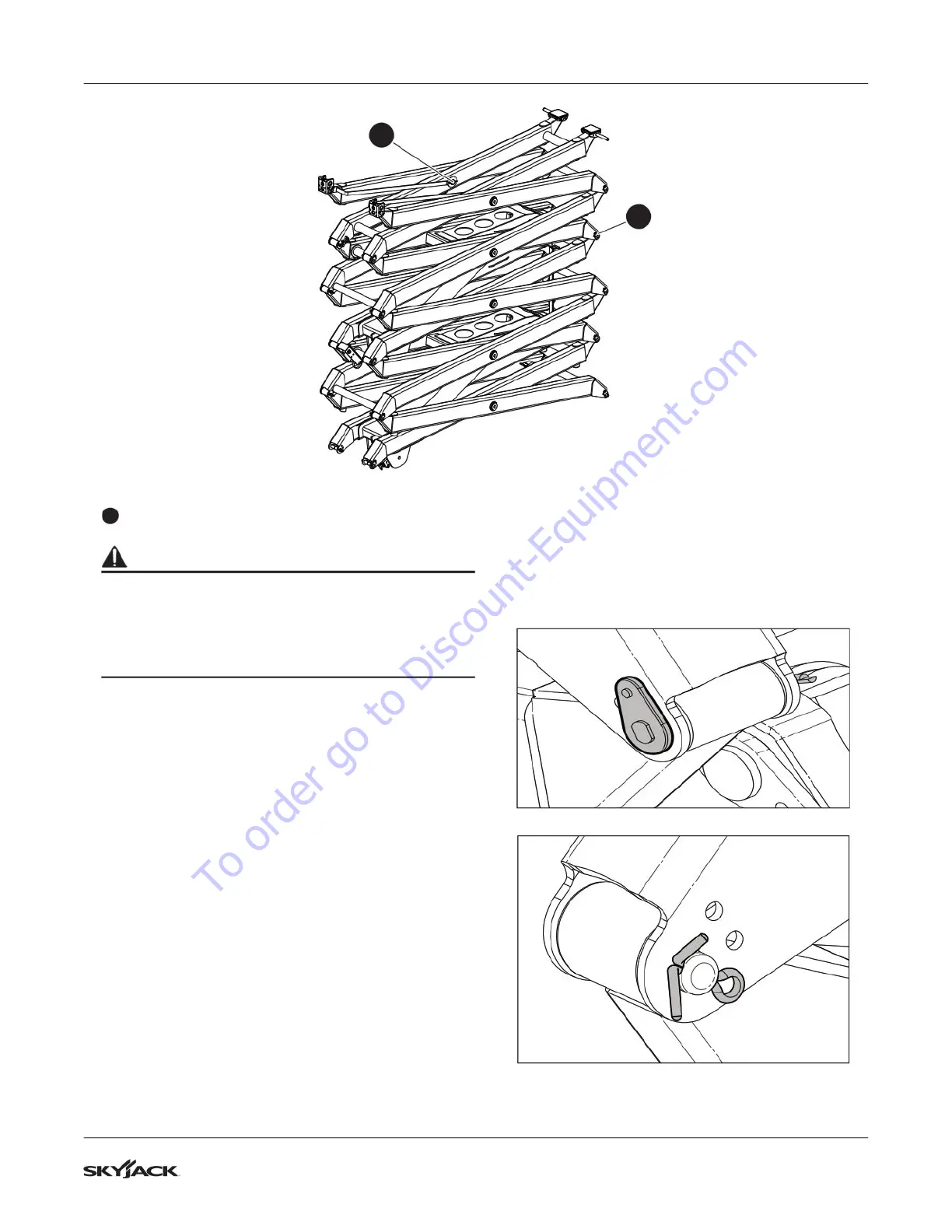

Scissors inspection Section 1 – Scheduled Maintenance

6

Scissor pin inspection (B)

WARNING

Units that show signs of damage must be

immediately removed from service and repaired

by a qualied technician. Speak to the Skyjack

service department for directions on how to repair

the unit.

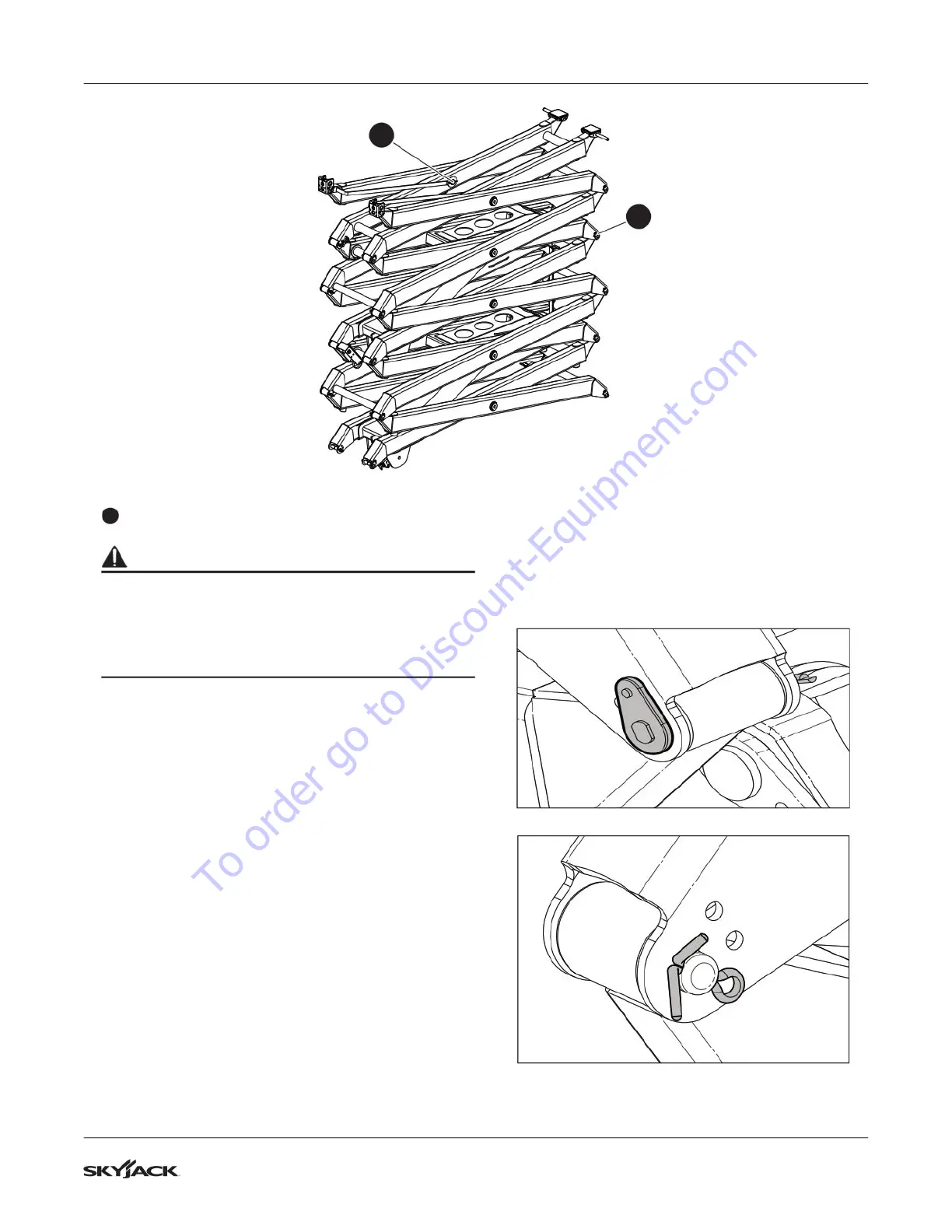

1. Do an inspection of the scissor pin connections.

Look for signs of damage on the pins and scissor

arms. These signs can include:

▪ Noise can be heard from seized pins.

▪ Rust near the pin joint

▪ Cracks in welds of adjacent metals

▪ Dust or metal shaving from worn components

▪ Broken or missing pin retainer bolts

▪ Broken or missing pin retainers

▪ Rotated pin

▪ Elongated or enlarged pin hole

2. Remove damaged pins and bushings. Do an

inspection of the scissor bore after removing the

applicable pins and bushings. Look for signs of

damage, elongation and ovality of the hole.

3. If there is no structural damage to the scissor

arms, replace the pins and bushings with new

components.

Examples of pivot pin connections with no damage:

▪ No rust

▪ Pin has not rotated

▪ Area is clear of dust or metal shavings

▪ Pin retainers are installed

6

6

To order go to Discount-Equipment.com

Loading...

Loading...