10 | Connection STOBER

116

02/2019 | ID 442728.05

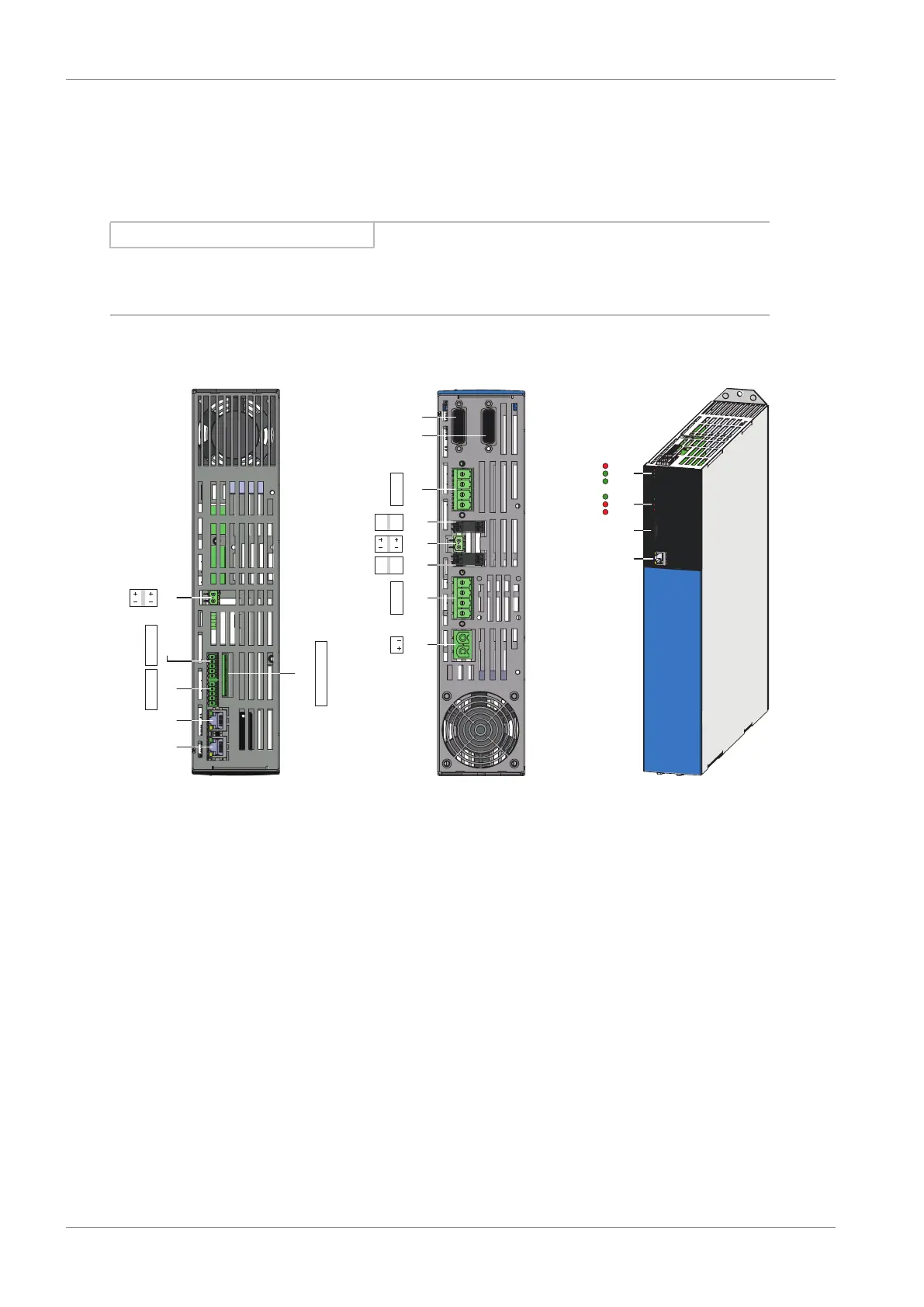

10.5 Drive controller

The following section contains detailed information about the terminals and the correct

connection of the drive controller.

Information

For UL-compliant operation: The connections marked with PE are intended solely for the

functional grounding.

10.5.1 Overview

1

3

2

4

5

7

6

8

5

3

4

2

1

X12

X103

X101

2

1

4

5

6

3

15

17

18

16

11

14

9

10

12

13

86

5

7

X22

X20A

X2A

X2B

X20B

8

7

7

8

D

D

X201

X200

X4A

X4B

PE

V

W

U

PE

V

W

U

5

3

4

2

1

6

5

X700

X9

X11

X300

Fig.30: Connection overview using the example of the SI6A162

Top of the device Bottom of the device Front of the device

1 X11: 24V

DC

supply 7 X4B: Encoder B (only for

double-axis controllers)

15 3 diagnostic

LEDs for communication

and safety technology

2 X103: BE6 – BE9 8 X4A: Encoder A 16 3 diagnostic LEDs for

drive controller

3 X12: STO via terminals

(only for SR6 option)

9 X20B: Motor B (only for double-

axis controllers)

17 X700: SD slot

4 X101: BE1 – BE4 10 X2B: Brake B (pin 5/6)

andtemperature sensor B (pin

7/8); (only for double-axis

controllers)

18 X9: Ethernet service

interface

5 X201: EtherCAT Out/

PROFINET

11 X300: Brake 24V

DC

supply

6 X200: EtherCAT In/

PROFINET

12 X2A: Brake A (pin 5/6)

andtemperature sensor A (pin

7/8)

13 X20A: Motor A

14 X22: DC link connection

Loading...

Loading...