STOBER 12 | Diagnostics

05/2019 | ID 442790.01

167

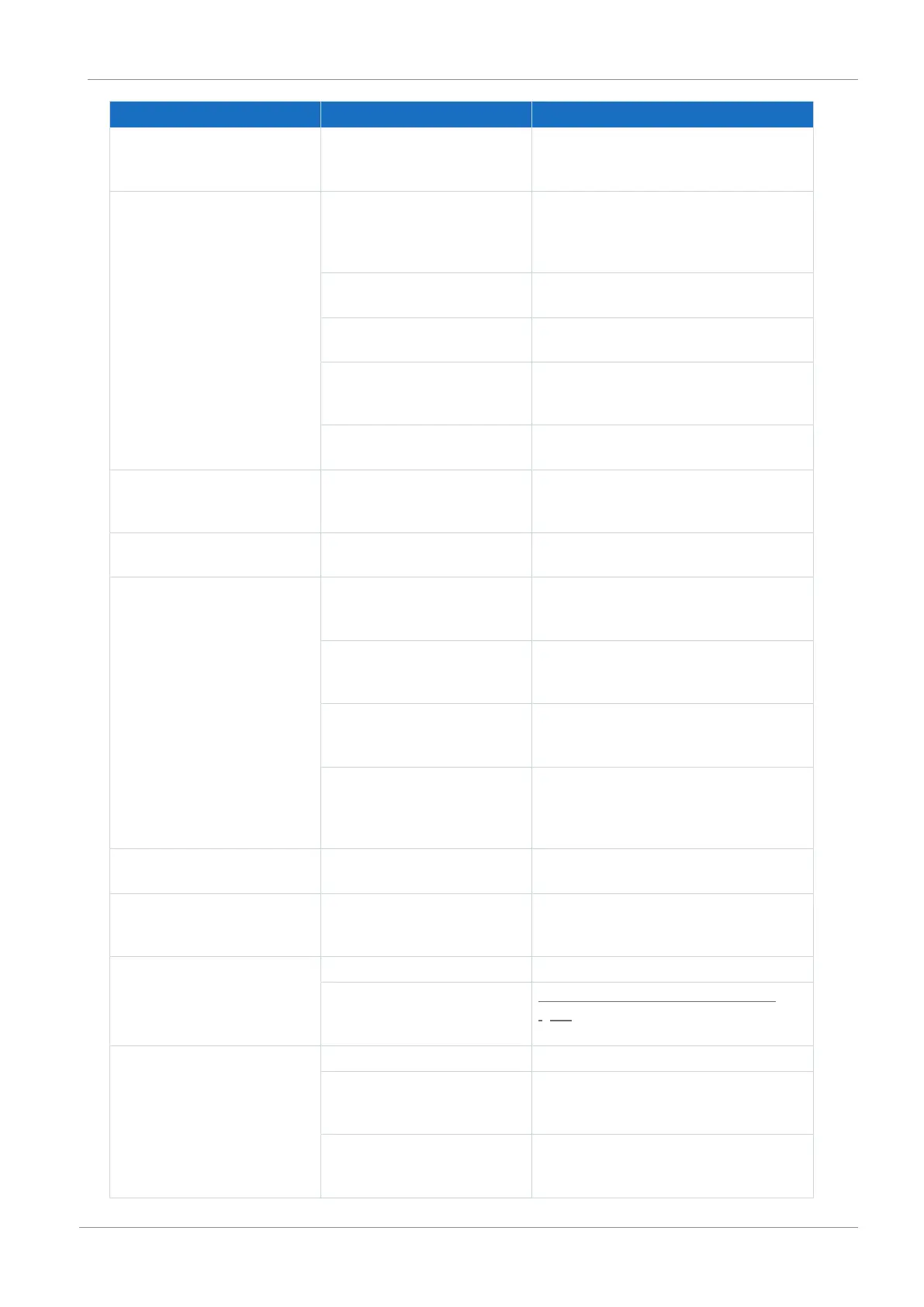

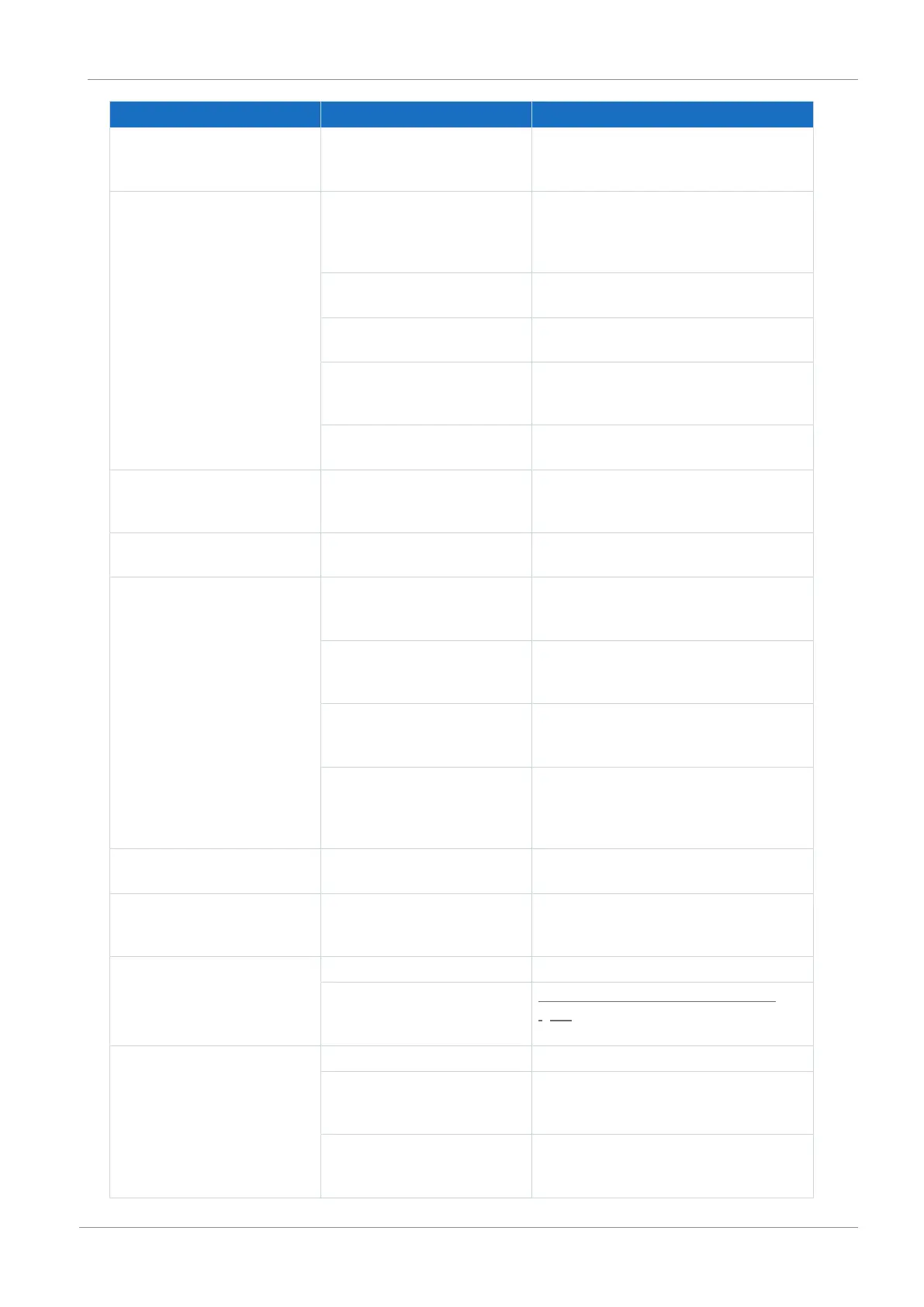

Number Cause Check and action

1: Parameter <-> encoder Inconsistent parameterization Compare the specification of the connected

encoder to the corresponding values of the H

parameters and correct them if necessary

2: X4 speed Exceeded encoder maximum

velocity

Check the actual velocity during a movement

using the scope image (E15) and adjust the

permitted encoder maximum velocity if

necessary (B297)

Connection error Check the connection and shielding and correct

them if necessary

Dynamic set values for the Lean

motor

Check the dynamics of the application set

values and reduce them if necessary

Dynamic control of the Lean motor Check the control settings; if necessary, reduce

the gain (C31, I20) and increase the adjustment

times (C32)

Toggling the Lean motor position

determination models

Check the switchover filter time constant and

increase it if necessary (B137)

6: X4 EnDat encoder found Inconsistent parameterization Compare the connected encoder to the

parameterized encoder and correct it if

necessary (H00)

7: X4 channel A/incremental Connection error Check the connection and correct it if

necessary

8: X4 no encoder found Connection error Check the connection and correct it if

necessary; restart the drive controller to switch

the encoder supply back on

Defective encoder cable Check the cable and replace it if necessary;

restart the drive controller to switch the

encoder supply back on

Defective power supply Check the encoder power supply and correct it

if necessary; restart the drive controller to

switch the encoder supply back on

Inconsistent parameterization Compare the connected encoder to the

parameterized encoder and correct it if

necessary (H00); restart the drive controller to

switch encoder supply back on

9: Reference failed Reference set for inactive Lean

motor position determination

Check device status (E48) and, if necessary,

activate the enable signal

10: X4 channel A/Clk

–

11: X4 channel B/Dat

Defective encoder cable Check the cable and replace it if necessary

14: X4 EnDat CRC

–

15: X4 double transmission

Connection error Check the connection and correct it if necessary

Electromagnetic interference Take EMC recommendations into account

[}78] and, if necessary, increase the fault

tolerance (I298)

16: X4 busy Defective encoder cable Check the cable and replace it if necessary

Inconsistent parameterization Compare the connected encoder to the

parameterized encoder and correct it if

necessary (H00)

Incompatible encoder Compare the specification of the encoder with

the corresponding specifications from STOBER

and replace the encoder or motor if necessary

Loading...

Loading...