SYSTEM SETUP

Confi guring Secondary Analog Inputs

FMS-1650

TRIATEK reserves the right to change product specifications without notice.

- 23 -

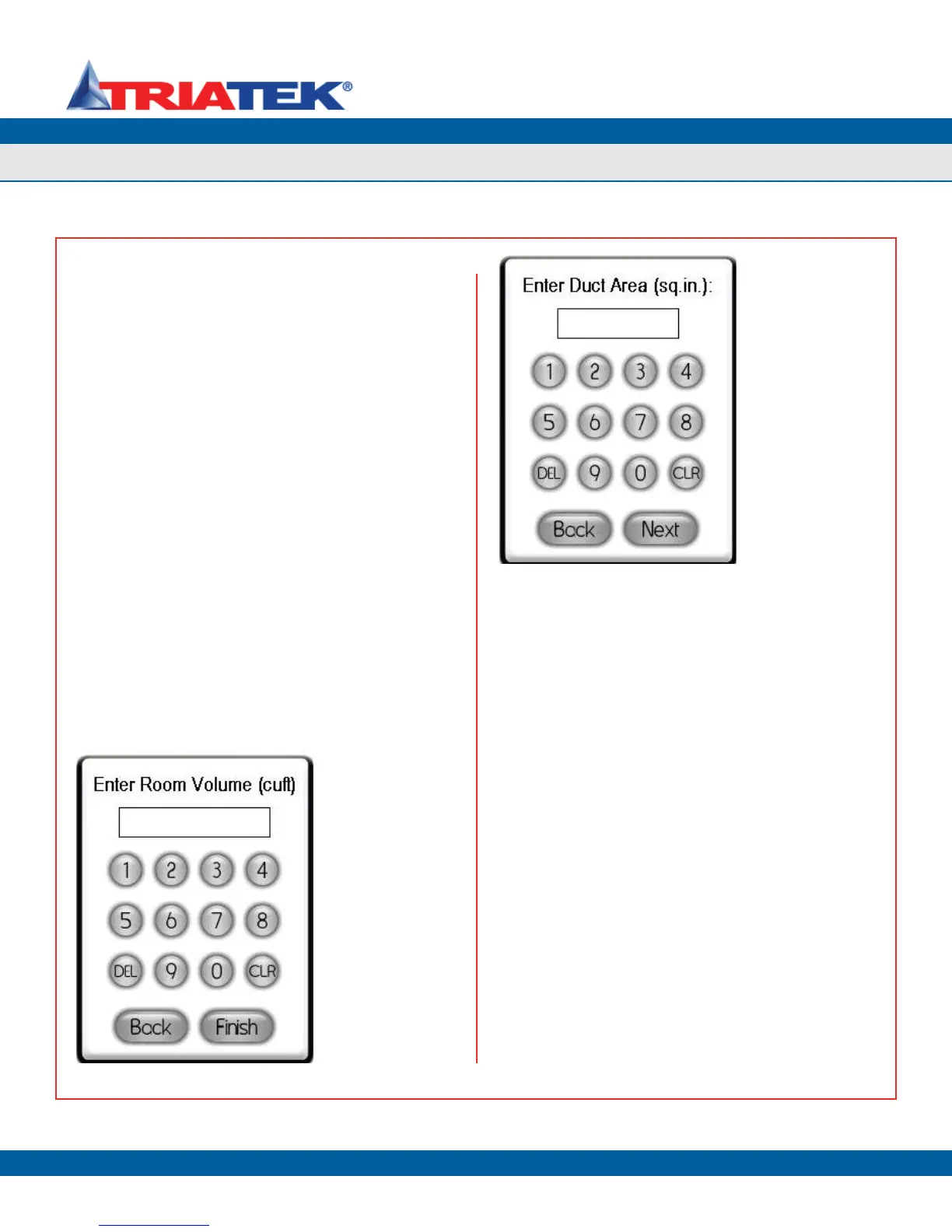

After specifying the duct cross-sectional area, click the Next button

to specify a K-factor for the specific sensor being used to input flow.

The default value for this K-factor is 1.0, but may be provided by the

manufacturer of the sensor to serve as a correction factor for the actual

output of that particular sensor unit. If no K-factor is available, this

value should be left at the default of 1.0.

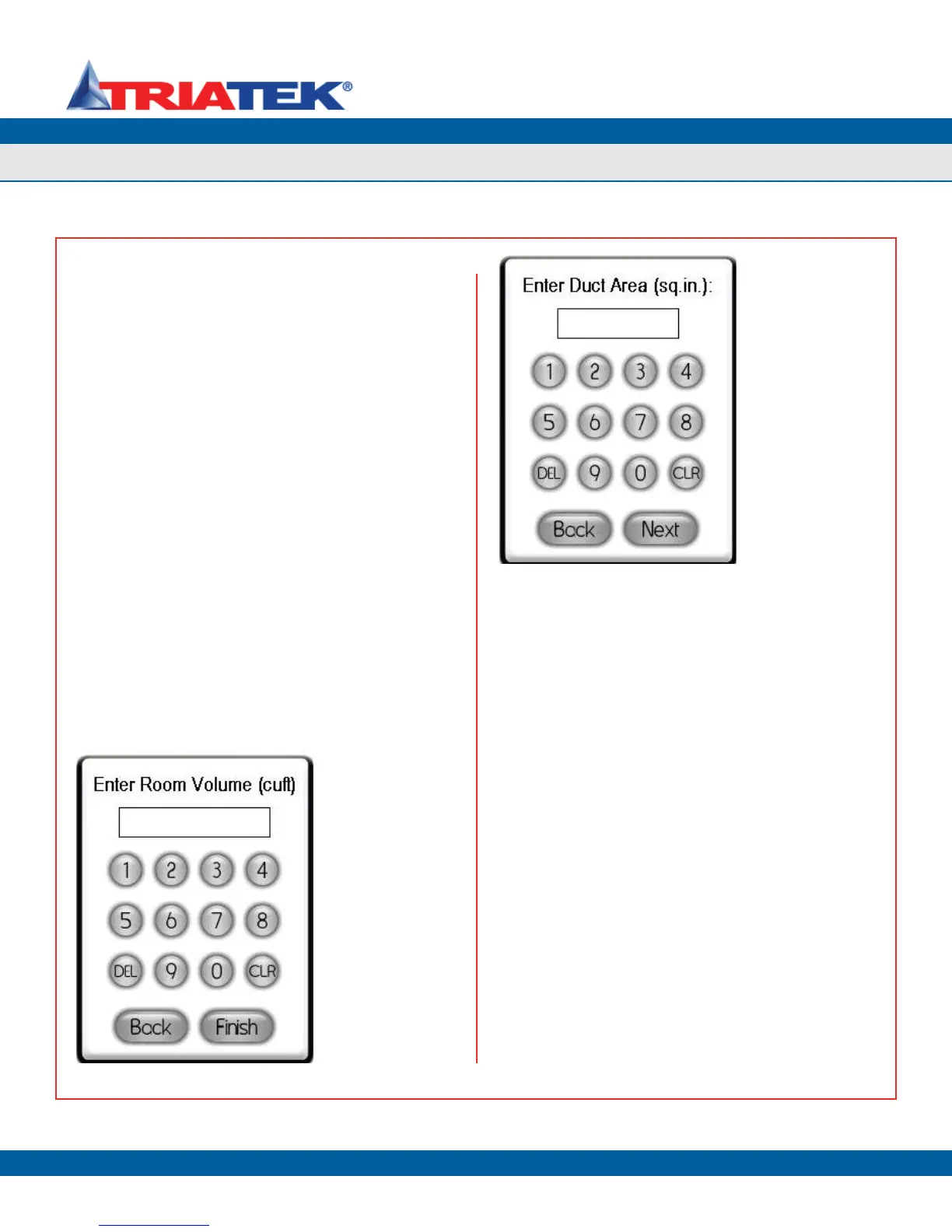

Clicking the Next button invokes the Analog Input x Settings

configuration screen as shown in Figure 41, where the user may

specify whether or not air changes should be calculated and displayed

on the main screen, as well as the range of the input signal (voltage

or current) for the air flow sensor. If the air changes have been

selected for display, the user is prompted to enter the room volume in

cubic feet at the Enter Room Volume configuration screen shown in

Figure 42. The room volume is required to calculate the real-time air

change rate based on the flow input signal. To calculate the volume

of a rectangular room in cubic feet, multiply the length of the room by

the width and the height. For irregular shaped rooms, the volume will

have to be determined by breaking the room up into multiple smaller

rectangular areas and summing the individual volumes to calculate the

total room volume in cubic feet. Otherwise, an approximation may be

specified for the room volume. This volume may also be fine-tuned to

increase the accuracy of the displayed air change rate according to the

actual volumetric flow offset of the room.

If air changes have been selected for display and the flow

measurement device is an actual air flow sensor, then clicking the

Next button invokes the configuration screen shown below in Figure

42, which allows the user to specify the volume of the room being

monitored. The room volume is required to calculate the air change

rate.

Setting up Analog Inputs for Humidity

The FMS-1650 can be configured to measure and display humidity

in real-time using readily available sensors from BAPI® and other

manufacturers. To configure one of the secondary analog inputs for

humidity measurement, select Humidity from the Select Input Type

configuration screen (Figure 44) and click the Next button. The Analog

Input x Settings configuration screen shown in Figure 45 appears,

allowing the user to select the engineering units and voltage or current

input range for the connected sensor.

If the humidity input is being utilized for a humidity control scheme,

then clicking the Next button at the popup shown in Figure 45 invokes

the setpoint entry configuration screen shown in Figure 46 where the

user may enter a target humidity setpoint. The humidity input must

also be mapped to one of the analog outputs that has been configured

for PID control mode.

Figure 42. The room

volume in cubic feet

should be entered here

to allow the air change

rate to be calculated.

Figure 43. To

allow velocity or

velocity pressure

measurements to be

converted to flow, the

duct area is required in

square inches.

Loading...

Loading...