SYSTEM SETUP

Confi guring Secondary Analog Inputs

FMS-1650

TRIATEK reserves the right to change product specifications without notice.

- 22 -

whether or not the analog input signal should be inverted. The

Inverted Mode option is useful for those situations where the remote

sensor was installed backwards with the reference port facing the

monitored space instead of the reference space. Clicking the Next

button invokes the next Analog Input Settings configuration screen

where the displayed engineering units may be specified, as well as the

voltage or current range for the analog input signal.

For all Triatek remote sensor units, the default pressure range is ±0.25

“WC and the input range should be set to 4-20mA. Clicking the Next

button invokes the AI-x Sensor Range configuration screen (Figure 9)

where the pressure range associated with the remote sensor should

be specified. Once the pressure range has been specified, the user

is prompted to enter a setpoint for the currently active isolation mode,

as well as the deadband setting to be used for all modes. The default

deadband setting is zero.

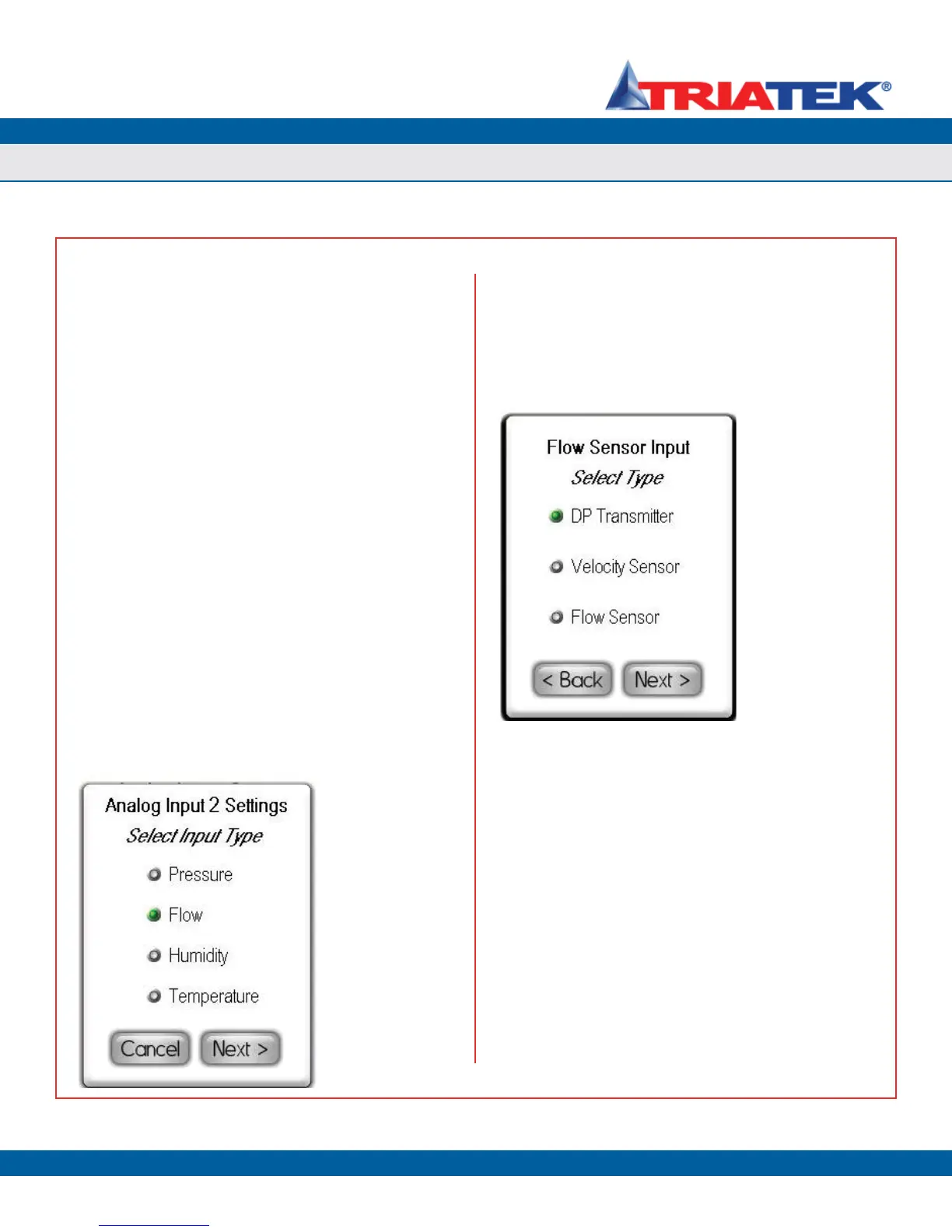

Setting up Analog Inputs for Flow

The FMS-1650 can be configured to calculate and display the real-time

Air Change Rate using one of three types of air flow input methods or

sensors. To configure one of the secondary analog inputs for air flow

measurement, select Flow from the Select Input Type configuration

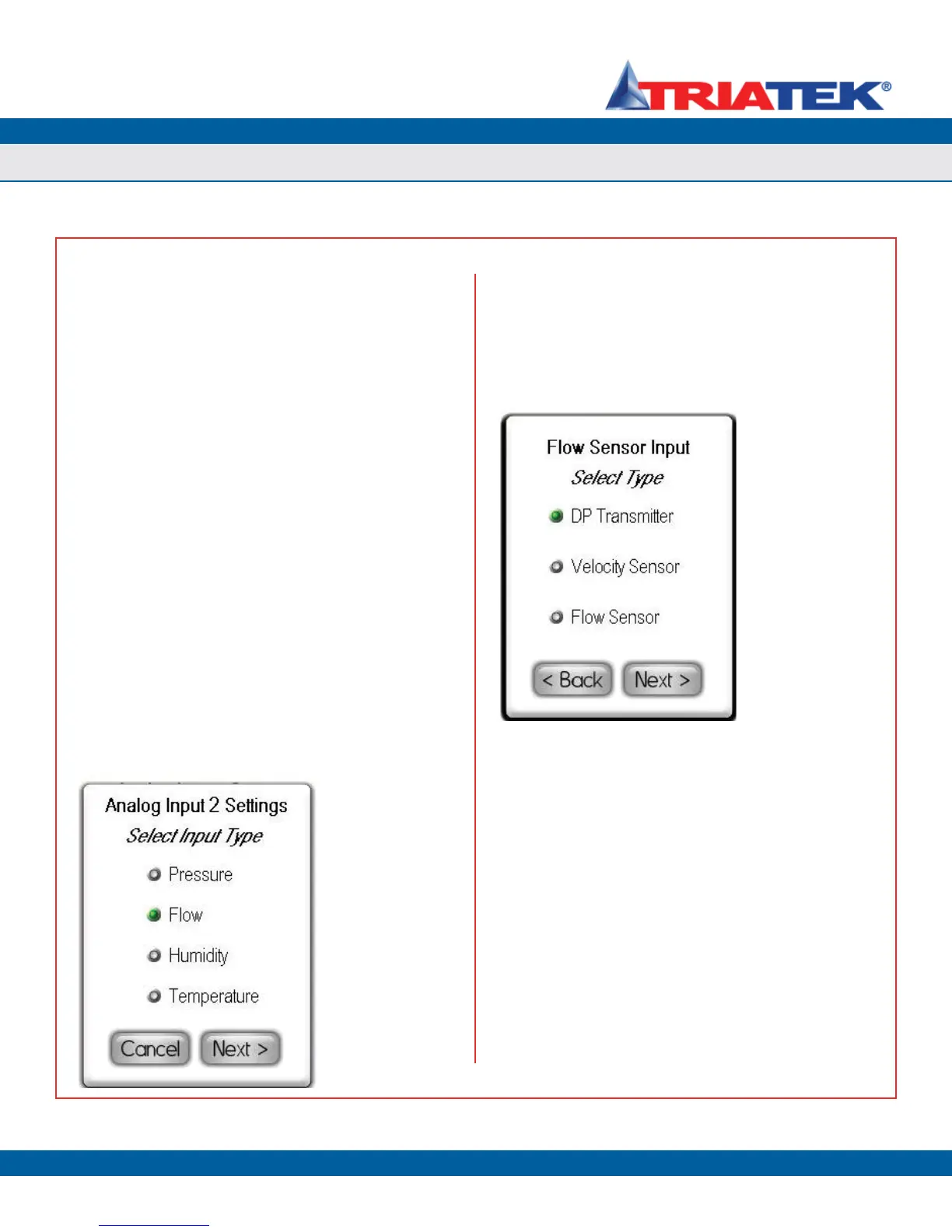

screen as shown in Figure 38 and click the Next button. The Flow

Sensor Input configuration screen shown in Figure 39 appears,

allowing the user to select which type of sensor will be used for

measuring air flow.

After selecting the type of sensor that is being used to measure

air flow, clicking the Next button invokes two configuration screens

(Figure 40) which allow the user to specify the minimum and maximum

flows supported by the sensor. These values should be entered in

the engineering units which correspond to the type of sensor. For

example, the units would be either inches of water column (“WC) or

Pascals (Pa) for DP transmitters.

After specifying the maximum and minimum for the flow input, the

user is prompted to specify the cross-sectional duct area in square

inches as shown in Figure 43 if the type of flow sensor is either a

DP transmitter or a velocity transmitter. This duct area is required to

convert a differential pressure or a velocity to a real-time volumetric

flow, which may then used to calculate the air change rate (if enabled).

For round ducts, the cross-sectional area can be determined by

multiplying the square of the radius by pi (3.1416). As an example, the

cross-sectional area of a round 12” duct, which has a radius of 6”, is

calculated as follows:

Area

round duct

= π * r

2

= 3.1416 * (6”)

2

= 113.09 in

2

For rectangular ducts, the cross-sectional area can be determined by

multiplying the length and width. As an example, the cross-sectional

area of a duct that measures 24” by 12” is calculated as follows:

Area

rectangular duct

= L * W = 24” * 12” = 288 in

2

Figure 38. To calculate

& display air change

rate, input should be

configured for flow.

Figure 39. FMS-1650

supports three types

of sensors for Air Flow

measurement.

Loading...

Loading...