PID TUTORIAL

FMS-1650

TRIATEK reserves the right to change product specifications without notice.

- 64 -

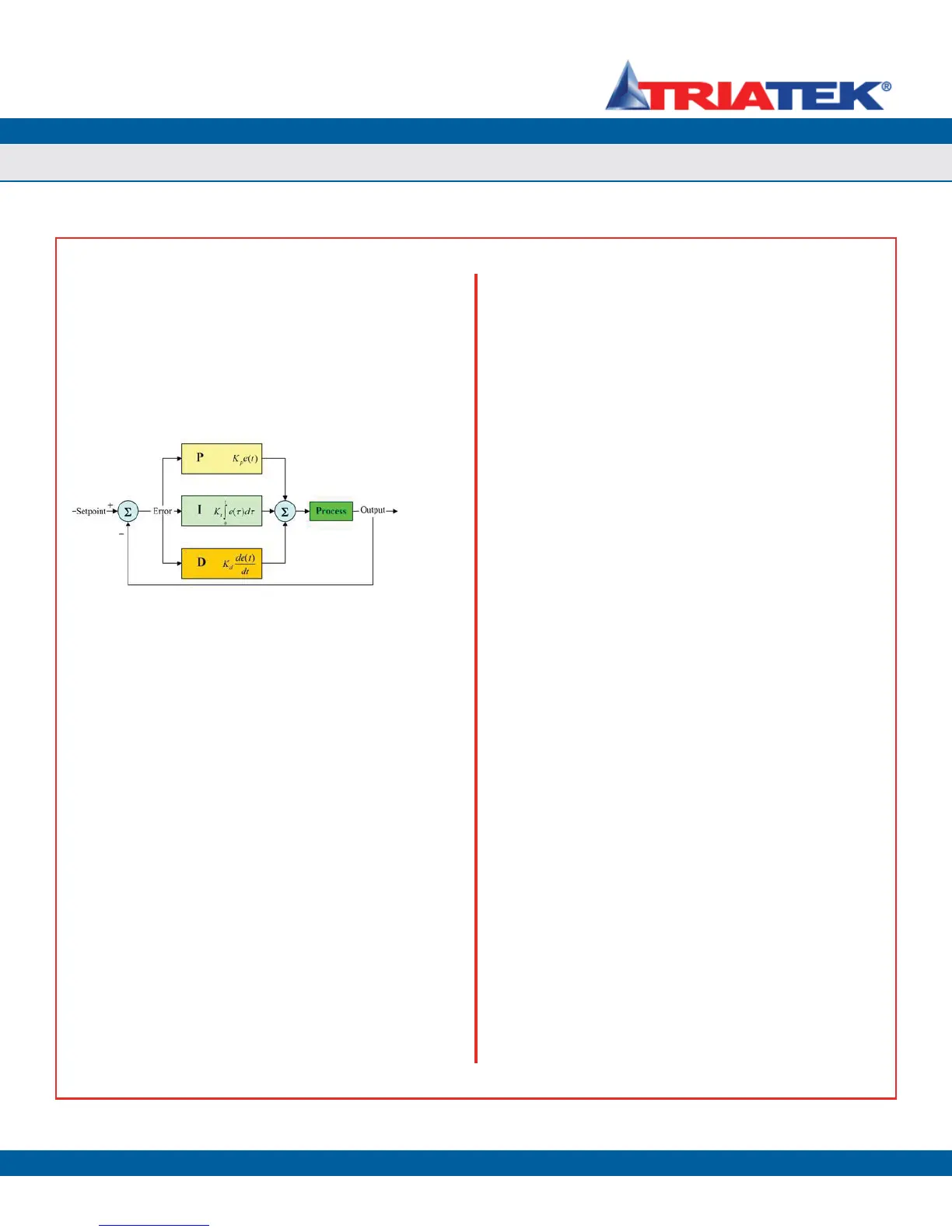

PID is an acronym that stands for Proportional-Integral-Derivative, and

is a generic closed-loop control mechanism that is commonly used in

many industrial control systems. It is by far the most commonly used

feedback controller in use today. A controller which implements PID

mode continuously calculates the difference (or error signal) between

a measured process variable (PV) and a desired setpoint (SP). The

PID controller attempts to minimize this error by adjusting the process

control inputs, also referred to as the manipulated variable (MV). A

block diagram of a PID controller is shown in Figure 106.

The PID controller algorithm consists of three parameters: proportional,

integral, and derivative. In terms of time, the proportional term

depends on the present error, the integral term depends on the

accumulation of past errors, and the derivative term is a prediction

of future errors. The weighted sum of these three terms is used to

adjust the process via a control variable such as the position of a

control valve of the power applied to a heating element. In the case

of applications for the FMS-1650 as a room pressure controller, the

process variable is the differential pressure and the control variable is

typically the position of an exhaust damper.

By tuning the PID parameters or constants in the algorithm, the

controller can provide control action designed for specific process

requirements. The response of the controller can be described in

terms of the responsiveness of the controller to an error, the degree

to which the controller overshoots the setpoint, and the degree of

system oscillation. Some applications may require using only one or

two terms to provide the appropriate system control. This is achieved

by setting the constant(s) of the undesired control output(s) to zero.

The variations include PI, PD, P, or I controllers in the absence of the

respective control actions. PI controllers are relatively common, since

the derivative term is sensitive to measurement noise, whereas the

absence of an integral value may prevent the system from reaching its

target value due to the control action.

A typical example of a closed-loop control scheme is when the hot

and cold valves of a faucet are adjusted to maintain the water from the

faucet at a desired temperature. This involves the mixing of the two

process streams, the hot and cold water. Touching the water allows

the temperature to be sensed or “measured.” Based on this feedback

of sensing the water temperature, a control action may be performed

to adjust the hot and cold water valves until the process temperature

stabilizes at the desired value.

Sensing the water temperature is analogous to taking a measurement

of the process variable (PV), while the desired temperature is referred

to as the setpoint (SP). The input to the process (water valve position)

is referred to as the manipulated variable (MV). The difference

between the “measured” temperature and the setpoint is the error (e)

and quantifies whether the water is too hot or too cold, and by how

much. After measuring the temperature (PV), and then calculating

the error, the controller decides when to change the tap position (MV)

and by how much. When the controller first turns the valve on, it may

turn the hot valve only slightly if warm water is desired, or it may open

the valve all the way if very hot water is desired. This is an example

of a simple proportional control. In the event that hot water does

not arrive quickly, the controller may try to speed-up the process by

opening up the hot water valve more as time goes by. This is an

example of an integral control.

PID Controller Theory

The PID closed-loop control scheme is named after its three correcting

terms, whose sum constitutes the manipulated variable (MV):

MV(t) = P

out

+ I

out

+ D

out

where P

out

, I

out

,

and D

out

are the contributions to the output from

the PID controller from each of the three terms, as defined in the

subsequent sections below.

Proportional Term

The proportional term (sometimes referred to as gain) makes a change

to the output that is proportional to the current error value. The

proportional response can be adjusted by multiplying the error by a

constant K

p

called the proportional gain. The proportional term of the

output is given by:

K

p

: proportional constant (tuning parameter)

SP: setpoint or desired value

Figure 106. Block

diagram of a PID

controller.

TRIATEK reserves the right to change product specifications without notice.

PID Tutorial

Loading...

Loading...