PID TUTORIAL

FMS-1650

- 65 -

PV: process variable or measured value

e: error = SP – PV

t: time or instantaneous time (the present)

A high proportional gain results in a large change in the output for

a given change in the error. If the proportional gain is too high, the

system may become unstable. In contrast, a small gain results in a

small output response to a large input error, and a less responsive (i.e,

slower) controller. If the proportional gain is too low, the control action

may be too small when responding to system disturbances. For most

closed-loop control schemes, the proportional gain should contribute

the bulk of the output change.

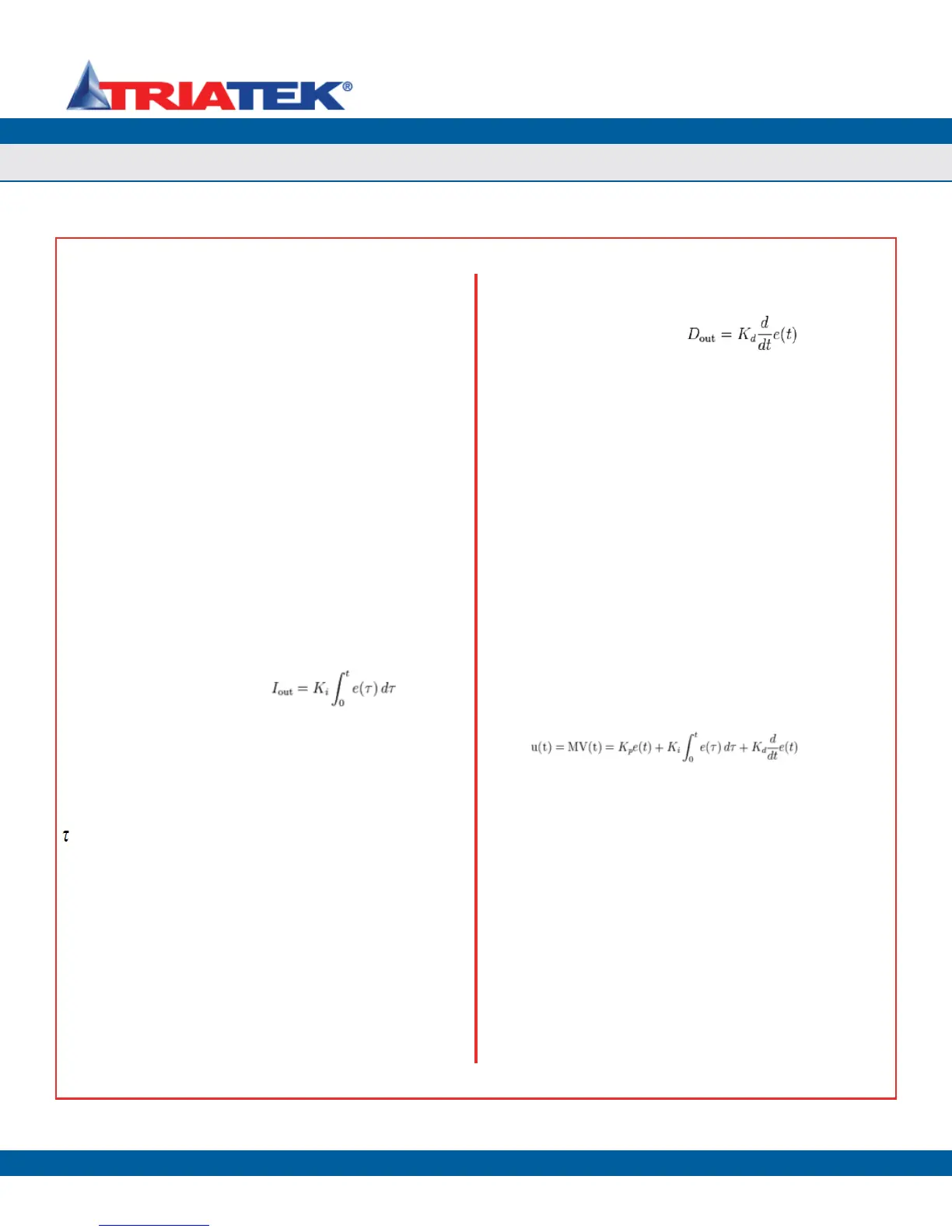

Integral Term

The integral term (sometimes referred to as reset) is proportional to

both the magnitude of the error and the duration of the error. Summing

the instantaneous error over time (integrating the error) gives the

accumulated offset that should have been corrected previously. The

accumulated error is then multiplied by the integral gain and added to

the controller output. The magnitude of the contribution of the integral

term to the overall control action is determined by the integral gain, K

i

.

The integral term is given by:

where:

K

i

: integral constant (tuning parameter)

SP: setpoint or desired value

PV: process variable or measured value

e: error = SP – PV

t: time or instantaneous time (the present)

: dummy integration variable

The integral term, when added to the proportional term calculated

above, accelerates the movement of the process towards setpoint

and eliminates the residual steady-state error that occurs with a

proportional-only control scheme. However, since the integral term

is responding to accumulated errors from the past, it can cause the

present value to overshoot the setpoint value (cross over the setpoint

and then create a deviation in the other direction).

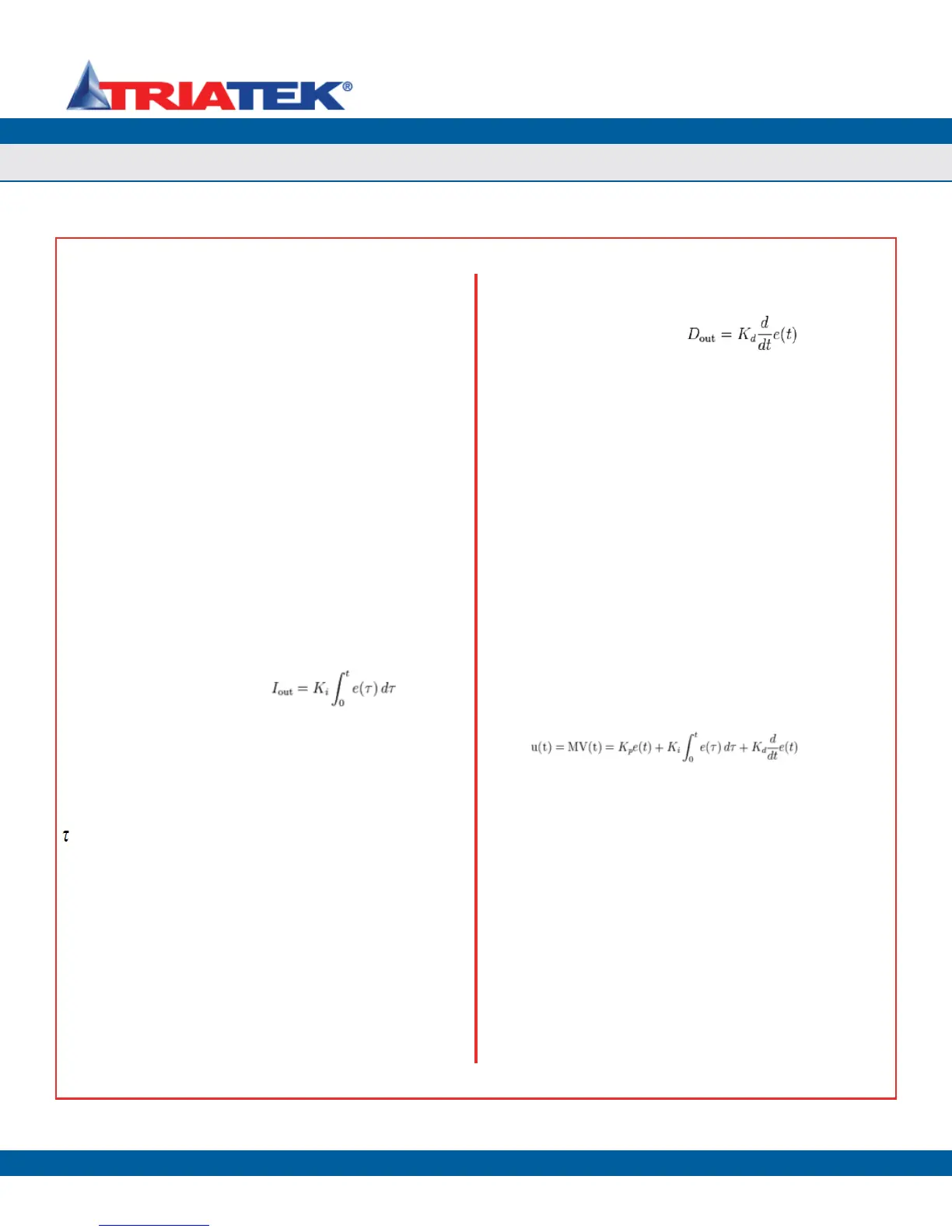

Derivative Term

The rate of change of the process error is calculated by determining

the slope of the error over time (i.e., its first derivative with respect to

time) and multiplying this rate of change by the derivative gain K

d

. The

magnitude of the contribution of the derivative term (sometimes called

rate) to the overall control action is termed the derivative gain, K

d

.

The derivative term is given by:

where:

K

d

: derivative constant (tuning parameter)

SP: setpoint or desired value

PV: process variable or measured value

e: error = SP – PV

t: time or instantaneous time (the present)

The derivative term slows the rate of change of the controller output

and this effect is most noticeable close to the controller setpoint.

Hence, derivative control is used to reduce the magnitude of the

overshoot produced by the integral component and improve the

combined controller-process stability. However, the differentiation of

a signal amplifies noise and thus this term in the controller is highly

sensitive to noise in the error term, and can cause a process to

become unstable if the noise and the derivative gain are sufficiently

large.

The proportional, integral, and derivative terms are summed to

calculate the output of the PID controller. Defining u(t) as the controller

output, the final form of the PID algorithm is:

where the tuning parameters are:

Proportional gain, K

p

Larger values typically mean faster response since the

larger the error, the larger the proportional term compensation. An

excessively large proportional gain will lead to process instability and

oscillation.

Integral gain, K

i

Larger values imply steady-state errors are eliminated more

quickly. The trade-off is larger overshoot: any negative error integrated

during transient response must be integrated away by positive error

before reaching steady-state.

Derivative gain, K

d

Larger values decrease overshoot, but slow down transient

response and may lead to instability due to signal noise amplification in

the differentiation of the error.

TRIATEK reserves the right to change product specifications without notice.

PID Tutorial

Loading...

Loading...