Page: 3-5

WALKER MANUFACTURING COMPANY

July 2006

SERVICE INSTRUCTIONS

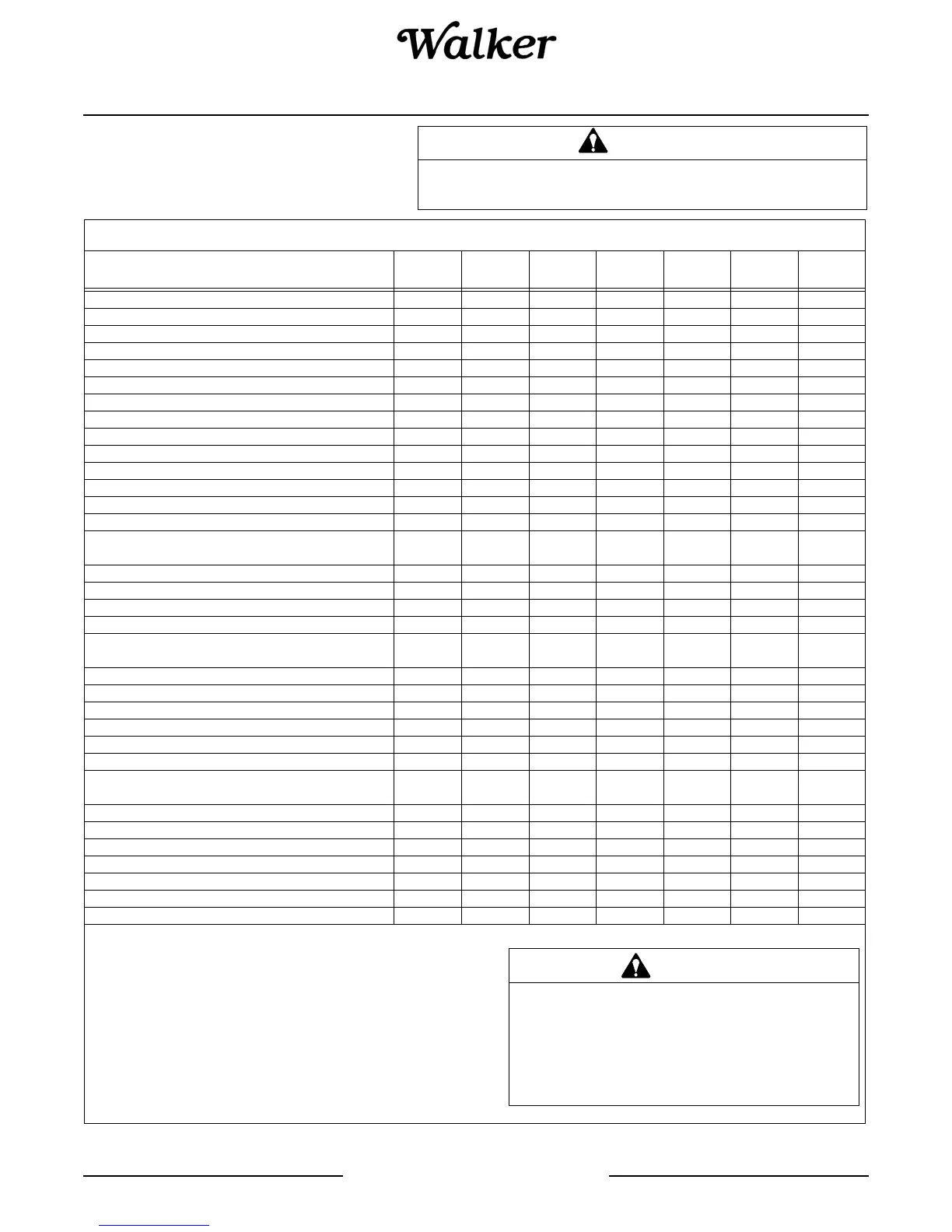

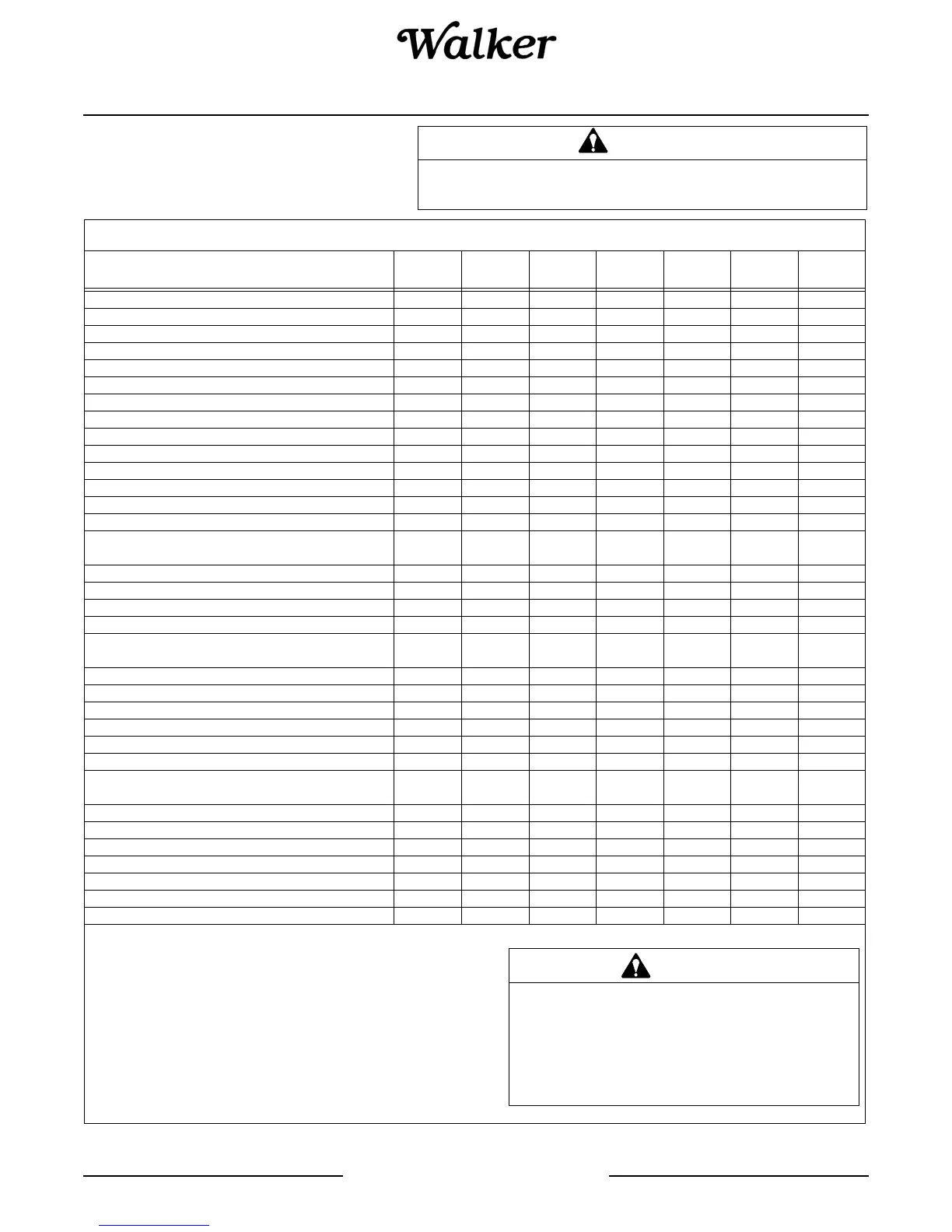

MAINTENANCE SCHEDULE CHART - RECOMMENDED SERVICE INTERVALS - MODEL MC

Service Item

Daily

25

Hours

100

Hours

200

Hours Yearly

Every

2Years

Ref.

Page

Check Engine Crankcase Oil Level x 2-3

Check/Clean Engine Air Cooling System* x 3-24

Check Security of Air Filtration Components x 3-12

Check Air Filter Restriction Gauge x 3-22

Clean Grass Buildup Under Deck x 3-28

Clean GHS Exhaust Screen* x 3-30

Clean GHS Blower* x 3-29

Service Mower Blades x 3-13

Check Function of Oil Pressure Warning Light x

Lubricate Grease Fittings and Oil Points* x 2-15

Check PTO Gearbox Oil Level** x 2-10

Check Battery Electrolyte Level x

Check Hydrostatic Transmission Fluid x 2-13

Check Tire Pressure x 3-12

Check Drive Belts (Jackshaft, Engine PTO,

GHS Blower, Ground Drive)

x3-14

Check Gearbox Oil Seals x 3-15

Check Turbine Precleaner* x 3-18

Check/Clean Air Filter Element

Δ

x3-22

Change Engine Crankcase Oil

ΔΔ

x2-5

Check/Adjust Blade Clutch (PTO)/

Brake Action

x x 3-17

Check Oil Level in Gear Axle x 2-13

Clean Hydrostatic Transmission Cooling Fins x 3-30

Clean Engine Cooling Fins x 3-24

Check/Regap Spark Plugs x

Change Engine Oil Filter x 2-5

Check Fuel Lines and Clamps x 3-15

Replace Air Filter Element

and Vacuator™ Valve

Δ

x3-22

Replace Fuel Filter x4-24

Service Battery x3-12

Check/Adjust FSC Friction Lock x 4-59

Service Solenoid Shift Starter x 3-15

Check Engine Valve Clearance x 3-15

Change Gear Axle Oil

ΔΔΔ

x2-13

Replace Fuel Lines and Clamps x 3-15

∗ More often in extremely dusty or dirty conditions

∗∗ Change PTO gearbox oil after first 100 hours

of operation (break-in period)

Δ Air cleaner is remote mounted Donaldson Radialseal™

unit, replace filter every year or after 6 cleanings

ΔΔ Change engine oil and filter after first 5 hours of

operation of a new engine (break-in period)

ΔΔΔ Change every 2 years or 1000 hours

CAUTION

Maintenance procedures requiring special training or

tools should be performed by a trained technician.

CAUTION

When performing maintenance with the

mower body raised, a safety prop should

be installed from back of body to chassis

frame (fail-safe protection in case of fail-

ure of body lift support). For GHS Model,

empty grass catcher before raising body.

Loading...

Loading...