Page: 4-60

WALKER MANUFACTURING COMPANY

July 2006

SERVICE INSTRUCTIONS

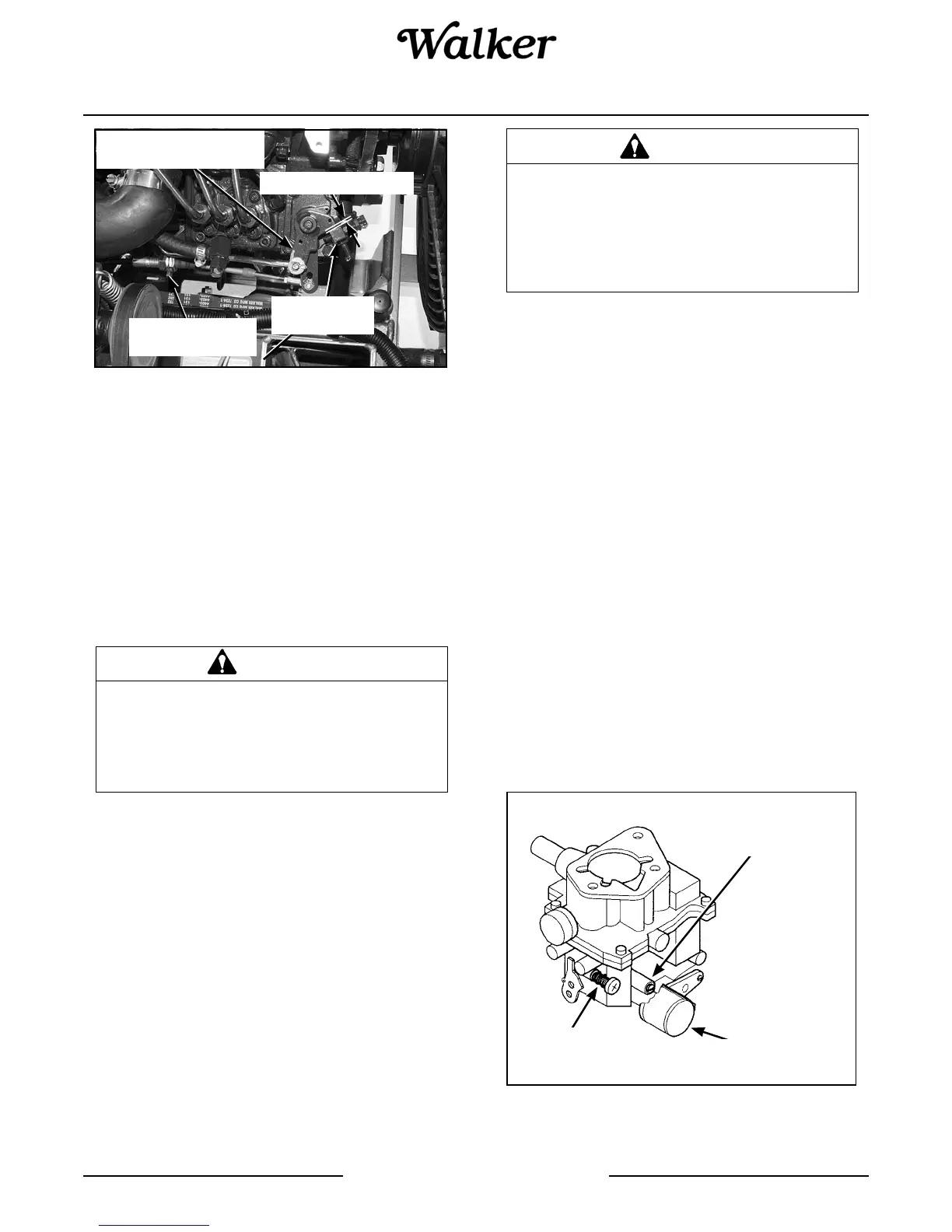

Fuel Valve Solenoid Linkage Adjustment

(shown with air intake hose removed for clarity)

2. If the gap is incorrect, adjust the linkage by loos-

ening the jam nut at the solenoid, removing the

cotter pin and washer from the connection to the

fuel valve control arm, and screwing the linkage

rod in or out of the solenoid ball joint as required.

3. After adjusting the linkage for the proper gap,

turn the ignition key ON, and check the gap by op-

erating the solenoid.

Carburetor - Model MC, MT

The fixed main jet carburetor is designed to deliver the

correct fuel-to-air mixture to the engine under all oper-

ating conditions. The high idle is set at the factory and

cannot be adjusted. The low idle mixture screw is also

set at the factory and normally does not need adjust-

ment. The only adjustment normally made to the car-

buretor is to set the idle speed. However, if the engine

exhibits any of the following symptoms, it may be nec-

essary to adjust or service the carburetor: black, sooty

exhaust smoke; lack of power; engine miss or backfire;

hard to start; rough running; stalls at low idle speed.

NOTE: Due to the technical requirements of modern

carburetors, refer to the Kohler Service Manual or con-

tact an authorized Kohler engine dealer for carburetor

adjustments and service not described in this section.

Since the carburetor main jet is non-adjustable, for op-

eration above 5000 ft (1,524 m) above sea level, it may

be necessary to change the carburetor main jet for best

fuel economy and power. Contact an authorized Kohler

dealer to change the carburetor main jet.

Engine Idle Adjustment

IMPORTANT: Some emission certified engines may

not have an adjustable idle mixture needle valve; it is

fixed from the factory and the adjustable screw is

"capped". In this case, only the idle speed is adjust-

able and only Step 4 of the instructions below applies.

1. Gently close the idle mixture needle valve by turn-

ing it clockwise until it bottoms lightly.

IMPORTANT: The needle valve and carburetor

seat may be damaged by turning the adjustment

screw too tight.

2. Preliminary Setting: Turn the idle mixture needle

valve out (counterclockwise) 1-1/2 turns from the

closed position. This initial adjustment will allow

the engine to be started and warmed up prior to the

final adjustment.

Carburetor Adjustment

CAUTION

DO NOT change the engine governor set-

tings or overspeed the engine. The gov-

ernor has been factory set for maximum

safe engine operating speed.

1/16 in. (1.6 mm) Gap

Control Valve

Stop

Solenoid Linkage

Rod and Jam Nut

Fuel Valve Control Arm

in Open (Run) Position

CAUTION

ALWAYS use the proper engine service

manual when working on the engine. Un-

authorized maintenance operations or

modifications to the engine MAY result in

unsafe operating conditions.

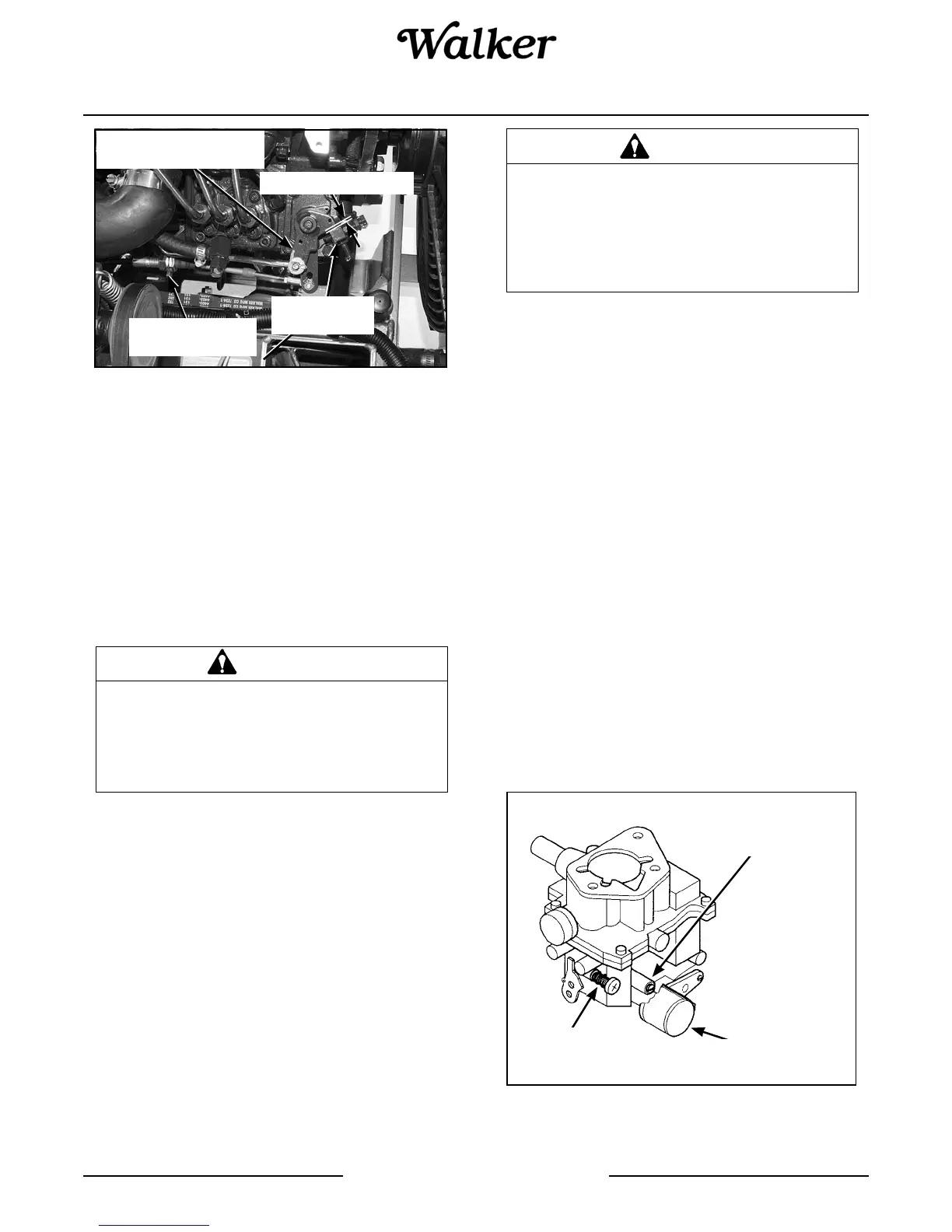

Low Idle Mixture

Needle Valve

(May be Non-Adjustable)

Fixed Main Jet Under

Shutdown Solenoid

Idle Speed

Screw

Loading...

Loading...