Page: 4-50

WALKER MANUFACTURING COMPANY

July 2006

SERVICE INSTRUCTIONS

Use the following procedures to check and adjust clutch

disengagement and brake action:

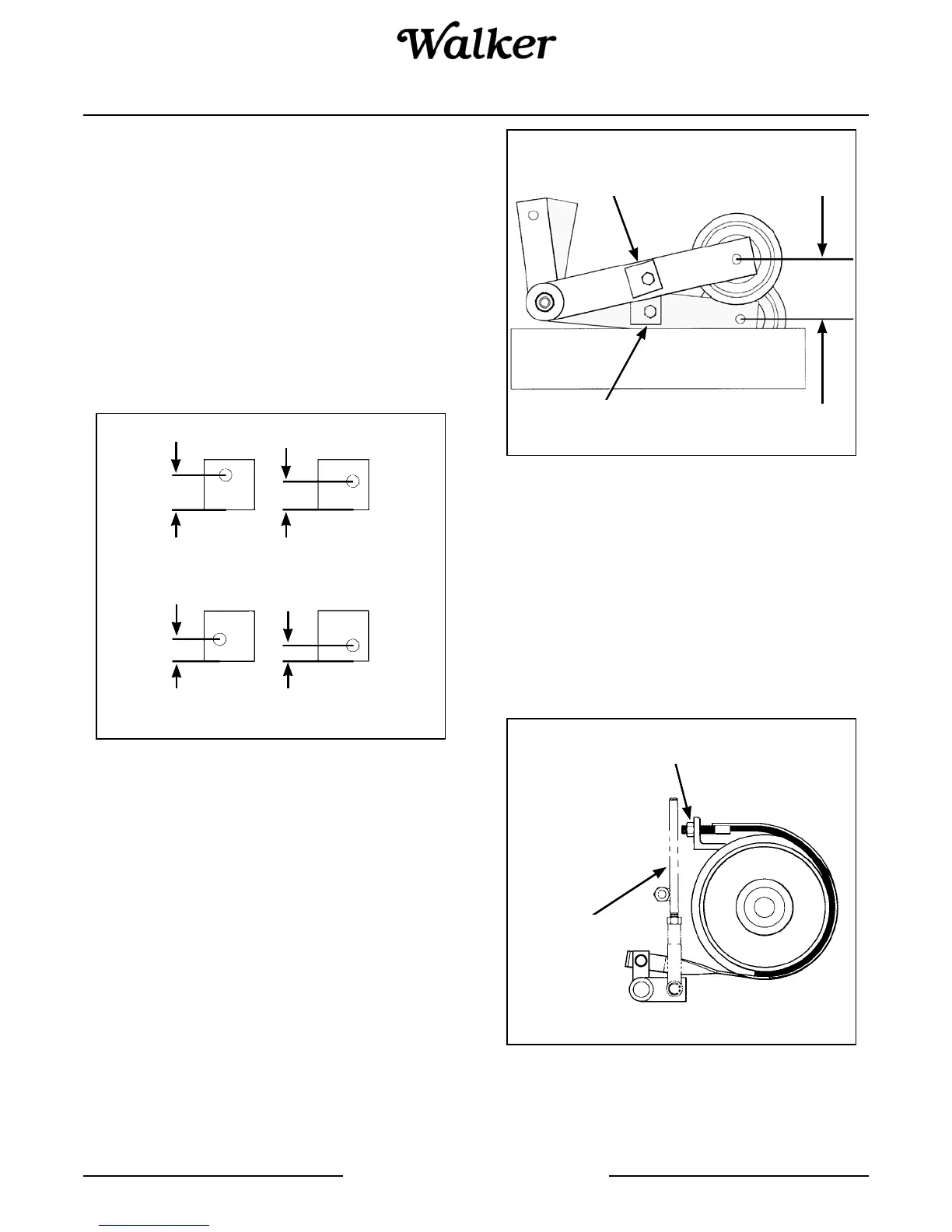

Stop Block Eccentric Adjustment - Step 1

Use the stop block attached to PTO belt tightener arm

to set the bottom position of the clutch idler pulley in the

disengaged position. The stop block should contact

the chassis to stop the clutch idler pulley from moving

further down in the disengaged position. If the stop

block is not contacting the chassis in the disen-

gaged position, it will be necessary to loosen the

brake band adjustment nut. The stop block is an “ec-

centric” block that will allow four adjustment positions

from 5/16 in. (8 mm) to 11/16 in. (17 mm).

PTO Belt Tightener Stop Block Adjustments

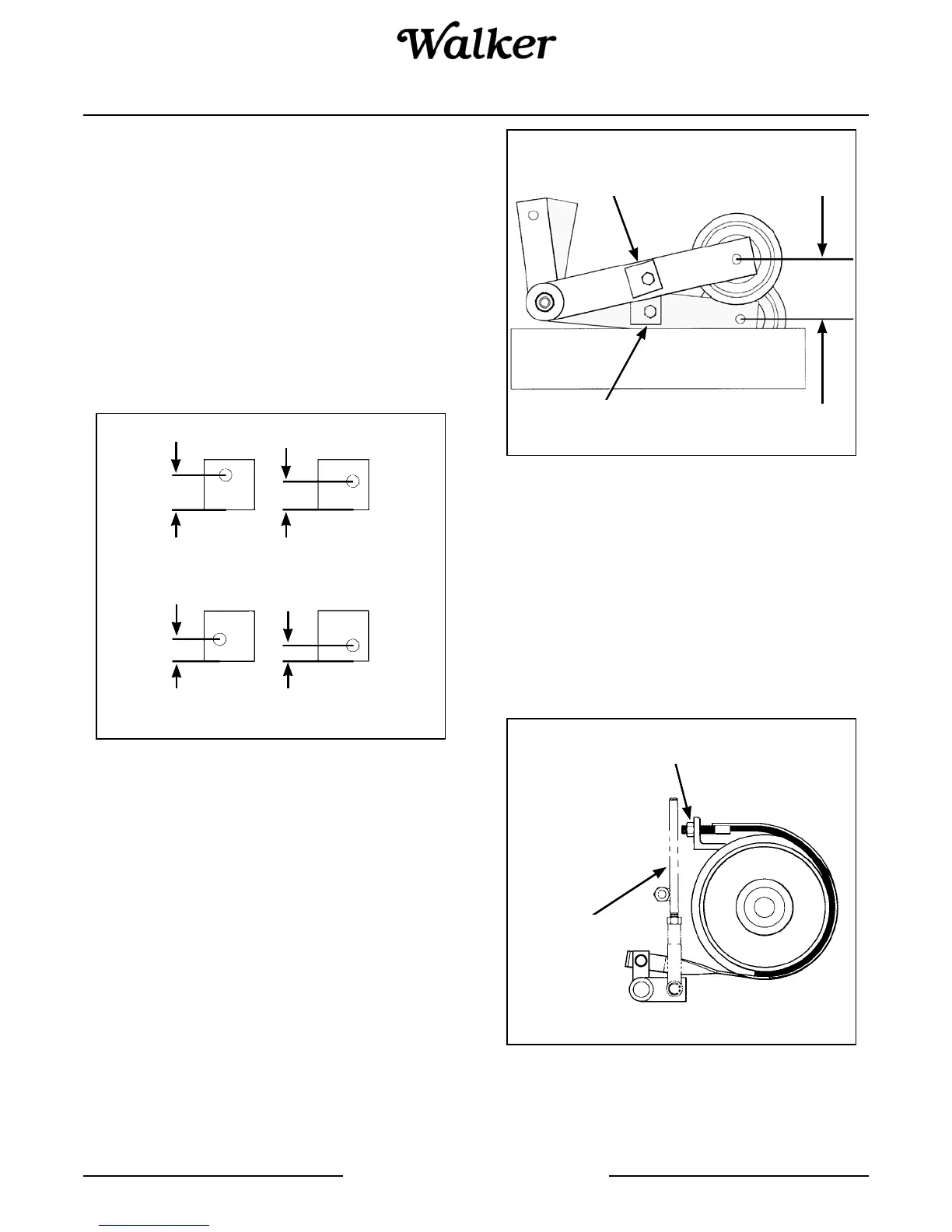

Clutch Idler Pulley Travel Adjustment - Step 2

Adjust the stop block to give 1 in. (25 mm) to 1-1/2 in.

(38 mm) pulley travel from “clutch engaged” to “clutch

disengaged”. To check and adjust the pulley travel,

first engage the clutch, then measure the distance the

pulley moves down as the clutch is disengaged and the

stop block contacts the frame.

NOTE: The importance of this adjustment is if the pul-

ley travel is excessive and the belt develops too much

slack, the belt will derail when disengaged.

Clutch Idler Pulley Travel Adjustment

Blade Brake Band Adjustment - Step 3

After the pulley travel is set, make the following adjust-

ment as needed:

1. Adjust the blade brake band, using the adjustment

nut until there is a gap of approximately 1/8 in. (3

mm) between the PTO belt tightener stop block

and chassis. If there are not enough threads on

the brake band for adjustment, lengthen the brake

actuator rod.

Blade Brake Band Adjustment

11/16 in.

(17 mm)

9/16 in.

(14 mm)

7/16 in.

(11 mm)

5/16 in.

(8 mm)

Engage

Disengage

Pulley

Travel

1 in. to 1-1/2 in.

(25 mm to 38 mm)

Stop Block

Contacting Frame

Stop

Block

Brake Actuator

Rod

Blade Brake Band

Adjustment Nut

Loading...

Loading...